A group of compound fluorescent materials and a preparation method thereof

A technology of compound fluorescence and compounds, which is applied in the directions of luminescent materials, chemical instruments and methods, electrical components, etc., to achieve the effect of improving the luminous intensity and the ability to resist thermal decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

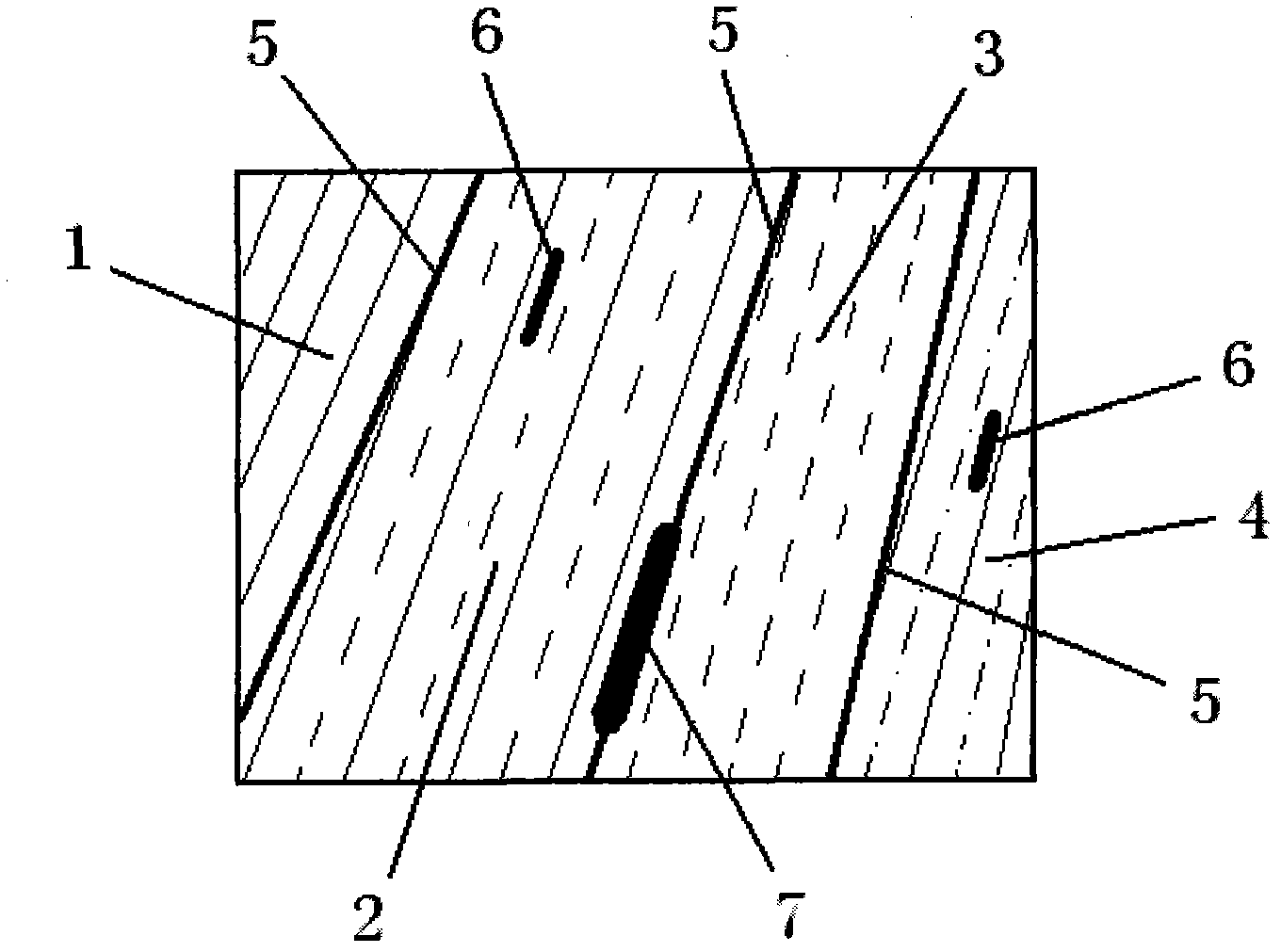

Image

Examples

Embodiment 1

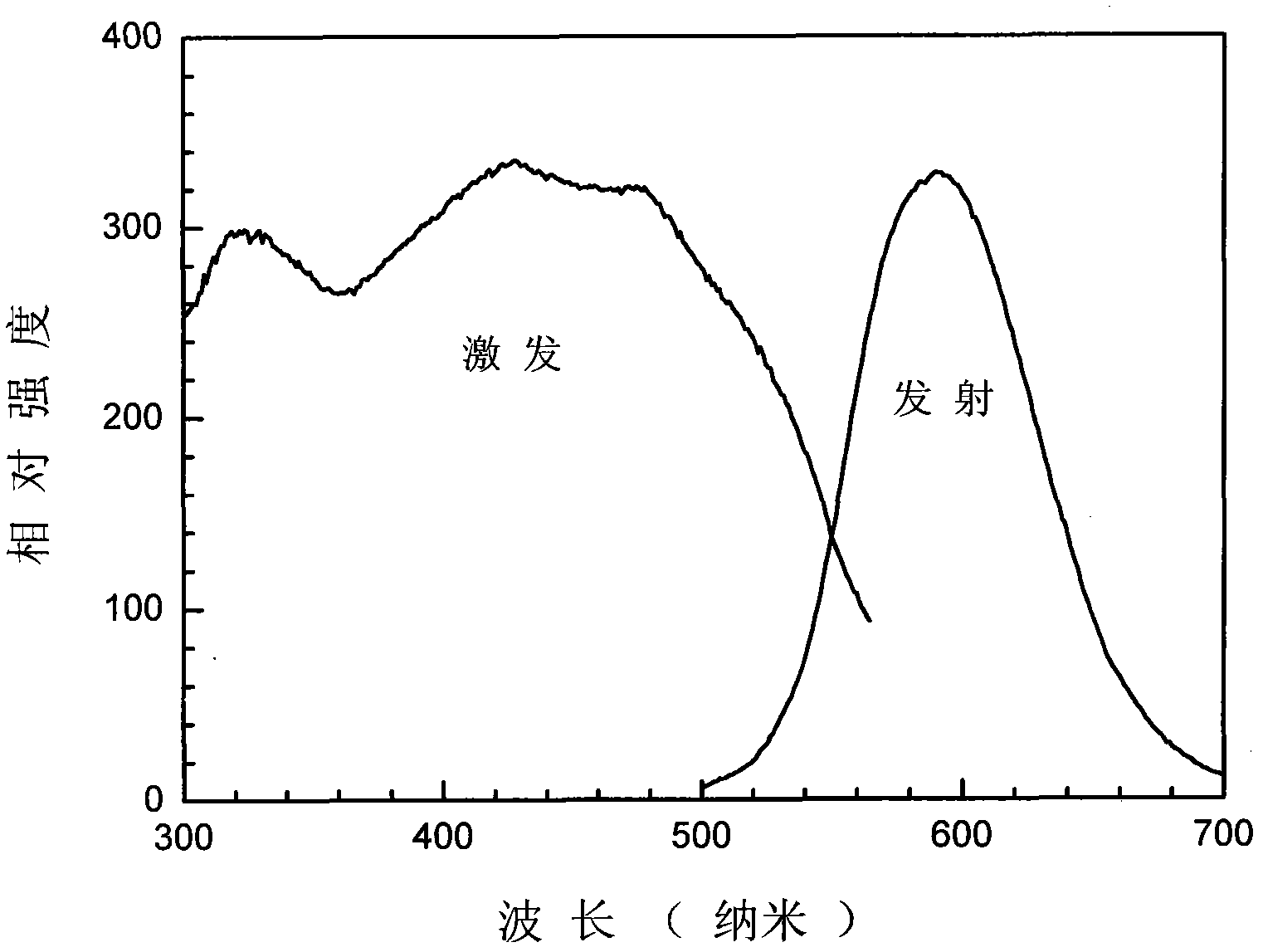

[0082] Proportion: 5SiN 1.33 o 0.06 0.99SrN 0.67 ·CaN 0.67 0.01EuN 0.67 / 0.035Au. Weigh various raw materials whose purity is analytically pure or high-purity: Si 3 N 4 15.19 g, SrCO 3 9.49 g, CaCN 2 5.20 grams, Eu 2 o 3 0.11 grams, the above raw materials are fully mixed and ground evenly, then weigh 0.45 grams of high-purity Au powder with a particle size of 10-1000nm, put it into the mixture, mix well and grind evenly, then put it into an alumina crucible, put Into the pressure heat treatment furnace, in high-purity N 2 and H 2 Sintering at 1000-1800° C. for 4-8 hours under mixed atmosphere and 0-3 atmospheric pressure. The sintered powder is orange and emits orange-red light with a peak emission wavelength of 590nm. For the excitation and emission characteristics of the sample, see figure 2 .

