Raw material gas supply apparatus for semiconductor manufacturing equipment

a gas supply apparatus and semiconductor technology, applied in the direction of transportation and packaging, chemical vapor deposition coating, coating, etc., to achieve the effect of improving the controllability of the flow rate and accurately controlling the flow rate of the supplied gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

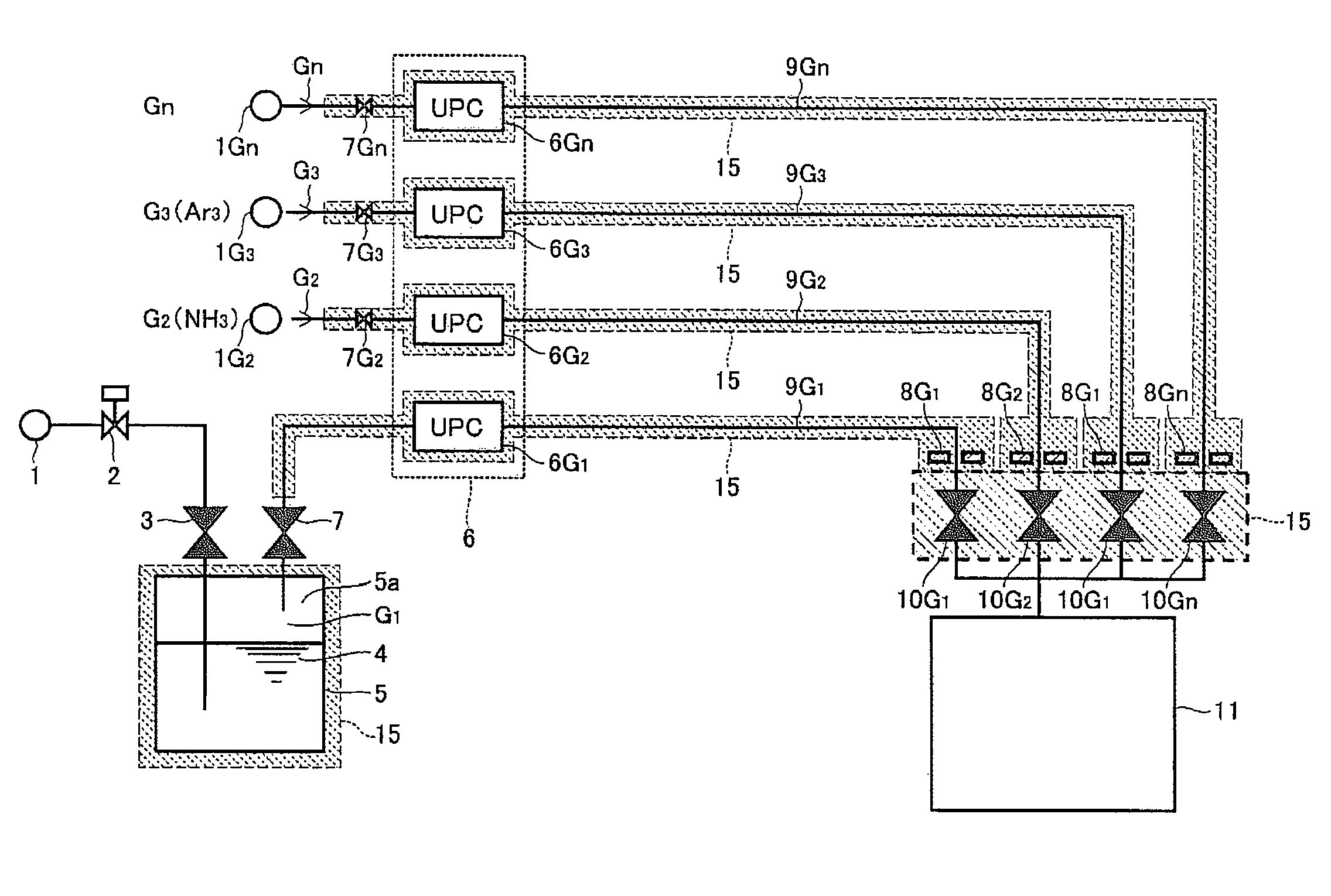

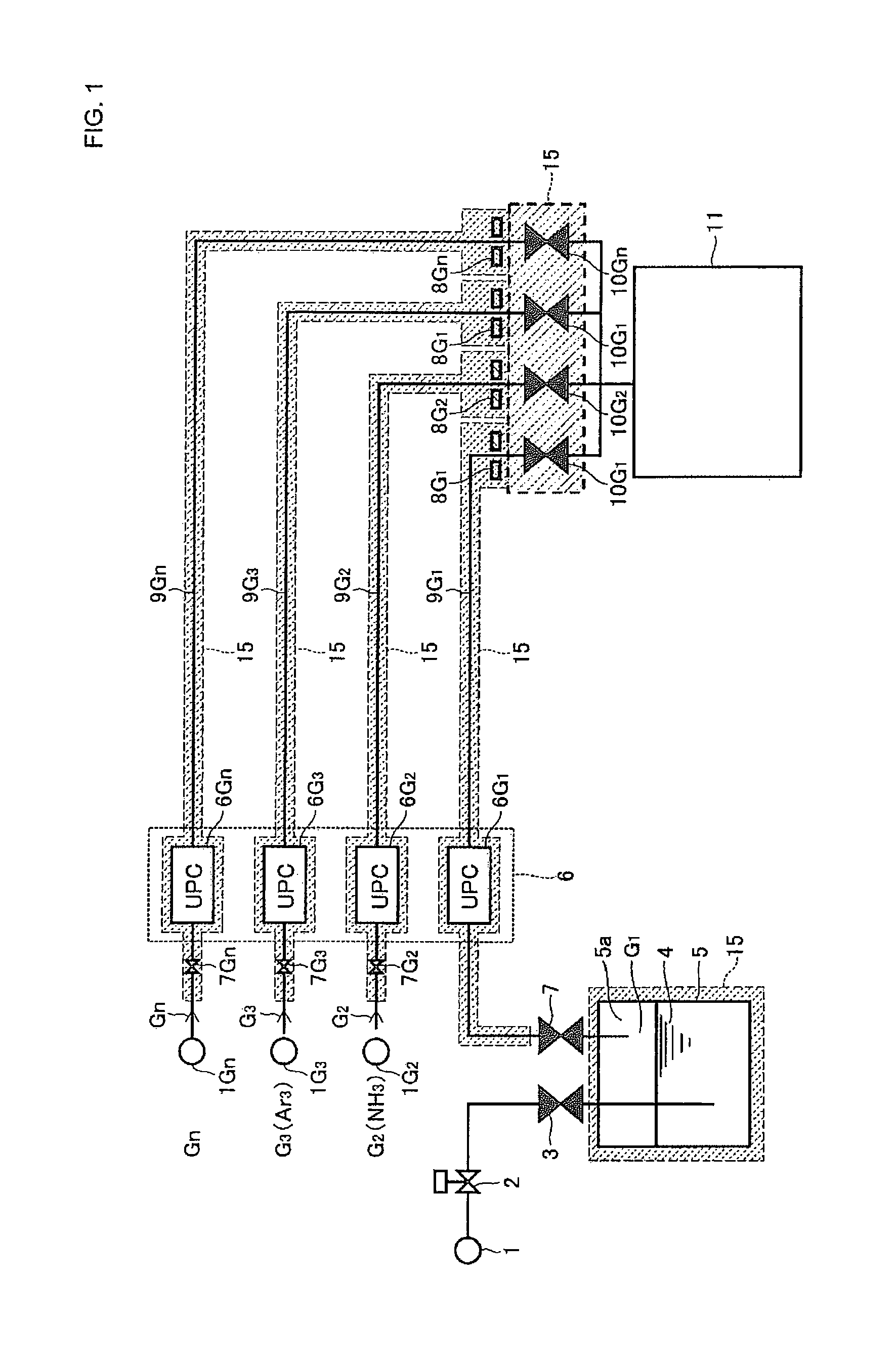

