Liquid oxygen container with multi-layer vacuum thermal insulation layer and fiber reinforced composite material layer

A composite material layer, fiber-reinforced technology, applied in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problems of excessive weight, low storage and transportation efficiency, and high storage and transportation costs. The effect of high pressure, light weight and improved storage and transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

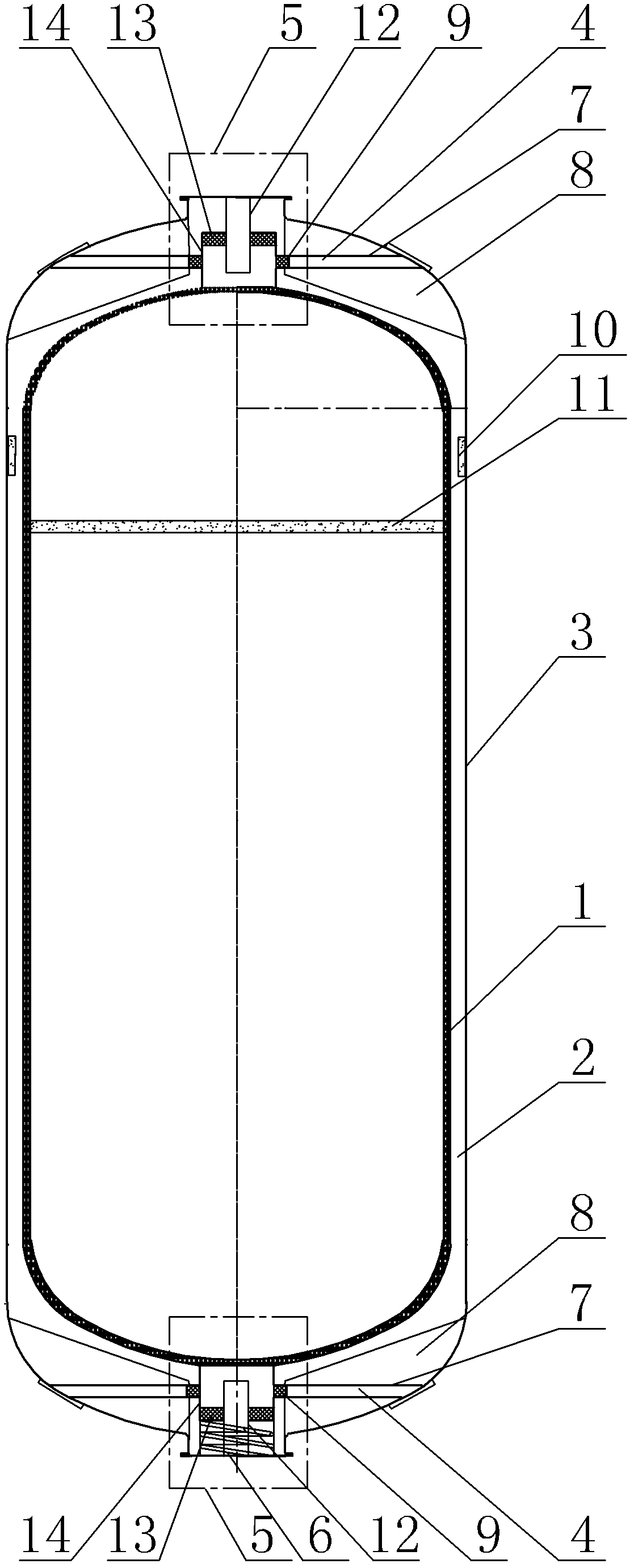

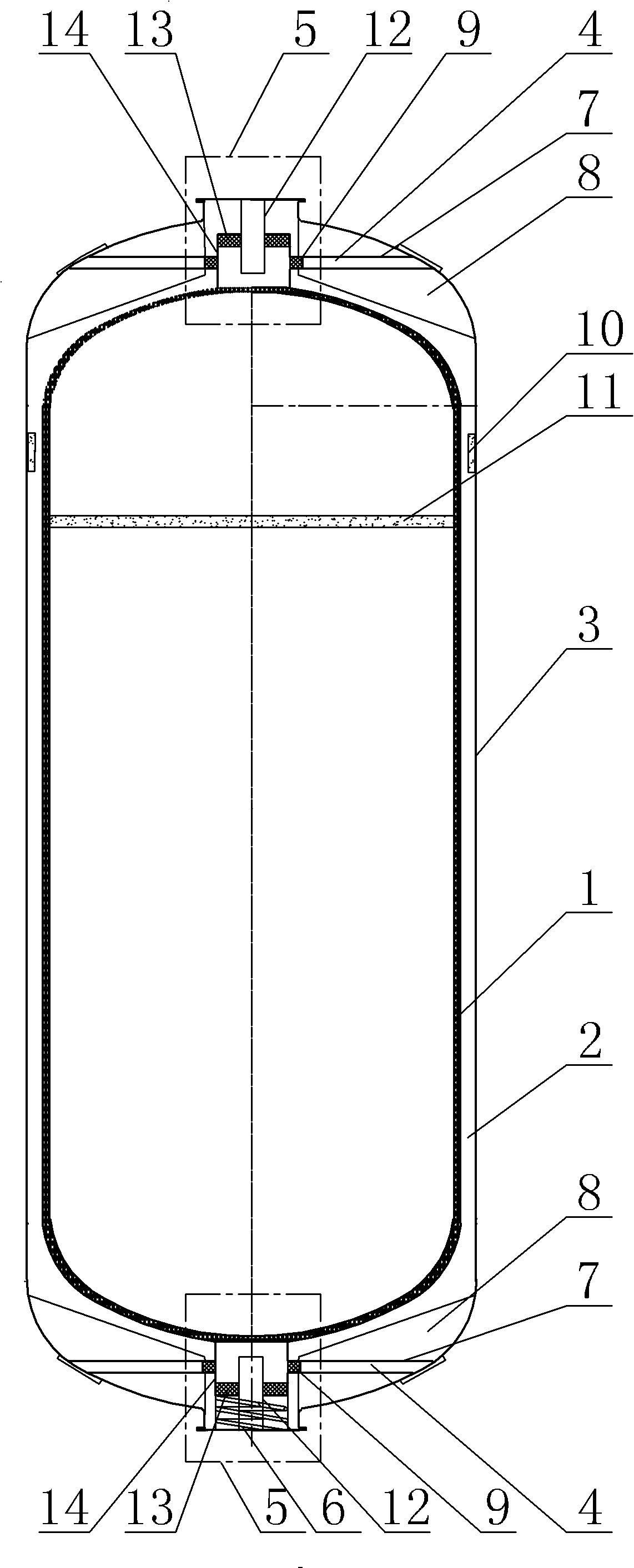

[0011] Specific implementation mode 1: Combination Figure 1~2 Explain that the liquid oxygen container with multiple vacuum insulation layers and fiber-reinforced composite material layers of this embodiment includes an inner container 1, a container shell 3, two axial support members 5 and a spiral tube 6, and the inner container 1 passes Two axial support members 5 are installed in the container shell 3. A vacuum chamber 2 is formed between the inner container 1 and the container shell 3. Each axial support member 5 consists of a support shaft 12, a first support plate 13, and a support circle. The inner walls of the two ends of the container shell 3 are each fixed with a supporting shaft 12, the two supporting shafts 12 are arranged coaxially with the axis of the container shell 3, and each supporting shaft 12 is fixedly sleeved with a first supporting plate 13 , A support cylinder 14 is fixedly mounted on the outer wall at both ends of the inner liner 1, and the two support...

specific Embodiment approach 2

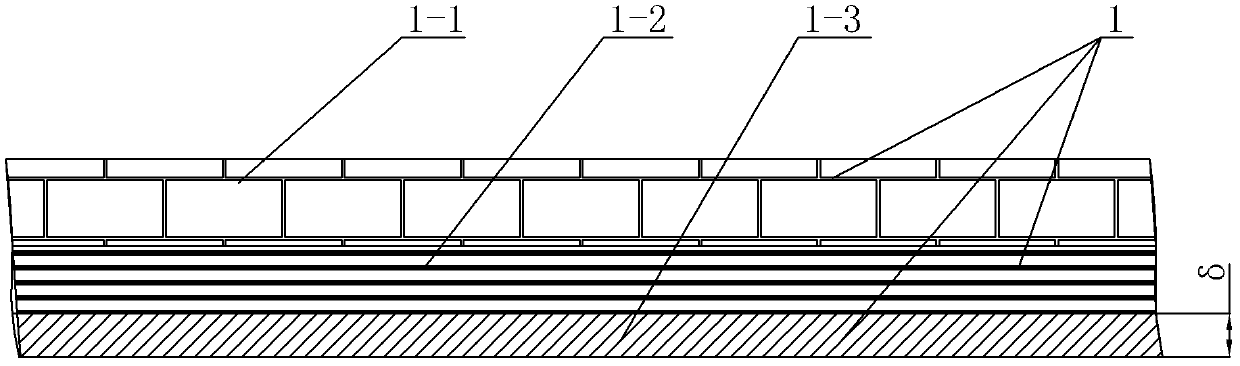

