Conjugated polymer containing iridium complex and preparation of electrical storage device thereof

A conjugated polymer, iridium complex technology, used in static memory, chemical instruments and methods, digital memory information, etc., can solve problems to be further developed, achieve good machining performance, reduce read and write voltage, reduce processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

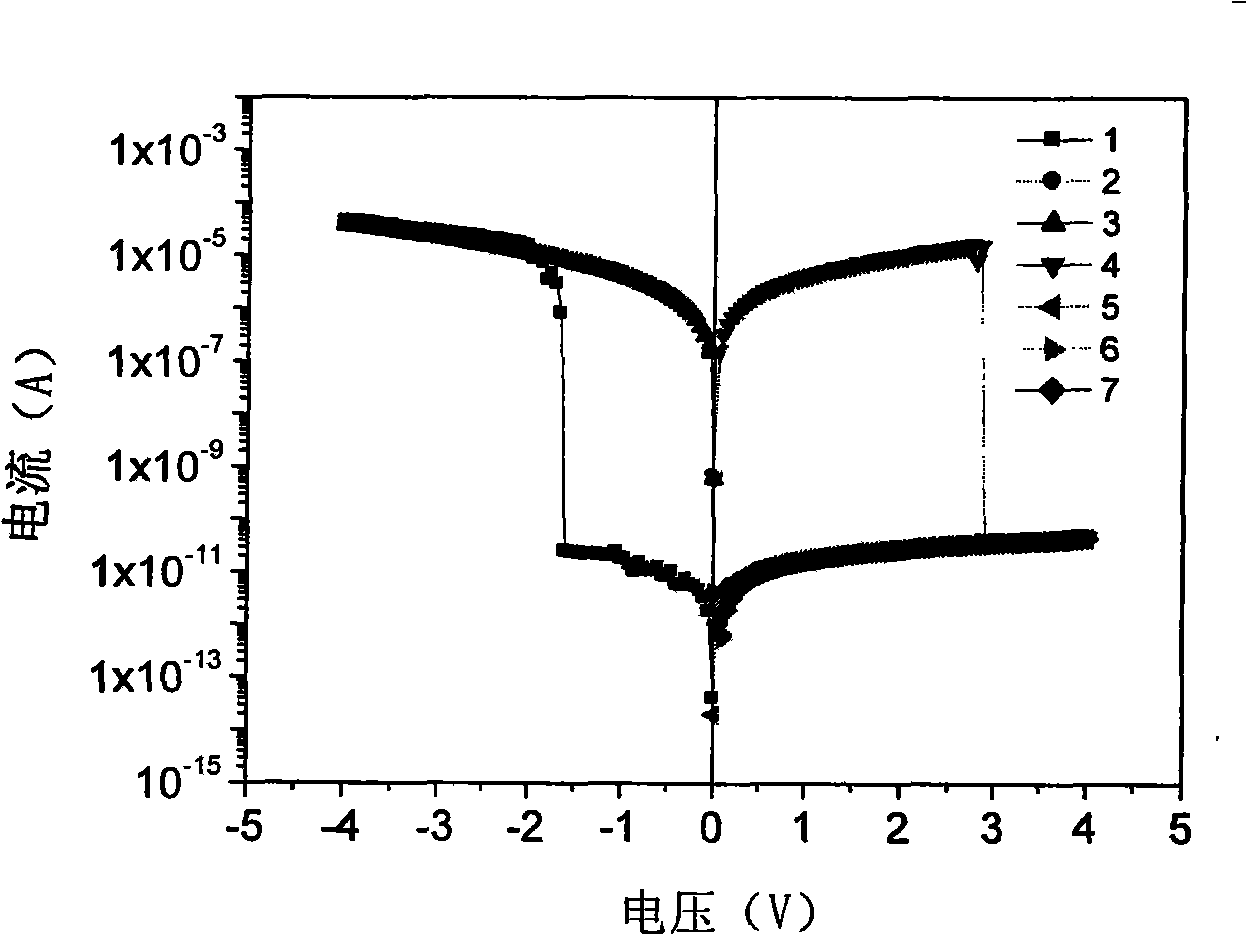

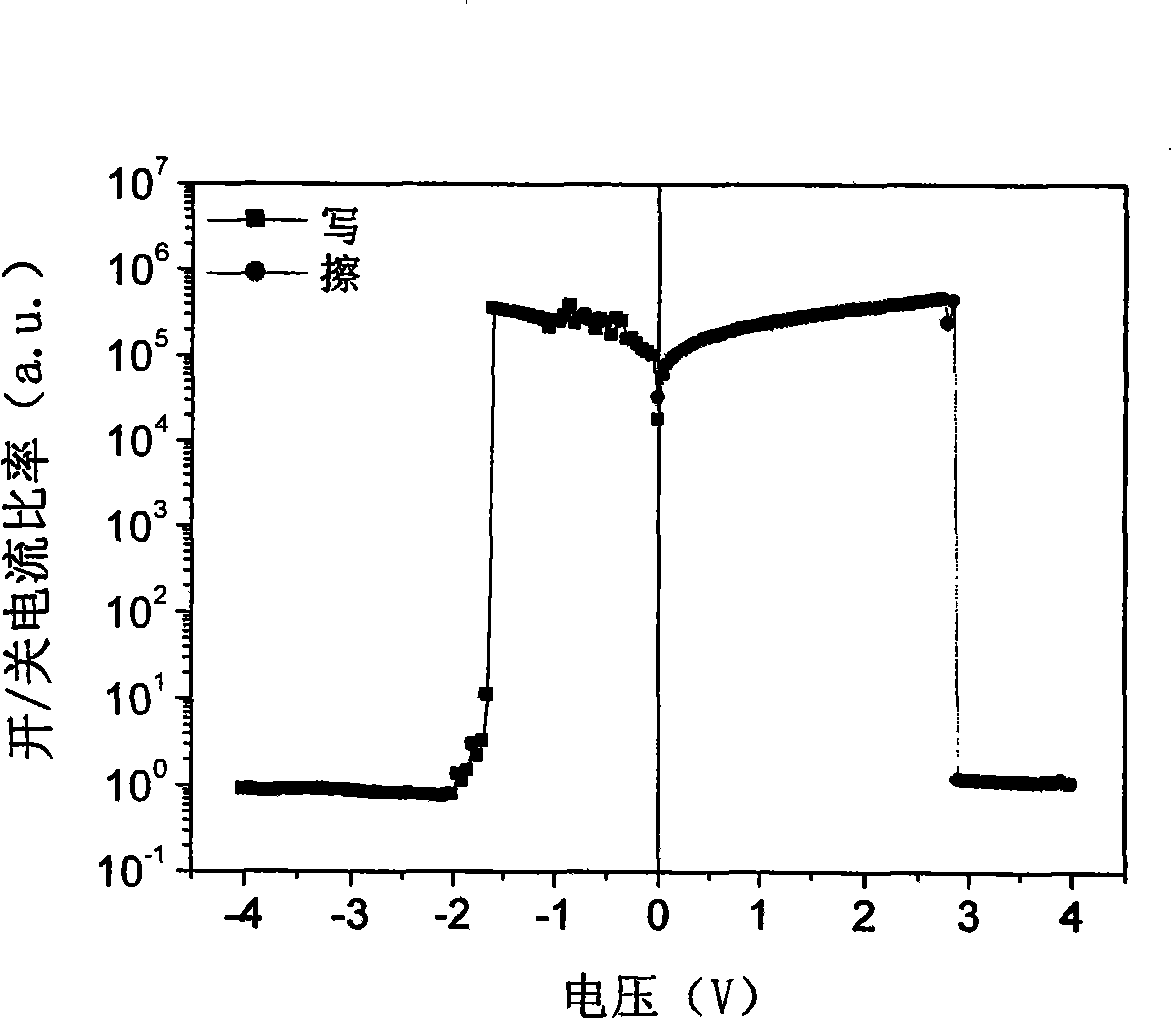

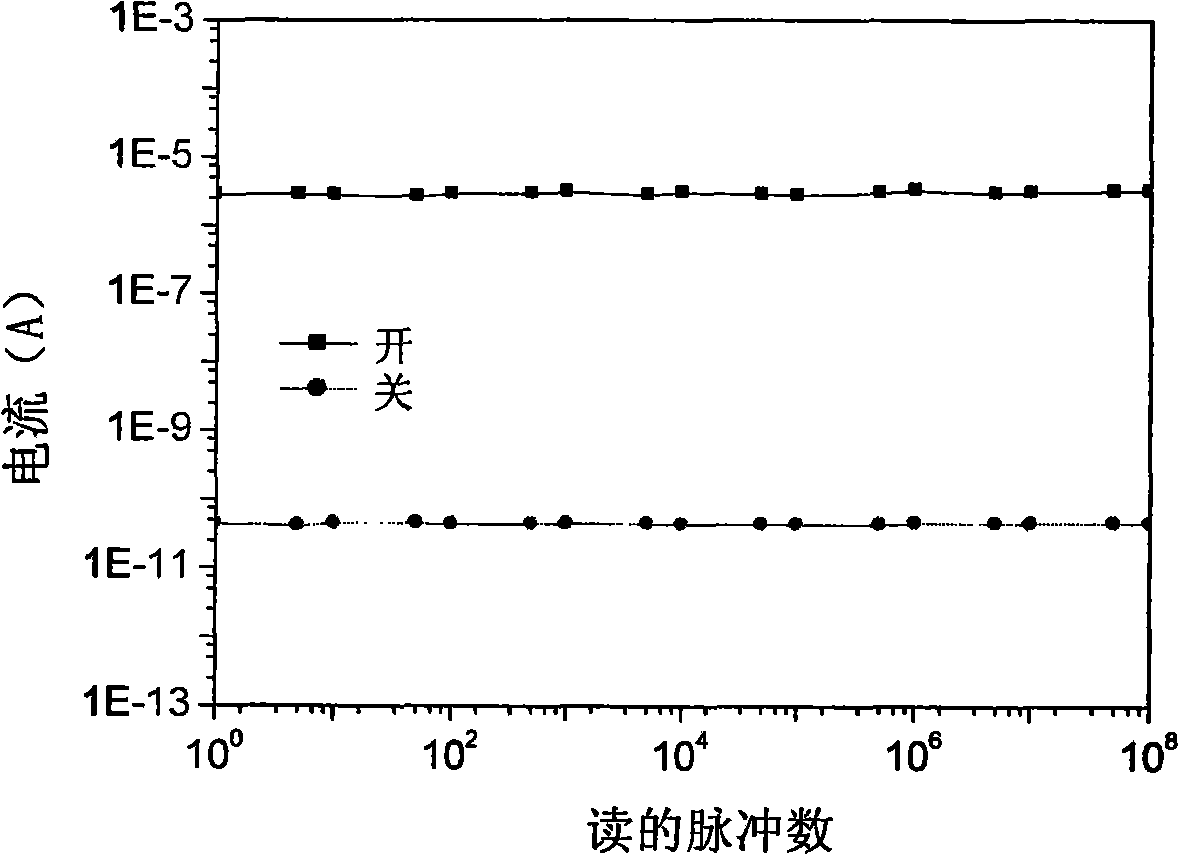

Embodiment 1

[0036]The ITO conductive glass was washed with water, acetone and 2-propanol in ultrasonic for 15 minutes respectively. Using the compound with the following structure as the storage material, prepare a toluene solution with a concentration of 10mg / mL, and spin-coat it on the ITO conductive glass. The solvent was removed under vacuum and the polymer film was about 50 nm thick. Al is then evaporated as the upper electrode. The device test area is 0.4×0.4 mm2. The schematic diagram of the device structure is shown in the figure below. Measure the current-voltage curve of the device to determine whether the material has electrical bistability, turn