High-temperature proton exchange compound film

A proton exchange and composite membrane technology, applied in the field of composite membranes, can solve the problems of non-continuous production, time-consuming, high strength, etc., and achieve the effects of reducing internal resistance, increasing electrical conductivity, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

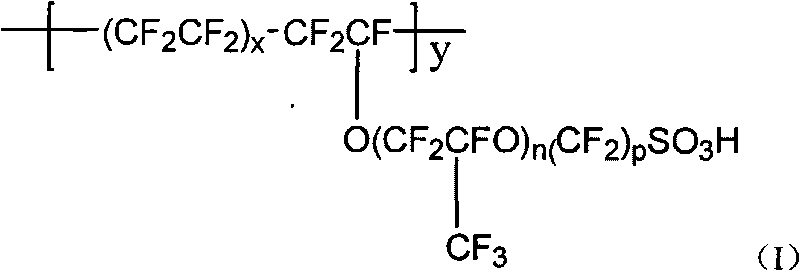

[0042]Get a 5-micron polytetrafluoroethylene membrane (80% porosity, 0.5-3 microns in aperture) and immerse in 5% perfluorosulfonic acid resin propanol-water solution, wherein the structural formula of perfluorosulfonic acid resin is

[0043]

[0044] n=1, p=2, ion exchange capacity 0.97mmol / g, molecular weight 190,000.

[0045] Then, the wet film sample was dried in an oven at 140° C. for 30 seconds. In order to completely block the pores in the membrane, this process step can be repeated more than 2 times. Finally, the composite membrane was treated at 190° C. for 30 minutes to obtain a composite membrane with a thickness of 8 μm, and then boiled in 5% sulfuric acid for 30 minutes under normal pressure to obtain a 5 μm composite membrane.

Embodiment 2

[0047] Take a 10-micron thick biaxially stretched polytetrafluoroethylene film (89% porosity, 0.2-2 micron diameter), and fix it on a flat plate. A 15% perfluorosulfonic acid resin isopropanol-water solution is coated on one side of the polytetrafluoroethylene membrane, so that the perfluorosulfonic acid resin solution completely fills the pore volume in the membrane, so that all pores are completely blocked. Wherein the structural formula of perfluorosulfonic acid resin is

[0048]

[0049] n=1, p=2, ion exchange capacity 1.05mmol / g molecular weight 210,000.

[0050] The coated film samples were dried in a drying oven at 100° C. for 15 minutes. In order to completely block the pores in the membrane, the coating and drying process can be repeated more than 2 times. Then the drying temperature was raised to 210° C. and dried for 5 minutes. Then boil in 5% sulfuric acid under normal pressure for 60 minutes to obtain a 12-micron composite membrane.

Embodiment 3

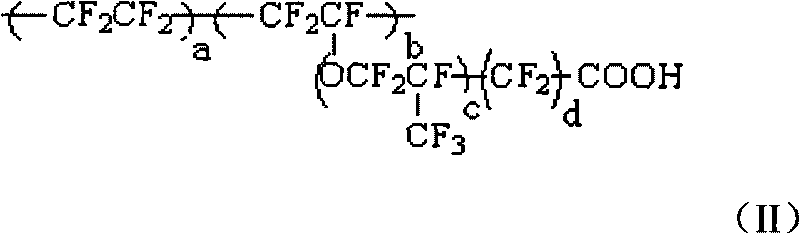

[0052] An 8-micron thick biaxially stretched polyvinylidene fluoride film (porosity 75%, pore diameter 5 microns) was fixed on a flat plate. 24% perfluorosulfonic acid resin isopropanol-propanol-water solution is coated on both sides of the polyvinylidene fluoride film by screen printing, wherein the structural formula of perfluorosulfonic acid resin is

[0053]

[0054] n=0, p=2, ion exchange capacity 1.35mmol / g, molecular weight 240,000.

[0055] The film was then dried in an oven at 160° C. for 40 minutes. Then, the dried film after drying was taken out and boiled in distilled water for 30 minutes to swell the film to obtain a 10 micron composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com