Non-woven fabric

A non-woven, mass fraction technology, used in non-woven fabrics, textiles and papermaking, cellulose/protein conjugated rayon and other directions, can solve problems such as easy damage and insufficient strength of non-woven fabrics, and achieve The effect of reducing embrittlement temperature, good strength and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

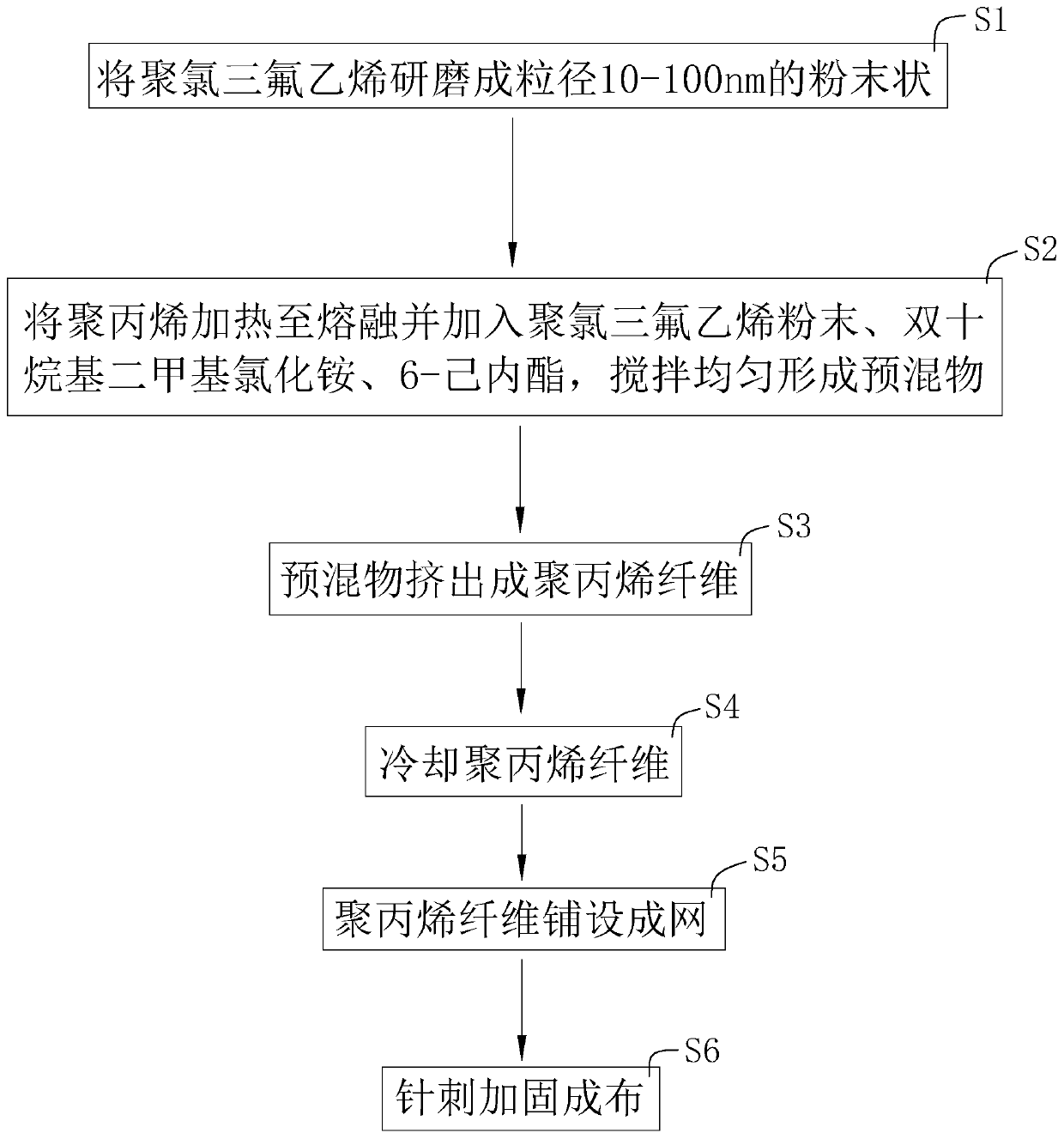

[0061] A kind of non-woven fabric, refer to figure 1 , the preparation method of non-woven fabric is as follows:

[0062] S1. Grinding polychlorotrifluoroethylene into a powder with a particle size of 10-100nm by a grinder;

[0063] S2. Add 100kg of polypropylene to the stirred tank and heat it to 160°C to melt the polypropylene, then add 30kg of polychlorotrifluoroethylene powder, 10kg of didecyldimethylammonium chloride, and 3kg of 6-caprolactone. Rotate at 80r / min, stir for 3min, and stir evenly to form a premix;

[0064] S3. The premix is discharged into the extruder and the premix is extruded into polypropylene fibers with a diameter of 12 μm through a spinneret;

[0065] S4. the polypropylene fiber is overwater cooled and air-dried;

[0066] S5. Cutting the polypropylene fiber to control the length to be 1m, randomly placing the polypropylene fiber with a length of 1m to form a net;

[0067] S6. Acupuncture and reinforcement of the reticular polypropylene fibers ...

Embodiment 2

[0069] The difference with embodiment 1 is:

[0070]In step S2, the addition amount of polypropylene is 100 kg, the addition amount of polychlorotrifluoroethylene powder is 37.5 kg, the addition amount of didecyl dimethyl ammonium chloride is 12.5 kg, and the addition amount of 6-caprolactone is 4 kg.

Embodiment 3

[0072] The difference with embodiment 1 is:

[0073] In step S2, the addition amount of polypropylene is 100 kg, the addition amount of polychlorotrifluoroethylene powder is 45 kg, the addition amount of didecyl dimethyl ammonium chloride is 15 kg, and the addition amount of 6-caprolactone is 5 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com