on and off voltage, and repeated erasing and writing capabilities; measure the constant voltage read / write pulse current to evaluate the current difference between the "0" and "1" signals of the device, and Read, write, and erase stability of the device; test the current response of the device in the on and off states, evaluate the ...

Embodiment 2

[0039] The ITO conductive glass was washed with water, acetone and 2-propanol in ultrasonic for 15 minutes respectively. Using the compound with the following structure as the storage material, prepare a toluene solution with a concentration of 10mg / mL, and spin-coat it on the ITO conductive glass. The solvent was removed under vacuum and the polymer film was about 50 nm thick. Then evaporate Au as the upper electrode. The device test area is 0.2×0.2 mm2. Measure the current-voltage curve of the device to determine whether the material has electrical bistability, turn on and off voltage, and repeated erasing and writing capabilities; measure the constant voltage read / write pulse current to evaluate the current difference between the "0" and "1" signals of the device, and Read, write, and erase stability of the device; test the current response of the device in the on and off states, evaluate the read / write speed of the device, etc.; use the accelerated aging test to evaluate...

Embodiment 3

[0042] The ITO conductive glass was washed with water, acetone and 2-propanol in ultrasonic for 15 minutes respectively. Using the compound with the following structure as the storage material, prepare a toluene solution with a concentration of 10mg / mL, and spin-coat it on the ITO conductive glass. The solvent was removed under vacuum and the polymer film was about 50 nm thick. Cu was then evaporated as the upper electrode. The device test area is 0.15×0.15 mm2. Measure the current-voltage curve of the device to determine whether the material has electrical bistability, turn on and off voltage, and repeated erasing and writing capabilities; measure the constant voltage read / write pulse current to evaluate the current difference between the "0" and "1" signals of the device, and Read, write, and erase stability of the device; test the current response of the device in the on and off states, evaluate the read / write speed of the device, etc.; use the accelerated aging test to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com