Ecological closed cycle water fish-cultivating method

A closed-loop, ecological technology, applied in fish farming, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of sedimentation, affecting fish health breeding, and high lift of valveless filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

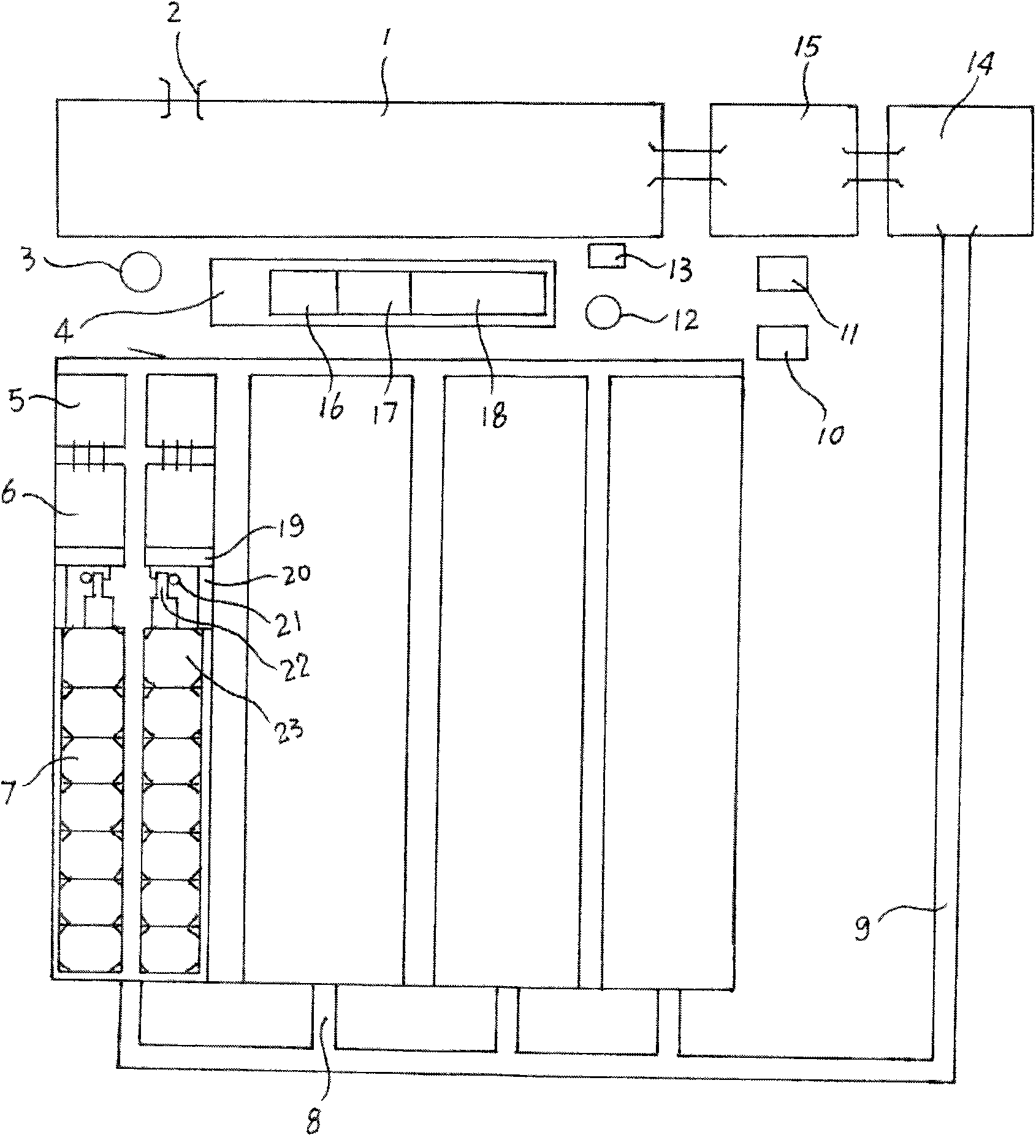

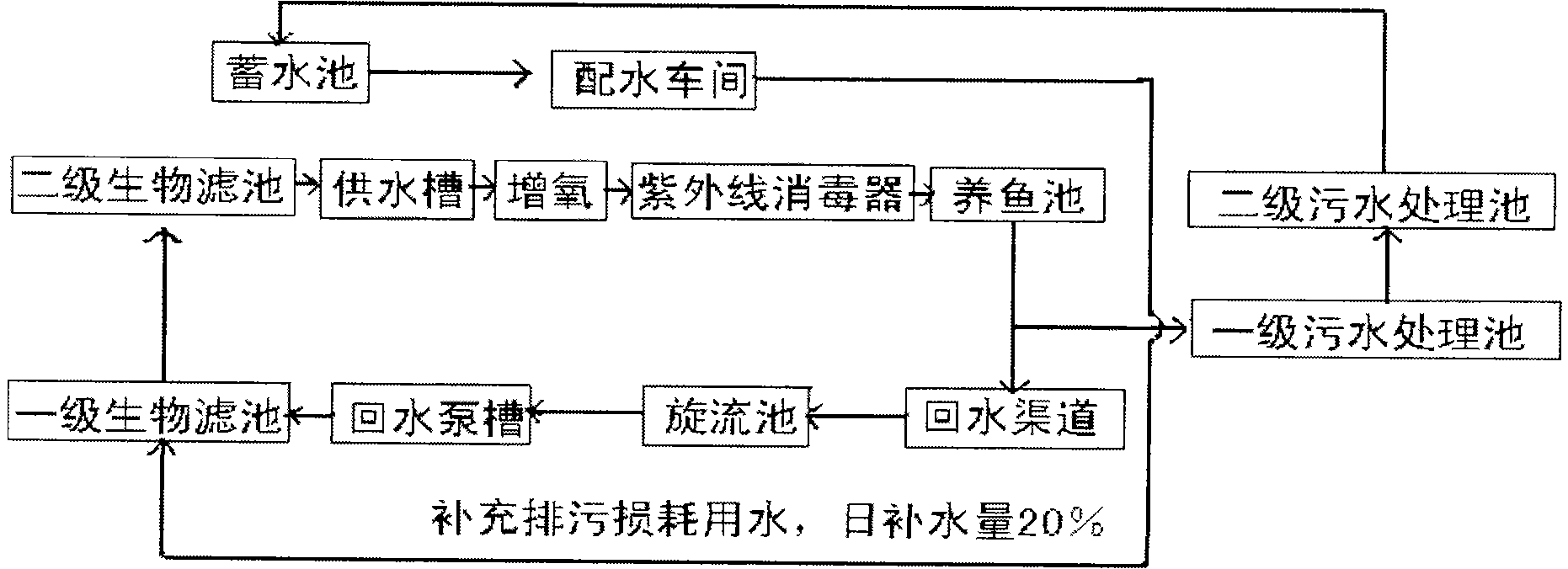

[0045] See figure 1 As shown, first, a site is selected along the coast of natural seawater with no runoff pollution, convenient transportation, sufficient agricultural power, and broadband network information conditions, and a water storage and sedimentation tank 1 is built, and a sluice 2 is provided in the corresponding seawater direction. The general pool specification is 20000m 2 above. Water storage sedimentation tank 1 is dug deep as far as possible, reaches the degree of receiving water at high tide, reduces power water storage, saves electric power. If the soil quality of the storage and sedimentation tank 1 is too soft, slope protection shall be provided to avoid muddy water due to the impact of wind and waves. The water holding depth of the water storage sedimentation tank 1 should be more than 2m, which is conducive to maintaining stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com