Preparation method for titanium-aluminum alloy superfine powder

A technology of titanium-aluminum alloy and ultrafine powder, which is applied in the field of preparation of titanium-aluminum alloy ultrafine powder, which can solve the problems of complex process, small diameter ultrafine powder, difficulty in preparing purity, etc., and achieve the effect of uniform particle size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method is as follows,

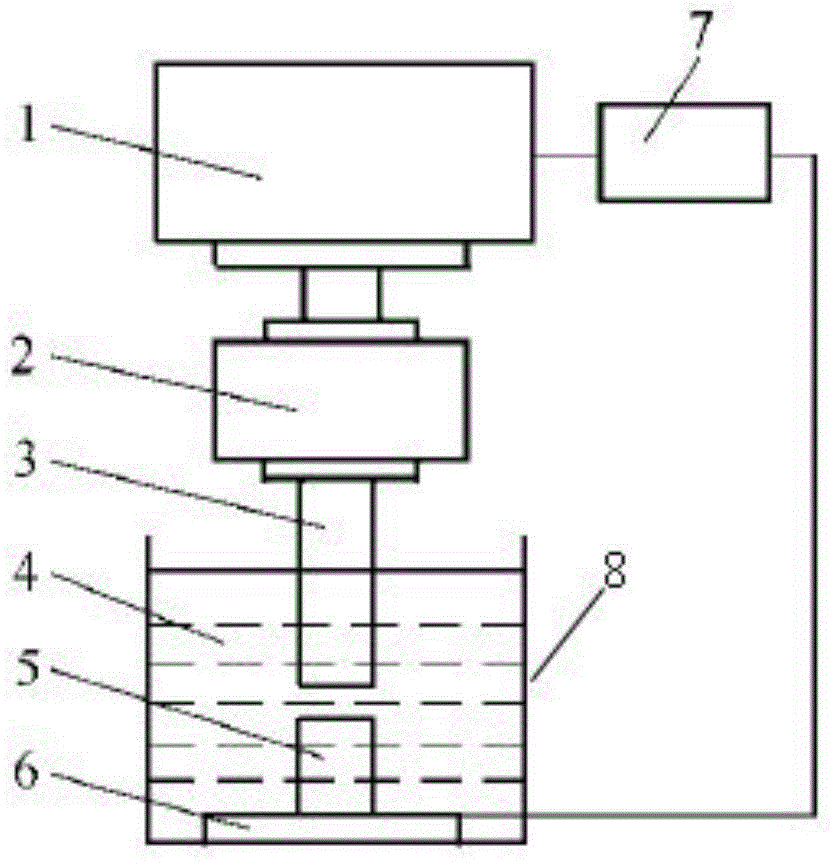

[0019] (1) Take two titanium-aluminum alloy rods with a length of 175mm and a diameter of 3mm. The composition of the titanium-aluminum alloy rods is given by atomic ratio, which is 45.8% titanium, 46.2% aluminum, and 8% tantalum. Then use sandpaper to polish and remove the scale, and then clamp them to the upper pole electrode 2 and the lower pole electrode 6 of the electric discharge pulse machining machine tool respectively.

[0020] (2) Turn on the power of the EDM machine tool, fix the lower electrode 6 on the bottom of the heat preservation barrel 8, adjust the position of the upper electrode 3 and the lower electrode 5, align one end of them, and adjust the distance between the two electrodes to a suitable The distance between the two electrodes is adjusted here to be 5mm.

