Composite sealing ring for low-temperature valve

A compound sealing ring, sealing ring technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems affecting valve sealing performance, cold flow and stress relaxation, sealing specific pressure reduction, etc., to achieve good elasticity, storage powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

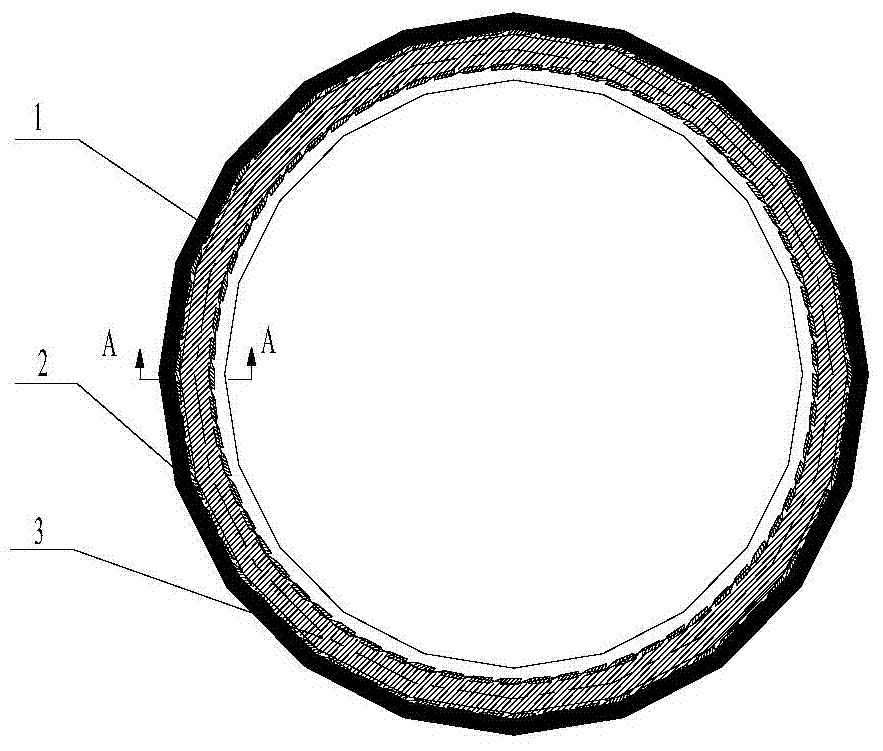

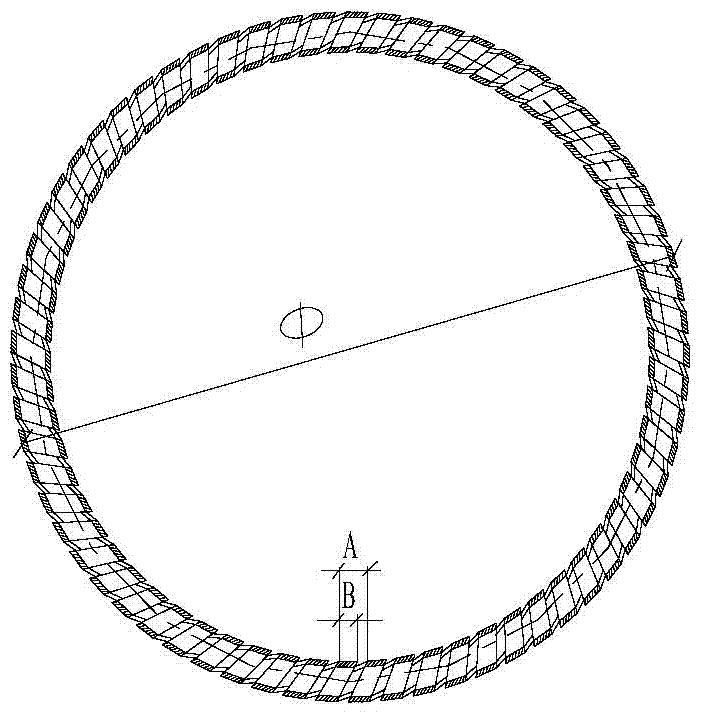

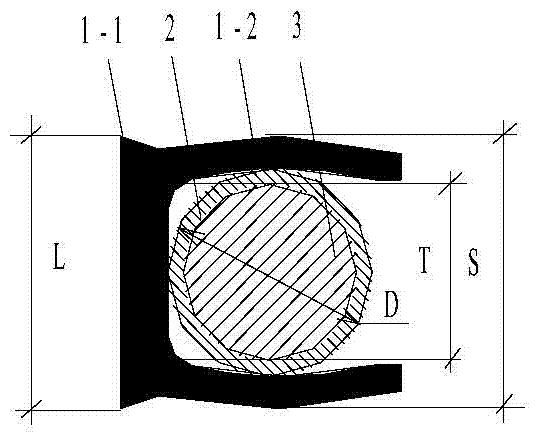

[0015] This embodiment is used for the compound sealing ring of cryogenic valve such as figure 1 , figure 2 , image 3 As shown, the sealing ring jacket 1 comprising modified polytrifluorochloroethylene material, the cross section of the sealing ring jacket 1 has a straight base side 1-1 forming an outer circular surface, and the base side 1-1 extends out of adjacent Containing side 1-2 at both ends and perpendicular to basic side 1-1. A metal energy storage spring 2 with a hollow circular section is clamped in the C-shaped cross-section ring groove formed by the base side 1-1 and the two containing sides 1-2. belt composition. The ratio of the internal distance T of the two containment sides 1-2 in the natural state to the diameter D of the hollow circle of the metal energy storage spring 2 section is 0.8 (can be selected in the range of 0.7--0.9 according to needs), and the two containment sides 1-2 clamp the metal The ratio of the maximum outer distance S formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com