Production method for heat-insulation noise-insulation water-proofing material

A technology of waterproof material and manufacturing method, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of high manufacturing cost, unsatisfactory cost, small volume, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

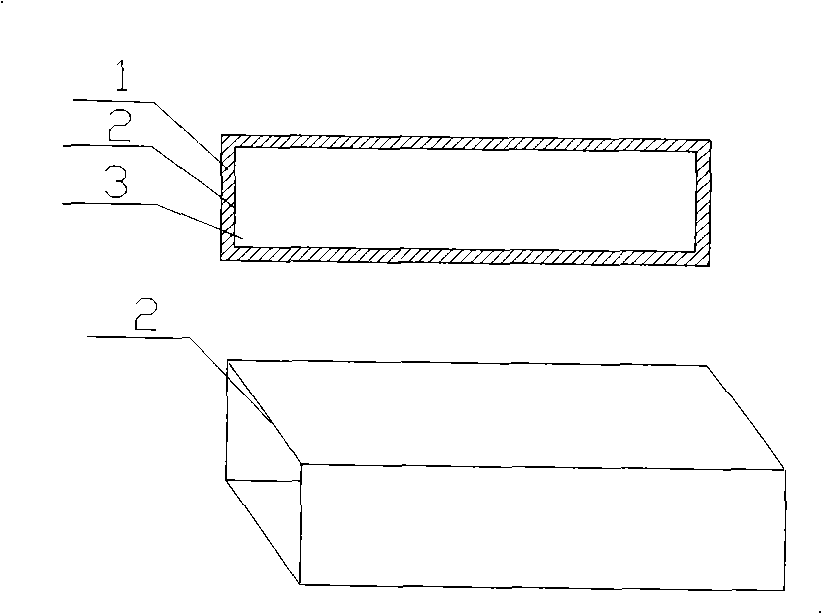

[0020] One is to make a rectangular skeleton with materials such as steel or aluminum or plastic or wood or straw composite materials. The second is to use polymer materials such as thermoplastic polyester, polychlorotrifluoroethylene, polyvinyl fluoride, chlorinated polyether, etc. to make a polymer film or use a thin plate made of other materials to wrap the skeleton and seal it, and then use a vacuum machine to pump out the air. , made of vacuum or sub-vacuum sheet. It can also be made into a vacuum or sub-vacuum sheet in a vacuum or sub-vacuum state. After sealing, if there is no need to evacuate or sub-vacuum, it can be made into a sealed hollow plate.

[0021] The thickness of the thin film sheet can be set according to the need, the thickness of the plate can be set according to the heat preservation needs, and the thickness of the skeleton can be set, the area of the plate can be set according to the need, if the plate needs to be deformed, the deformation of the sk...

Embodiment 2

[0023] The technical scheme of the present invention to manufacture clothing fabrics, one is to process the polymer film into a granular shape like table tennis rubber; The grid should ensure the formation of an independent smaller vacuum or sub-vacuum space. Fourth, it is pasted and sealed in a vacuum or sub-vacuum environment to form a vacuum or sub-vacuum clothing fabric to form an independent smaller vacuum space. When it is damaged, it will not affect the thermal insulation effect of the whole vacuum layer. Each particle actually plays the role of a skeleton. If it is processed in an ordinary environment to reduce particles or make other simple improvements, it can be made into a hollow airtight clothing fabric, which also has good performance. thermal insulation performance. Compared with the heat-preserving clothing manufactured by the prior art, the heat-preserving effect is good and the cost is low. People no longer feel swollen in severe cold, and the quilts and bed ...

Embodiment 3

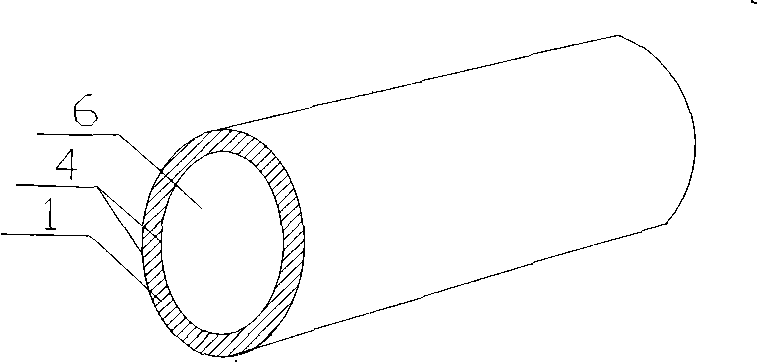

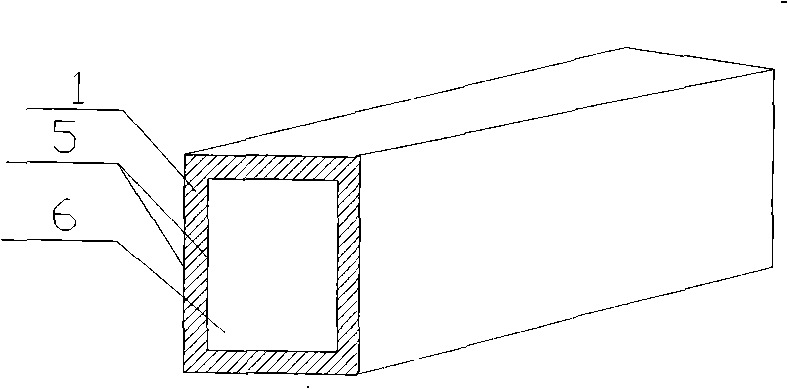

[0025] Put two kinds of radii of polymer film or thin-walled pipes into a pipe along the circular skeleton to make a circular skeleton. The thickness of the skeleton is equal to the difference between the two radii pipes, or no skeleton is needed at all, and the air is drawn out after sealing the pipe , the tube wall forms a vacuum or sub-vacuum environment, and the skeleton is in a vacuum or sub-vacuum environment to manufacture a vacuum or sub-vacuum tube. The amount of skeleton of the vacuum or sub-vacuum pipe can be set according to the needs, and it can also be made into a rectangle to make a vacuum or sub-vacuum rectangular pipe or make the skeleton into other shapes to obtain a special-shaped vacuum or sub-vacuum pipe. A piece of linear steel or linear plastic can also be wound into an equicircular spiral, covered with two diameters of polymer films or thin-walled pipes, sealed and pumped out air to make vacuum or sub-vacuum pipes, if it is not necessary to pump out air,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com