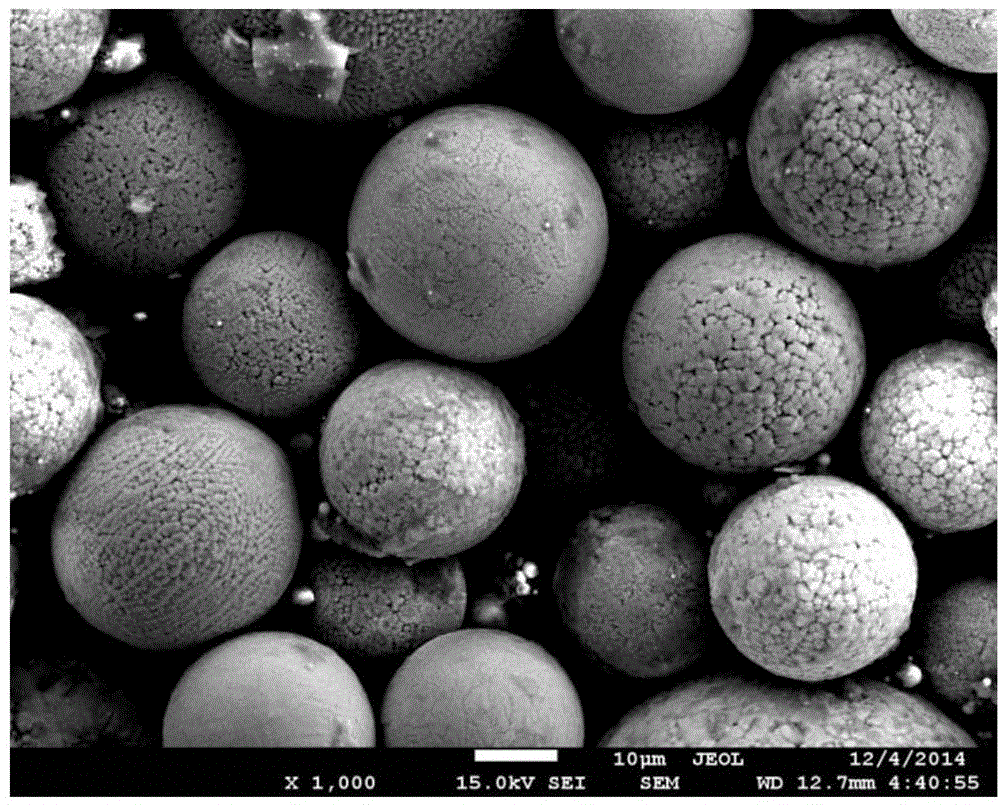

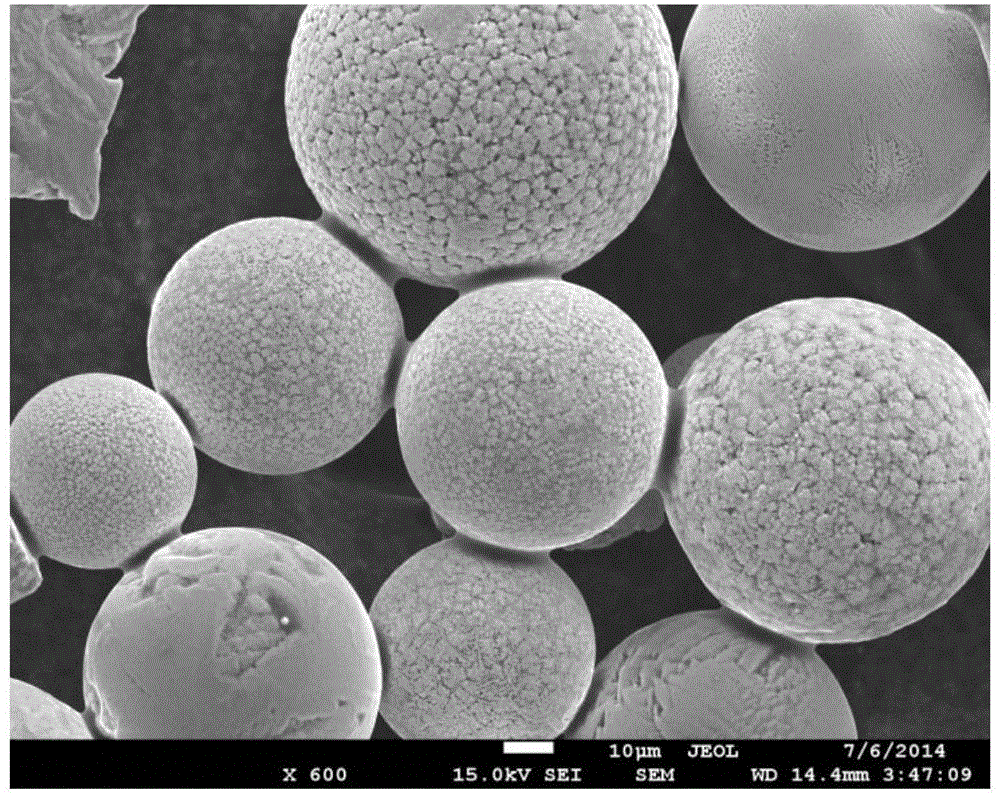

[0021] (3) Adjust the pulse width of the EDM machine tool to 200us, adjust the pulse interval of the EDM machine tool to 100us, stabilize the working ...

Embodiment 2

[0028] The preparation method is as follows,

[0029] (1) Take two titanium-aluminum alloy rods with a length of 175 mm and a diameter of 6 mm. The composition of the titanium-aluminum alloy rods is given by atomic ratio, which is 45.8% titanium, 46.2% aluminum, and 8% tantalum. Then use sandpaper to polish and remove the scale, and then clamp them to the upper pole electrode 2 and the lower pole electrode 6 of the electric discharge pulse machining machine tool respectively.

[0030] (2) Turn on the power of the EDM machine tool, fix the lower electrode 6 on the bottom of the heat preservation barrel 8, adjust the position of the upper electrode 3 and the lower electrode 5, align one end of them, and adjust the distance between the two electrodes to a suitable The distance between the two electrodes is adjusted here to be 5mm.

[0031] (3) Adjust the pulse width of the EDM machine tool to 200us, adjust the pulse interval of the EDM machine tool to 100us, stabilize the workin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com