Waterproof fabric material and preparation method thereof

A fabric material, waterproof technology, applied in the directions of melt spinning, stretch spinning, rayon manufacturing, etc., can solve the problems of poor tear resistance and abrasion resistance of fabrics, difficult dyeing and finishing, loss of waterproof performance, etc. Achieve the effect of reducing friction, easy industrial production, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

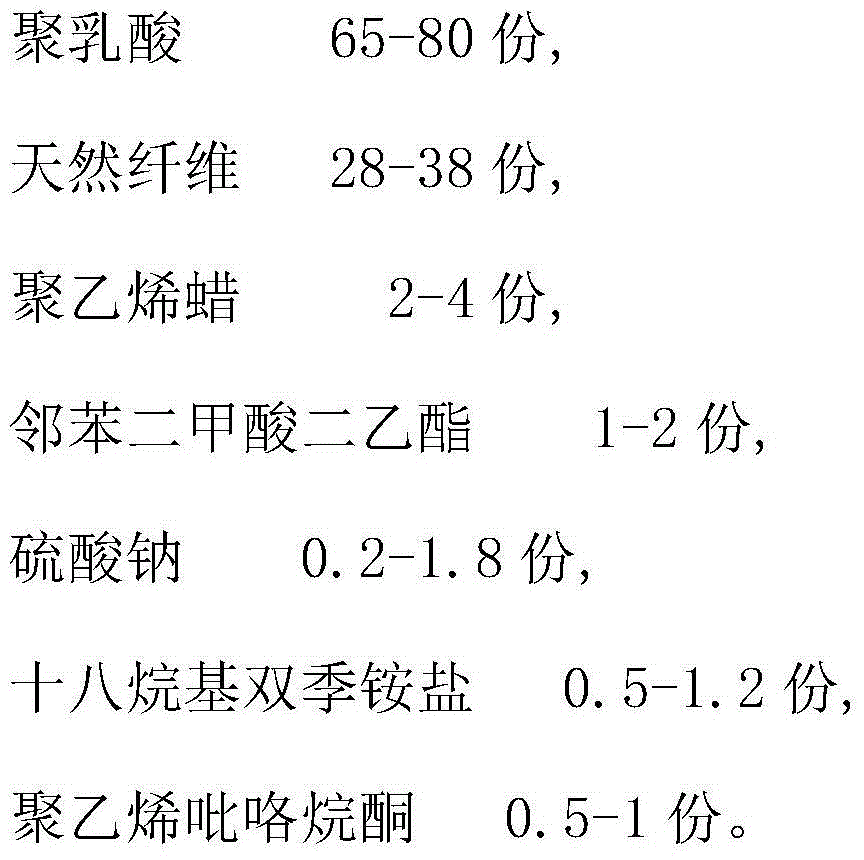

Embodiment 1

[0021] (1) 65kg of L-type polylactic acid, 28kg of Modal fiber, 2kg of polyethylene wax, 1kg of diethyl phthalate, 0.2kg of sodium sulfate, 0.5kg of octadecyl diquaternary ammonium salt and 0.5kg of polyvinylpyrrolidone;

[0022] (2) Add to the shearing machine and mix, add citric acid to adjust the pH to 6, mix uniformly, melt at 195°C under airtight conditions, spin at a spinning speed of 1500m / min, and make it through drawing treatment. Waterproof fabric material.

[0023] Table 1 shows the performance test results of the waterproof fabric material.

Embodiment 2

[0025] (1) 65kg of L-type polylactic acid, 38kg of Modal fiber, 2kg of polyethylene wax, 1kg of diethyl phthalate, 0.2kg of sodium sulfate, 0.5kg of octadecyl diquaternary ammonium salt and 0.5kg of polyvinylpyrrolidone;

[0026] (2) Add to the shearing machine and mix, add citric acid to adjust the pH to 6, mix uniformly, melt at 195°C under airtight conditions, spin at a spinning speed of 1500m / min, and make it through drawing treatment. Waterproof fabric material.

[0027] Table 1 shows the performance test results of the waterproof fabric material.

Embodiment 3

[0029] (1) 80kg of L-type polylactic acid, 38kg of ramie fiber, 4kg of polyethylene wax, 2kg of diethyl phthalate, 1.8kg of sodium sulfate, 1.2kg of octadecyl diquaternary ammonium salt and 1kg of polyvinylpyrrolidone;

[0030] (2) Add to the shearing machine and mix, add citric acid to adjust the pH to 6.5, mix uniformly, melt at 220°C under airtight conditions, spin at a spinning speed of 2000m / min, and make it through drawing treatment Waterproof fabric material.

[0031] Table 1 shows the performance test results of the waterproof fabric material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com