Synthesis method of layered rhenium-nitrogen compound ReN2

A synthesis method and compound technology, which is applied in the field of transition metal compound synthesis, can solve the problems of cumbersome operation and increased investment in experimental resources, and achieve the effects of good synthesis safety, simple experimental preparation process, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 layered ReN 2 Synthesis

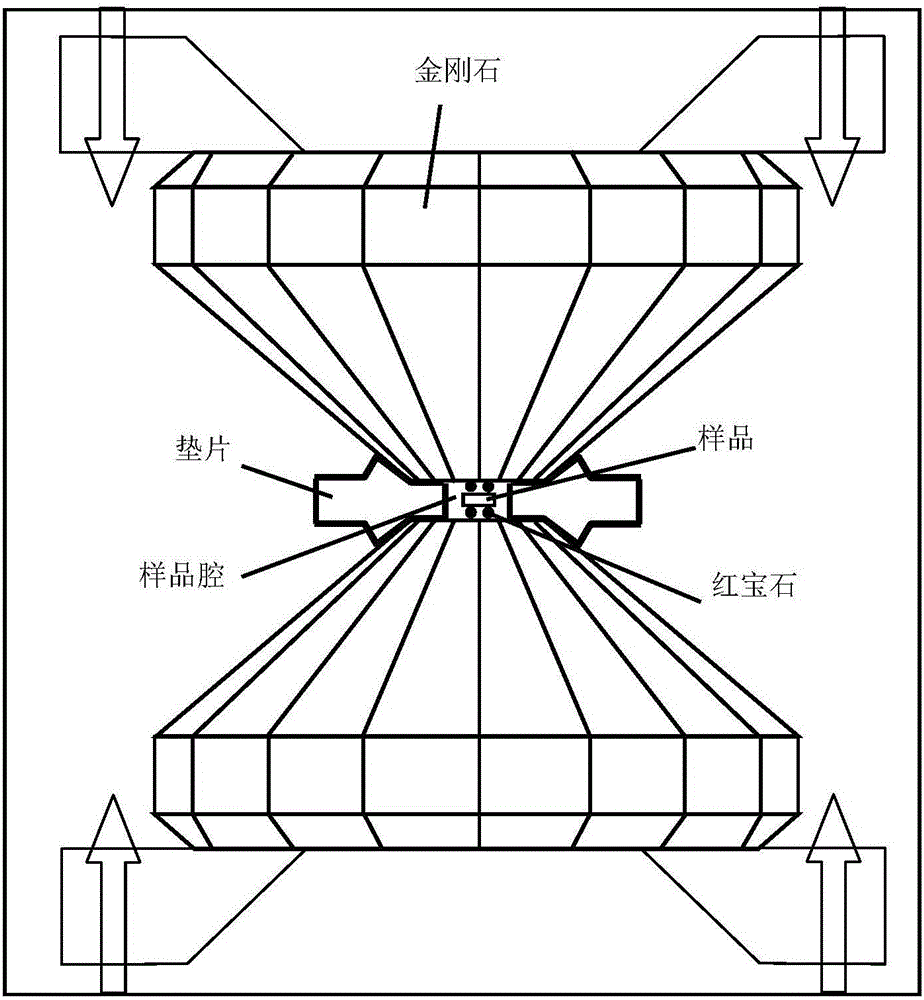

[0020] Choose a DAC device with a diamond anvil surface of 300 μm (such as figure 1 ), using rhenium sheet as the gasket material, the rhenium sheet was pre-pressed to a thickness of 40 μm with a DAC device, and a hole with a diameter of 140 μm was punched in the center of the indentation with an electric spark puncher as a sample cavity. In order to reduce the damage caused by laser heating to the diamond anvil, four rubies with a particle size of 20-30 μm were placed on the upper and lower anvil surfaces of the DAC device as a heat insulation layer to avoid contact between the reactants and the diamond anvil surface. To calibrate the pressure in the sample chamber. Rhenium powder and NaN 3 Mix well in a mortar with a ratio of 1:2, pick a piece of Re, NaN after grinding 3 The mixture sample is put into the sample cavity, the sample diameter is 80 μm, and the thickness is 30 μm. The DAC device is closed and placed in liquid argon,...

Embodiment 2

[0023] Example 2 layered ReN 2 Characterization by X-ray Diffraction Pattern

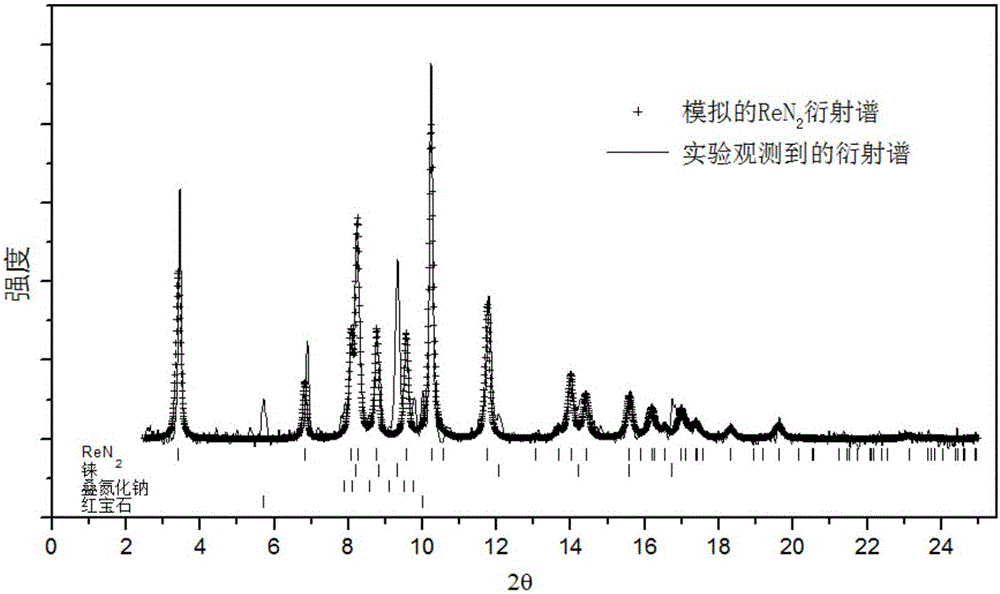

[0024] Using the Advanced Photon Source APS (Advanced Photon Source) of the Argonne National Laboratory in the United States to collect synchrotron radiation X-ray diffraction data, the wavelength of the light source Spectrum acquisition time 5s. The directly obtained two-dimensional diffraction image was converted into a one-dimensional image of peak intensity versus diffraction angle by FIT2D software. Then use the Reflexmodule module in the MaterialsStudio7.0program to analyze the XRD image and match the peak position. (XRD pattern see image 3 )

[0025] The XRD pattern can be compared with the layered MoS reported in the previous literature 2 Type ReN 2 Matching (space group P63 / mmc), the lattice parameters obtained by structure refinement are XRD spectrum except ReN 2 There are also some miscellaneous peaks in the diffraction peaks. Through peak position identification, it can be det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com