Embodiment 2~12

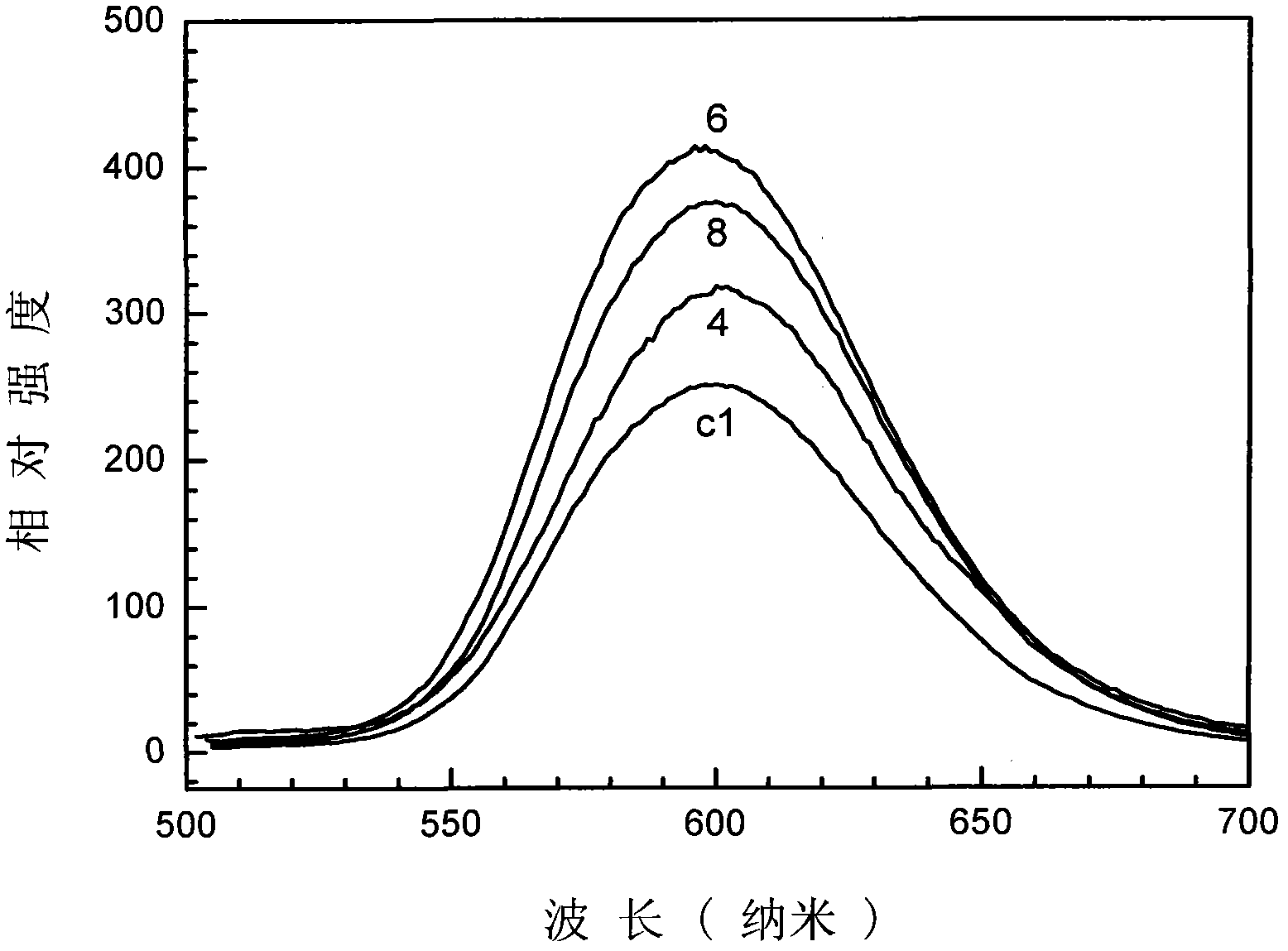

[0084] Proportion: 5SiN 1.33 o 0.07 0.95SrN 0.67 ·CaN 0.67 0.05EuN 0.67 / xAu, 0.012≤x≤0.094. Weigh the ratio as Si 3 N 4 15.15 g, SrCO 3 9.09 g, CaCN 2 5.19 g, Eu 2 o 3 Eleven parts of 0.57 grams of analytically pure or high-purity raw materials, weighing 0.15 grams, 0.23 grams, 0.3 grams, 0.38 grams, 0.45 grams, 0.53 grams, 0.6 grams, and 0.75 grams of high-purity Au powders with a particle size of 10-1000 nm gram, 0.9 gram, 1.05 gram and 1.2 gram, and then the preparation method and steps of samples with different Au content are the same as in Example 1. The sintered powder is orange-red and emits red light. The emission characteristics and Au addition amount of each embodiment are shown in Table 1. As a control, a sample 5SiN without Au was also prepared 1.33 o 0.99 0.95SrN 0.67 ·CaN 0.67 0.05EuN 0.67 (x=0, labeled c1). The emission spectra of several typical samples in Examples 2-12 under the excitation of 460nm blue light are shown in image 3 .

[00...

Embodiment 13~23

[0090] Proportion: 5SiN 1.33 o 0.08 0.95SrN 0.67 ·CaN 0.67 0.05EuN 0.67 / xZn, 0.035≤x≤0.283. Weigh the ratio as Si 3 N 4 15.15 g, SrCO 3 9.09 g, CaCN 2 5.19 g, Eu 2 o 3 Eleven parts of 0.57 grams of analytically pure or high-purity raw materials, each of 0.15 grams, 0.23 grams, 0.3 grams, 0.38 grams, 0.45 grams, 0.53 grams, 0.6 grams, and 0.75 grams of high-purity Zn powder with a particle size of 10-1000 nm was weighed. gram, 0.9 gram, 1.05 gram and 1.2 gram, and then the preparation method and steps of samples with different Zn content are the same as in Example 1. The sintered powder is orange-red and emits red light. See Table 2 for the emission characteristics of each embodiment and the amount of Zn added. Also take the sample 5SiN without Zn 1.33 o 0.09 0.95SrN 0.67 ·CaN 0.67 0.05EuN 0.67 (c1) served as a control. The emission spectra of several typical samples in Examples 13-23 under the excitation of 460nm blue light are shown in Figure 4 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com