Preparation method of high-temperature resistant and high-transparent polychlorotrifluoroethylene

The technology of polychlorotrifluoroethylene and chlorotrifluoroethylene is applied in the field of preparation of polychlorotrifluoroethylene, which can solve the problems of yellowing, degradation, and brown color of polychlorotrifluoroethylene, and achieve the effect of excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

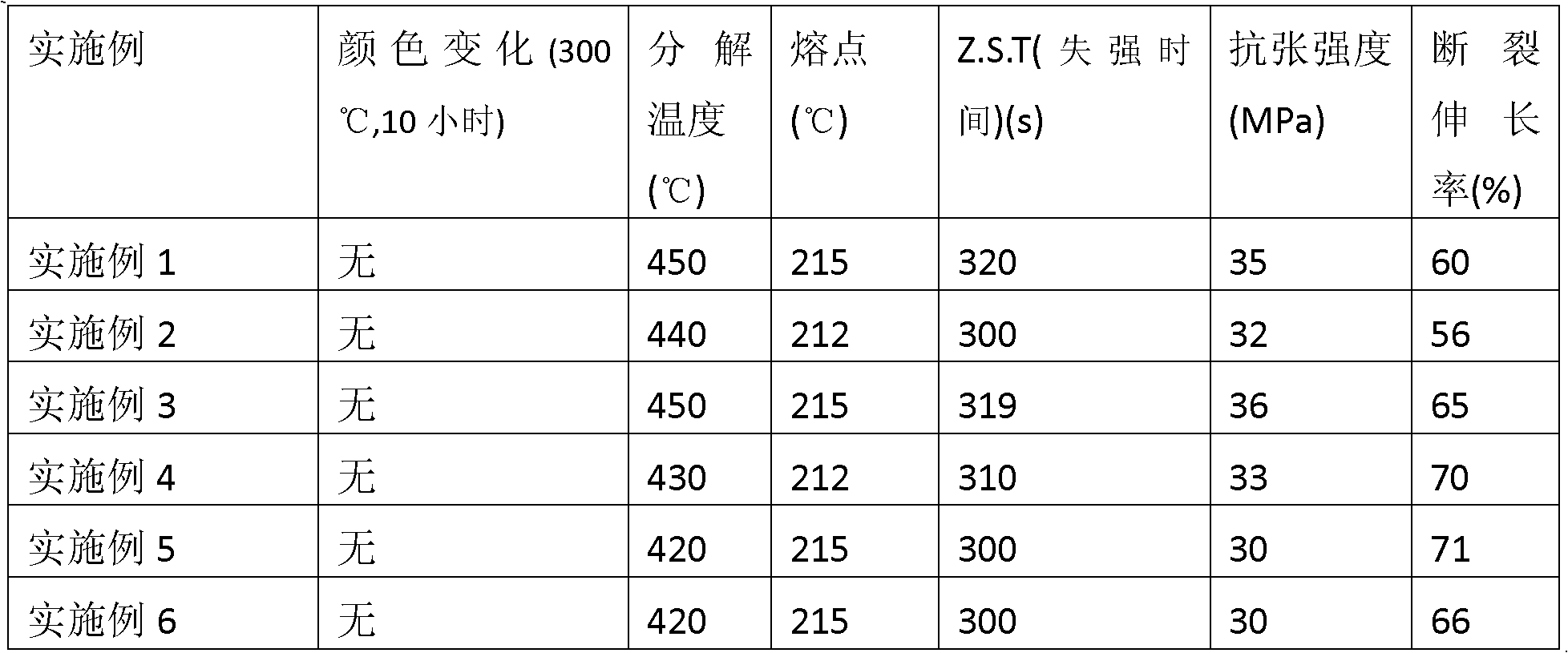

Examples

Embodiment 1

[0019] Put 40 kg of deionized water with a conductivity of 0.02 into a 50L 304SS stainless steel jacketed and stirred autoclave, then add 8 kg of chlorotrifluoroethylene monomer into the polymerization kettle, start the stirring device, and pass people through the jacket. Low-pressure steam, control the temperature in the polymerization tank to 58°C, and the pressure in the polymerization tank to 0.69Mpa. When the temperature of the polymerization system reaches 58°C, pump 4 grams of azobisisooctanonitrile with a metering pump, then keep the system temperature at 58°C, and the system pressure at 0.69Mpa for 12 hours, drain the system pressure, and the polychlorotrifluoroethylene powder and water are emitted from the bottom of the polymerization kettle, and the polychlorotrifluoroethylene powder and water are separated by a plate filter, and the polytrifluorochloroethylene powder is dried in an oven to obtain 6 kg of dry polytrifluorochloroethylene powder.

[0020] Add 6 kg of ...

Embodiment 2

[0023] Put 35 kg of deionized water with a conductivity of 0.06μ into a 50L 304SS stainless steel jacketed and stirred autoclave, then add 5 kg of chlorotrifluoroethylene monomer into the polymerization kettle, start the stirring device, and pass Use low-pressure steam to control the temperature in the polymerization kettle to 70°C and the pressure in the polymerization kettle to 0.9Mpa. When the temperature of the polymerization system reaches 70°C, pump 5 grams of azobisisononononitrile with a metering pump, then keep the system temperature at 70°C and the system pressure at 0.9Mpa for 13 hours, drain the system pressure, and the polychlorotrifluoroethylene powder and water are discharged from the bottom of the polymerization kettle, and the polychlorotrifluoroethylene powder and water are separated by a plate filter, and the polytrifluorochloroethylene powder is dried in an oven to obtain 4 kg of polytrifluorochloroethylene dry powder.

[0024] Add 4 kg of polychlorotrifluo...

Embodiment 3

[0027] Put 40 kg of deionized water with a conductivity of 0.08μ into a 50L 304SS stainless steel jacketed and stirred autoclave, then add 5 kg of chlorotrifluoroethylene monomer into the polymerization kettle, start the stirring device, and pass Use low-pressure steam to control the temperature in the polymerization kettle to 58°C and the pressure in the polymerization kettle to 0.69Mpa. When the temperature of the polymerization system reaches 58°C, pump 4 grams of azobisisodecylnitrile with a metering pump, then keep the system temperature at 58°C, and the system pressure at 0.69Mpa for 15 hours, drain the system pressure, and the polychlorotrifluoroethylene powder and water are released from the bottom of the polymerization kettle, and the polychlorotrifluoroethylene powder is separated from water by a plate filter, and the polychlorotrifluoroethylene powder is dried in an oven to obtain 3.5 kg of dry polytrifluorochloroethylene powder.

[0028] Add 3.5 kg of polychlorotri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com