Environmental stress-resistant epoxy resin powder coating and preparation method thereof

An epoxy resin powder and environmental stress technology, applied in epoxy resin coatings, powder coatings, anti-corrosion coatings, etc., can solve the problems of general anti-environmental stress performance, low curing cross-linking density, easy chain breaking and degradation, etc., to achieve Improvement of mechanical strength, improvement of heat resistance, enhancement of toughness and effects of glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

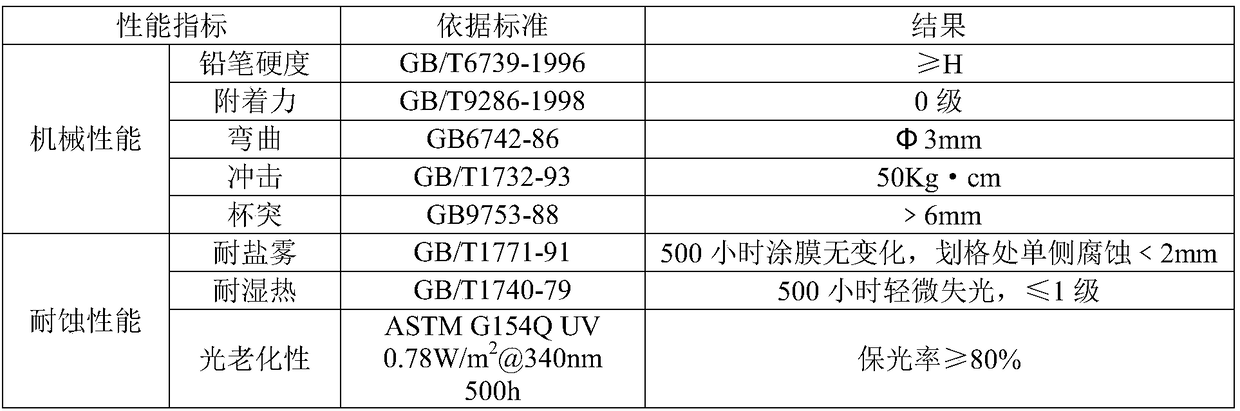

Image

Examples

Embodiment 1

[0029]An epoxy resin powder coating resistant to environmental stress, made of the following components: 72g of epoxy resin, 13g of high-density polyethylene resin, 8g of polybismaleimide resin, 12g of hydroxyl silicone oil, and 20g of silane crosslinking agent , Salicylic acid 5g, organic solvent 180g, antioxidant 1.6g, light shielding agent 1.4g, leveling agent 2.2g, defoamer 2.6g, toughening agent 8g, filler 8g, curing agent 2g, polyvinylidene fluoride 28g , ABS monomer composition 18g, initiator 1.6g and water 180g, wherein in the ABS monomer composition of mass fraction 100wt%, acrylonitrile is 25wt%, butadiene is 20wt%, and the remainder is styrene, silane The crosslinking agent is vinyltriethoxysilane; the filler is a composition of andalusite powder, fluorite powder and kaolin powder, and the mass ratio of the three is 1:0.7:0.45; the organic solvent is an aqueous solution of acetone with a mass concentration of 65 wt%. ; The toughening agent is lignin powder.

[0030...

Embodiment 2

[0036] An epoxy resin powder coating against environmental stress, made of the following components: 65g of epoxy resin, 11g of high-density polyethylene resin, 7g of polybismaleimide resin, 10g of hydroxyl silicone oil, and 18g of silane crosslinking agent , Salicylic acid 3g, organic solvent 160g, antioxidant 1g, light shielding agent 0.8g, leveling agent 1.5g, defoamer 2g, toughening agent 6g, filler 6g, curing agent 1g, polyhexafluoropropylene 26g, ABS 13g of monomer composition, 1g of initiator and 120g of water, wherein, in the ABS monomer composition based on mass fraction 100wt%, acrylonitrile is 20wt%, butadiene is 35wt%, and the rest is styrene; silane crosslinking The agent is vinyltrimethoxysilane; the filler is a composition of andalusite powder, fluorite powder and kaolin powder, and the mass ratio of the three is sequentially 1:0.6:0.4; the organic solvent is an aqueous solution of acetone with a mass concentration of 60wt%; the toughening The agent is lignin po...

Embodiment 3

[0043] An epoxy resin powder coating resistant to environmental stress, made of the following components: 85g of epoxy resin, 15g of high-density polyethylene resin, 10g of polybismaleimide resin, 14g of hydroxyl silicone oil, and 23g of silane crosslinking agent , salicylic acid 7g, organic solvent 200g, antioxidant 2g, light shielding agent 1.7g, leveling agent 3g, defoamer 3g, toughening agent 10g, filler 10g, curing agent 4g, polyhexafluoropropylene or polytrifluoroethylene Vinyl chloride 32g, ABS monomer composition 20g, initiator 2g and water 200g, wherein, in the ABS monomer composition of mass fraction 100wt%, acrylonitrile is 30wt%, butadiene is 15wt%, and the rest is benzene Ethylene; silane crosslinking agent is vinyl tris (methoxyethoxy) silane; filler is the composition of andalusite powder, fluorite powder and kaolin powder, the mass ratio of the three is 1:0.8:0.5 in turn; organic solvent It is an aqueous solution of acetone with a mass concentration of 70 wt%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com