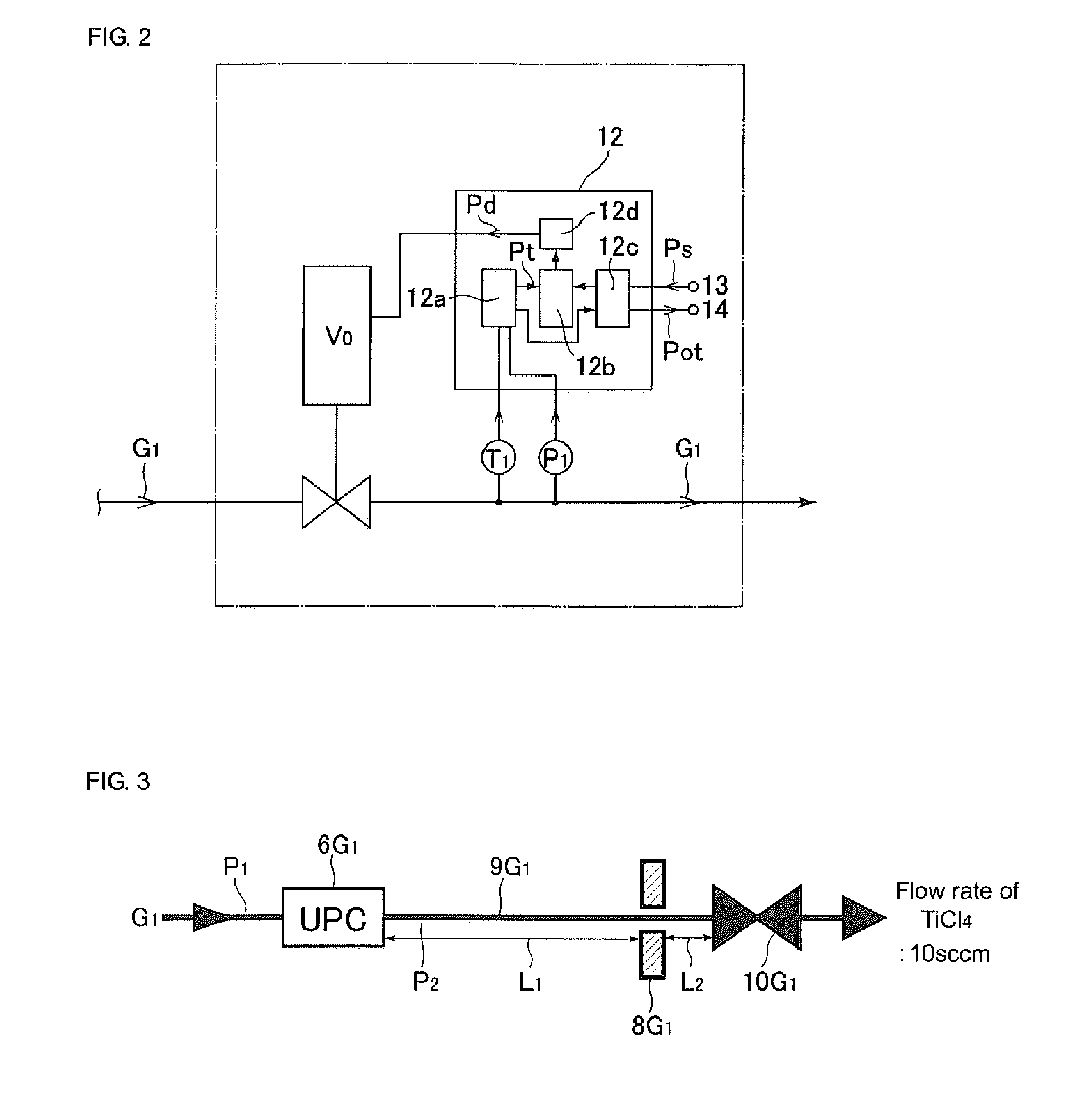

[0034]Hereinafter, an embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a systematic diagram showing a configuration of a raw material gas supply apparatus according to an embodiment of the present invention. The raw material gas supply apparatus is composed of a liquid raw material tank 1, a liquid raw material flow rate meter 2, a liquid raw material supply valve 3, a liquid raw material gas 4, a source tank 5, a raw material gas outlet valve 7, an automatic pressure regulating device 6 that controls internal pressure of distribution passages 9 for the raw material gas supplied to a process chamber 11, a throttling unit 8 (here, orifices 8G1, 8G2, 8G3 and 8Gn are used) that regulates a flow rate of supplying a gas G that is supplied to the process chamber 11, the gas distribution passages 9, supply gas switching valves 10, a constant temperature heating device 15 that heats the gas distribution passages 9, the source tank 5, and the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com