[0012] Embodiment 2: The metal lining layer 1-1 of this embodiment is made of aluminum alloy, and the ratio of the tensile yield strength to the elastic modulus of the aluminum alloy is F TY / E is at least 0.2%, and the elongation at break of the aluminum alloy is at least 11%. Such a design can meet the requirement of repeated use under low temperature conditions, and meet the requirement of repeated use for multiple times of aluminum alloy lining without being damaged due to low temperature becoming brittle. The other composition and connection relationship are the same as in the first embodiment. Specific implementation mode three: combination figure 2 Note that the thickness δ of the metal lining layer 1-1 in this embodiment is 0.5 mm to 8.0 mm. Such a design makes it easier to process thin aluminum alloy linings, thereby greatly reducing weight. The other composition and connection relationship are the same as those in the first or second embodiment. Specific embodime...

specific Embodiment approach 5

[0013] Embodiment 5: The liquid oxygen container in this embodiment further includes a normal temperature gas adsorbent 10, and the normal temperature gas adsorbent 10 is disposed on the inner wall of the container shell 3. Such a setting ensures that the outer layer of the vacuum chamber 2 is in a normal temperature environment during use, and small molecules are fully absorbed by the warm gas adsorbent, and the vacuum degree required in the vacuum chamber 2 is ensured. The other composition and connection relationship are the same as those in the first, second or fourth embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com