Method for recovery and cascade utilization of waste heat of supercritical water treatment system of waste organic substances

A technology of supercritical water and treatment system, which is applied in the direction of solid waste removal, heating water/sewage treatment, oxidized water/sewage treatment, etc., to reduce the loss of heat exchange temperature difference and improve the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

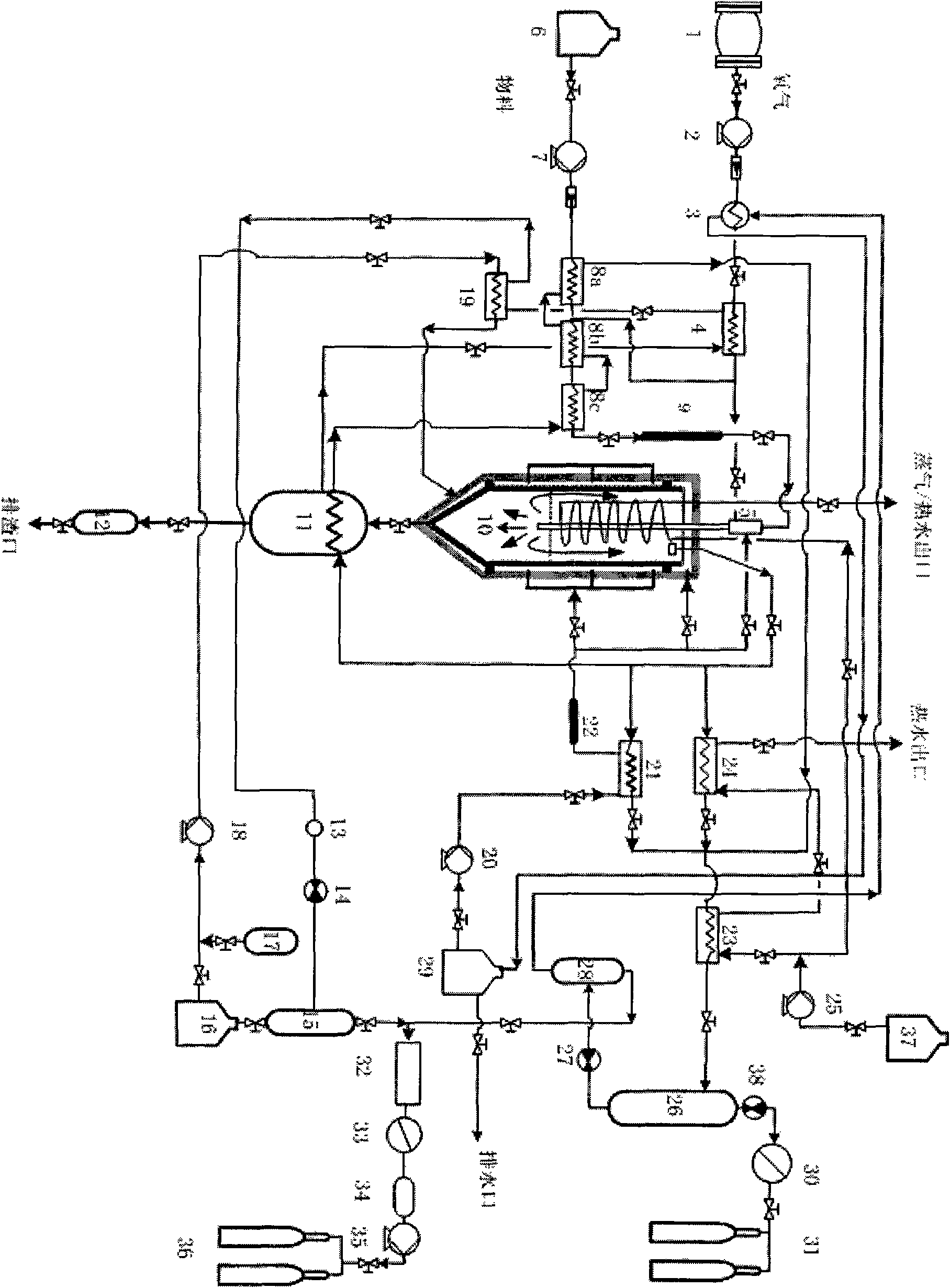

[0029] The waste heat recovery and cascade utilization method of the waste organic supercritical water treatment system of the present invention is based on the waste organic supercritical water treatment system. The supercritical water treatment system for waste organic matter mainly includes: a reaction unit, an oxygen supply unit, a material supply unit, a gas collection unit, a first evaporation wall water supply unit, a second evaporation wall water supply unit, and a heat energy utilization unit .

[0030] The reaction unit includes a vertically arranged mixer 5 , a countercurrent tank reactor 10 with a built-in evaporation wall, a desalination and slag removal device 11 with a built-in heating coil, and a salt storage tank 12 . The material outlet port of the mixer 5 is connected to the material inlet port of the reactor 10, the salt discharge outlet port at the bottom of the reactor 10 is connected to the inlet port of the desalination and slagging device 11, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com