A dry double-pulling lithium battery diaphragm production process

A lithium battery separator and production process technology, applied in the field of dry double-draw lithium battery separator production technology, can solve the problems of immature wet separator technology, low capacity utilization rate, etc., and achieve increased porosity, low equipment cost, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

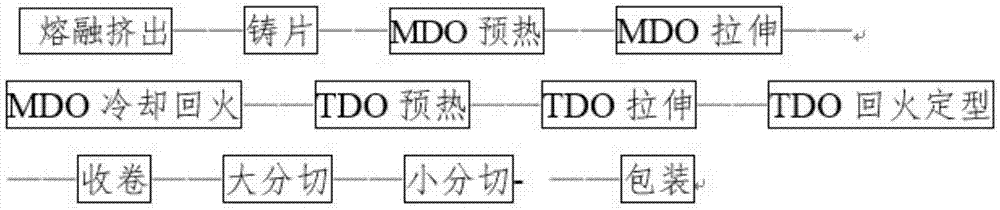

[0046] A kind of dry method double-drawing lithium battery diaphragm production technique, process step is as follows (referring to figure 1 ):

[0047] 1) Ingredients:

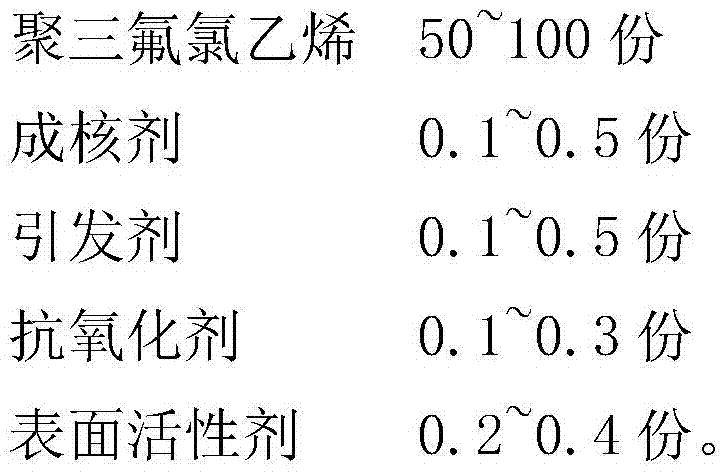

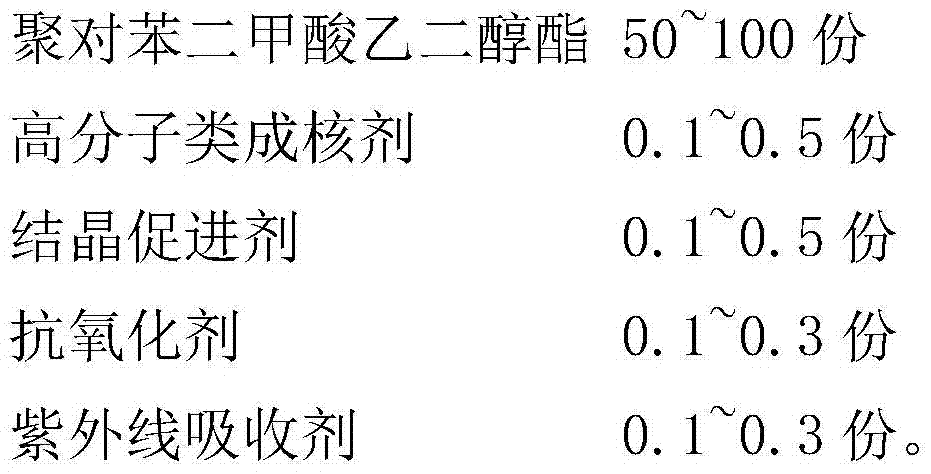

[0048] Weigh 100 parts of PP / PE, 10 parts of modified poly(p-polychlorotrifluoroethylene), 10 parts of modified polyethylene terephthalate, 0.5 parts of cyclohexane, 2 parts of toluene, nano-carbonized 5 parts of silicon, 0.5 parts of carbon fiber, 2 parts of polyethylene wax;

[0049] 2) cast piece

[0050] The raw materials in step 1) are mixed, heated, fed into an extruder to be melted and extruded, and then cooled and cast into a thick sheet on a casting roll;

[0051] 3) MDO preheating, MDO stretching

[0052] The thick sheet in step 2) is preheated and stretched by MDO technology (longitudinal stretching), and then cooled and tempered to make a film; stretching the film along the machine direction can improve the properties of the film, such as stiffness and flatness , tensile strength and porosity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com