Cored wire with super-hydrophobic function and application of cored wire with super-hydrophobic function to preparation of coating with super-hydrophobic function

A super-hydrophobic, functional powder technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of large-area preparation of difficult-to-super-hydrophobic surfaces, limited application of super-hydrophobic surfaces, and inability to realize industrial applications, etc. Achieving good self-cleaning, excellent corrosion resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

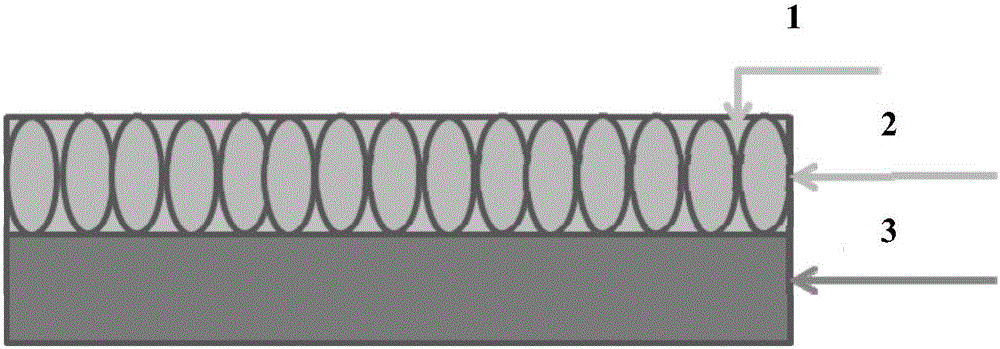

[0045] In this embodiment, the base material is 316L stainless steel, the coating has a good bonding force with the base, and the coating thickness is 250 μm. The concrete preparation method of this superhydrophobic functional coating:

[0046] (1) Preparation of powder core wire: the coat of powder core wire is 316L stainless steel, the width of the steel strip is 12 mm, and the thickness is 0.3 mm. The powder core is a mixed powder of metallic pure aluminum and polytetrafluoroethylene, wherein the size of metallic pure aluminum is 40-60 μm, PTFE powder is 12 μm, the mass ratio of metal pure aluminum to PTFE is 6:4, the diameter of powder core wire is 2mm, and the powder coating rate is 10wt.%.

[0047] (2) Coating preparation: prepared by supersonic arc spraying process, the specific spraying parameters are: current 120A, voltage 40V, compressed air pressure 0.8MPa, spraying distance 200mm, arc gun moving speed 25mm / s, spraying times 3 times .

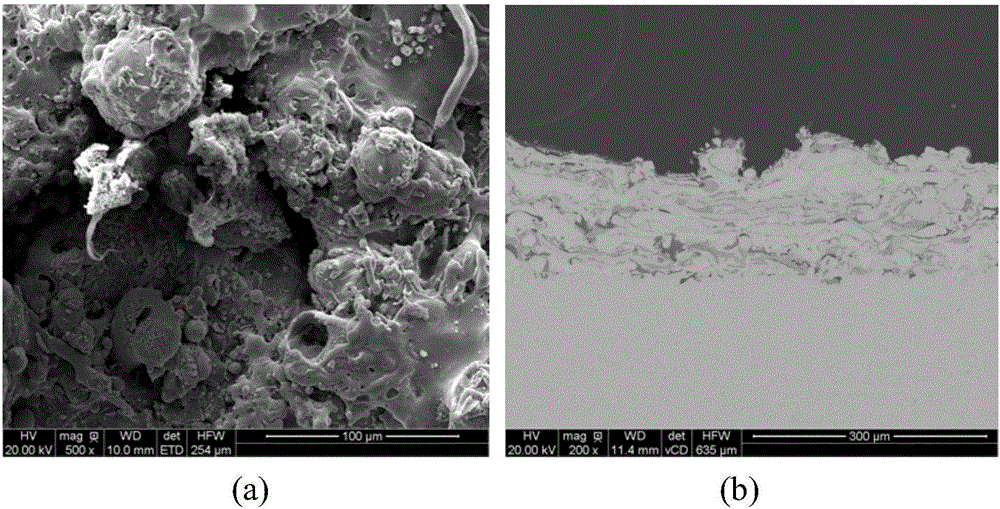

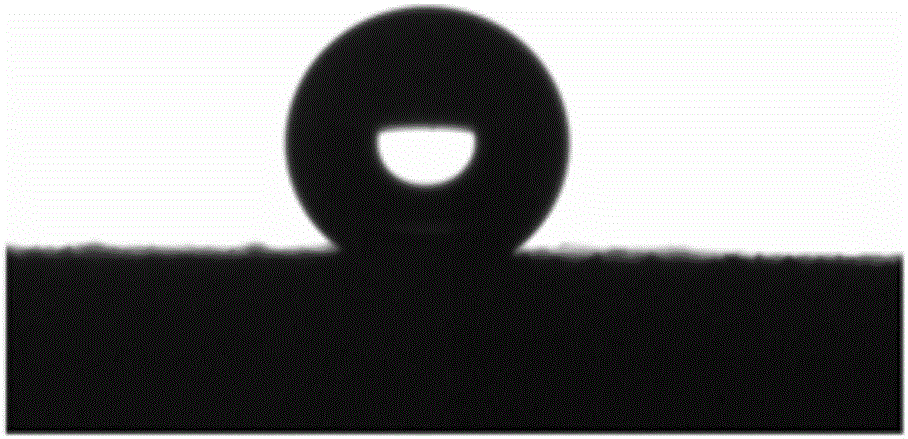

[0048] (3) Characterization...

Embodiment 2

[0055] In this embodiment, the base material is cast iron, the coating has a good bonding force with the base, and the thickness of the coating is 300 μm. The concrete preparation method of this superhydrophobic functional coating:

[0056] (1) Preparation of powder core wire material: the coat of the powder core wire material is pure aluminum, the width of the aluminum strip is 8mm, and the thickness is 0.3mm. The powder core is a mixed powder of metallic pure aluminum and polyfluoroethylene propylene. 40-60 μm, FEP powder is 5-10 μm, the mass ratio of metal pure aluminum to FEP is 5:5, the diameter of powder core wire is 2mm, and the powder coating rate is 15wt.%.

[0057] (2) Coating preparation: prepared by supersonic arc spraying process, the specific spraying parameters are: current 100A, voltage 38V, compressed air pressure 0.8MPa, spraying distance 250mm, arc gun moving speed 25mm / s, spraying times 4 times .

[0058] (3) Characterization of coating performance: The m...

Embodiment 3

[0060] In this embodiment, the base material is cast iron, the coating has a good bonding force with the base, and the thickness of the coating is 300 μm. The concrete preparation method of this superhydrophobic functional coating:

[0061] (1) Preparation of powder core wire material: the powder core wire coat is a nickel-chromium alloy strip, the strip width is 12mm, and the thickness is 0.3mm. The powder core is a mixed powder of metal nickel-chromium alloy powder and polytetrafluoroethylene, wherein, The metal nickel-chromium alloy powder is 40-60 μm, the polytetrafluoroethylene powder is 25 μm, the mass ratio of metal nickel-chromium alloy powder to polytetrafluoroethylene is 8:2, the diameter of the powder core wire is 2mm, and the powder coating rate is 25wt. %.

[0062] (2) Coating preparation: prepared by supersonic arc spraying process, the specific spraying parameters are: current 150A, voltage 40V, compressed air pressure 0.8MPa, spraying distance 300mm, arc gun m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com