Ecological closed cycle water fish-cultivating method

A closed cycle, ecological technology, applied in fish farming, chemical instruments and methods, biological water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

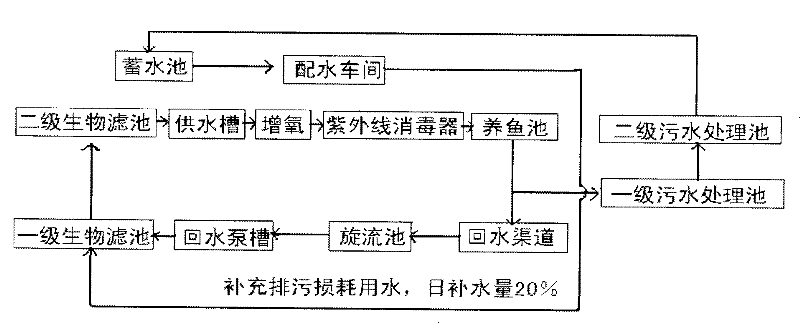

Method used

Image

Examples

Embodiment Construction

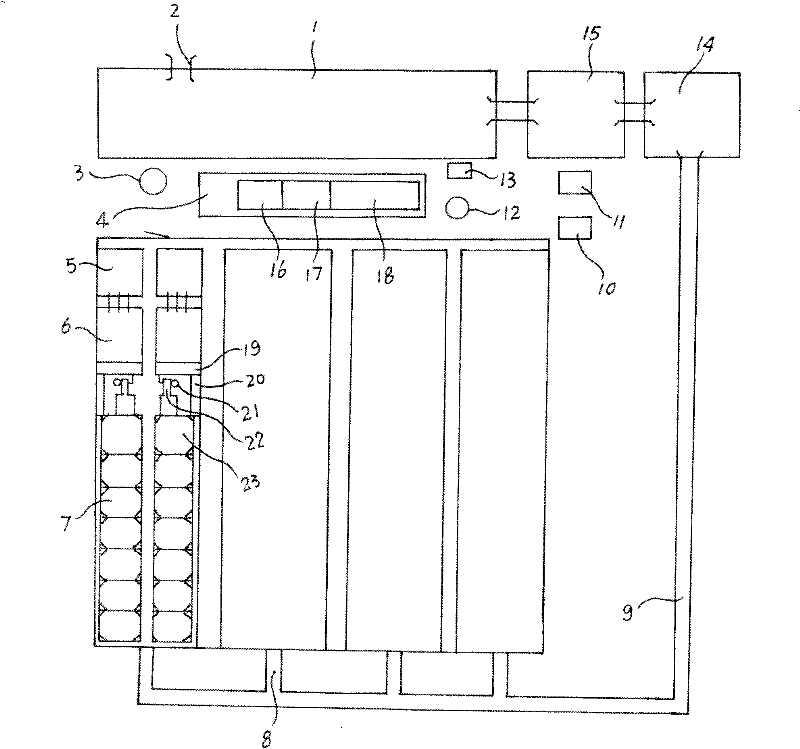

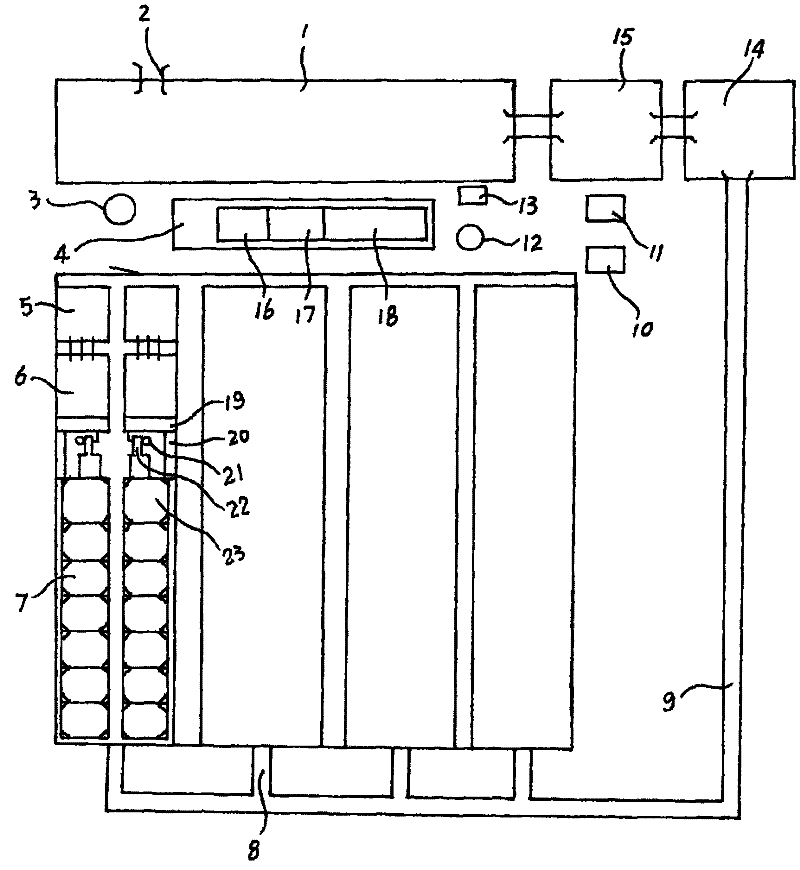

[0047] Primary biofilter 5. The specifications of the biological filter are 6m long x 6m wide x 3m deep. The filter bed is mainly made of sand and gravel, and the thickness of the fine sand layer is 300mm. Below is the pebble, the thickness of the pebble is 200mm, the beam supporting the pebble is a reinforced concrete structure, 120mm×120mm×3000mm, and then the beam is supported by the longitudinal beam, the distance between the beams is 100mm, the distance between the beams is filled with pebbles, and a layer of round hole plastic is laid on the bottom of the pebble. Expanded mesh to prevent pebbles from leaking out. Install backwash sewage pipes on both sides of the pool wall at a distance of 100mm from the sand layer surface, with a diameter of 110mm, controlled by intubation or valves, and the backwash sewage enters the sewage ditch through the sewage pipe. The ratio of the area of the primary biofilter to the total area of the fish pond is 1:7-10, and the boundary w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com