High-strength and high-conductivity wrought aluminum alloy and preparation method thereof

A technology of deforming aluminum alloy and high conductivity, applied in metal rolling, metal rolling, temperature control and other directions, can solve the problems of high energy consumption, complex process, long production cycle, etc., achieve simple operation process and reduce production cost , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

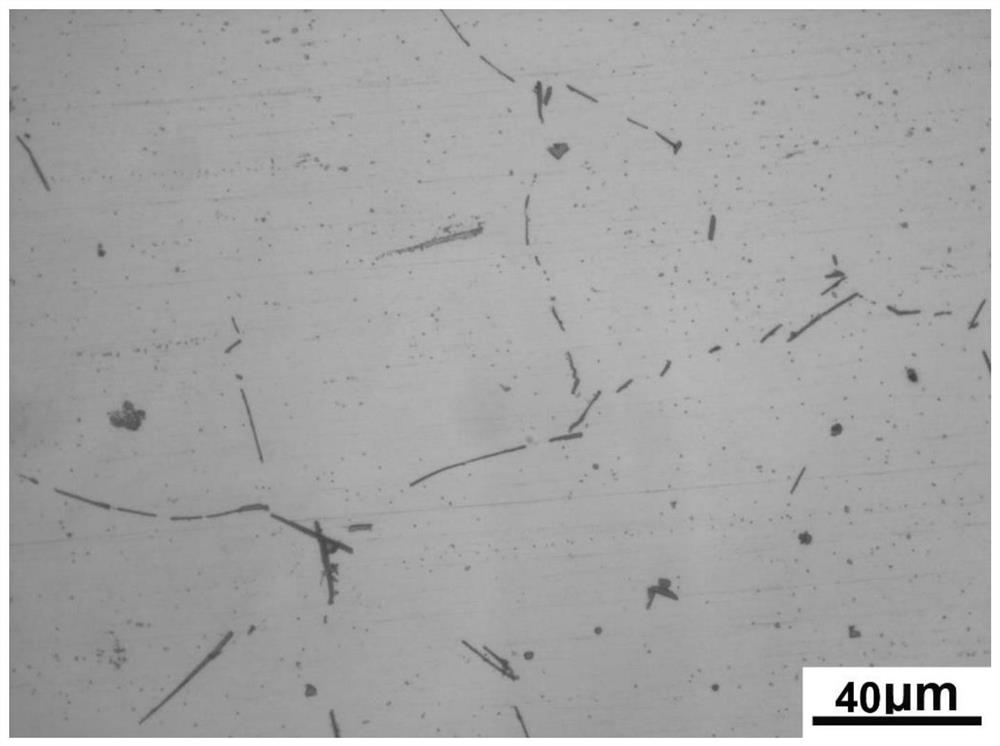

Embodiment 1

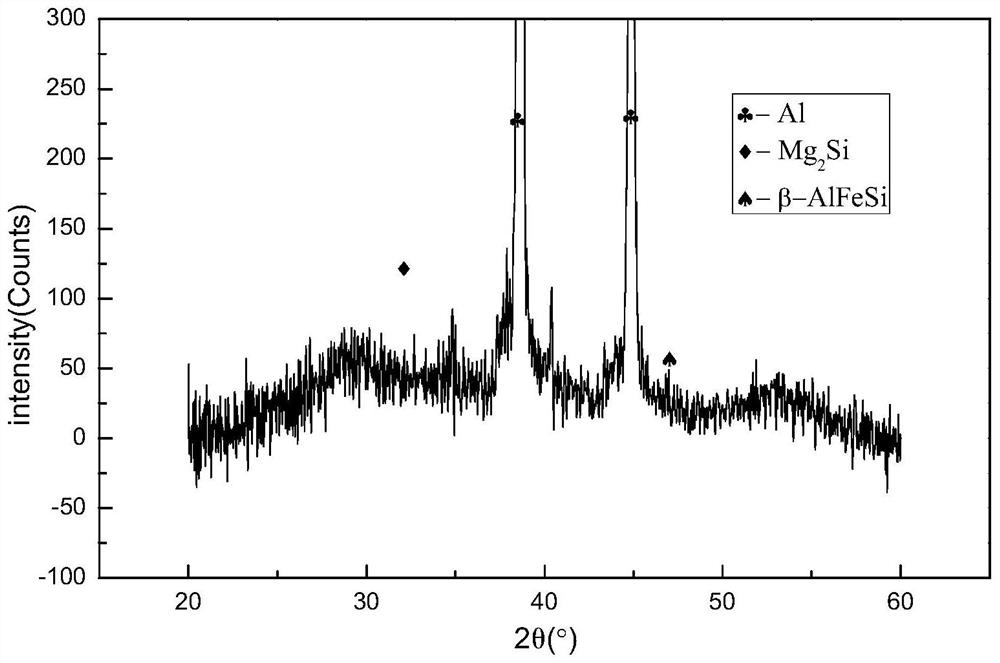

[0057] The alloy composition of this example is Al-0.6Mg-0.4Si-0.2Fe-0.3Ni-0.1Cu-0.06B, using industrial pure aluminum, Al-10Mg, Al-20Si, Al-20Fe, Al-10Ni and Al- The 50Cu master alloy is prepared, and the composition is as follows by mass percentage: Mg: 0.6%; Si: 0.4%; Fe: 0.2%; Ni: 0.3%; Cu: 0.1%; B: 0.06%, and the rest is Al.

[0058] Compared with the comparative example, the main differences of the preparation process in this example are: the alloy element Ni is added; sub-rapid solidification is adopted in the casting preparation process, and the homogenization treatment process is canceled. The preparation process mainly includes: alloy smelting and melt treatment; alloy casting and sub-rapid solidification preparation, alloy rolling plastic forming, and alloy solution-aging heat treatment. The detailed process flow and its parameters are as follows:

[0059] (1) Alloy smelting and melt treatment

[0060] The weighed industrial pure aluminum is melted, and the meltin...

Embodiment 2

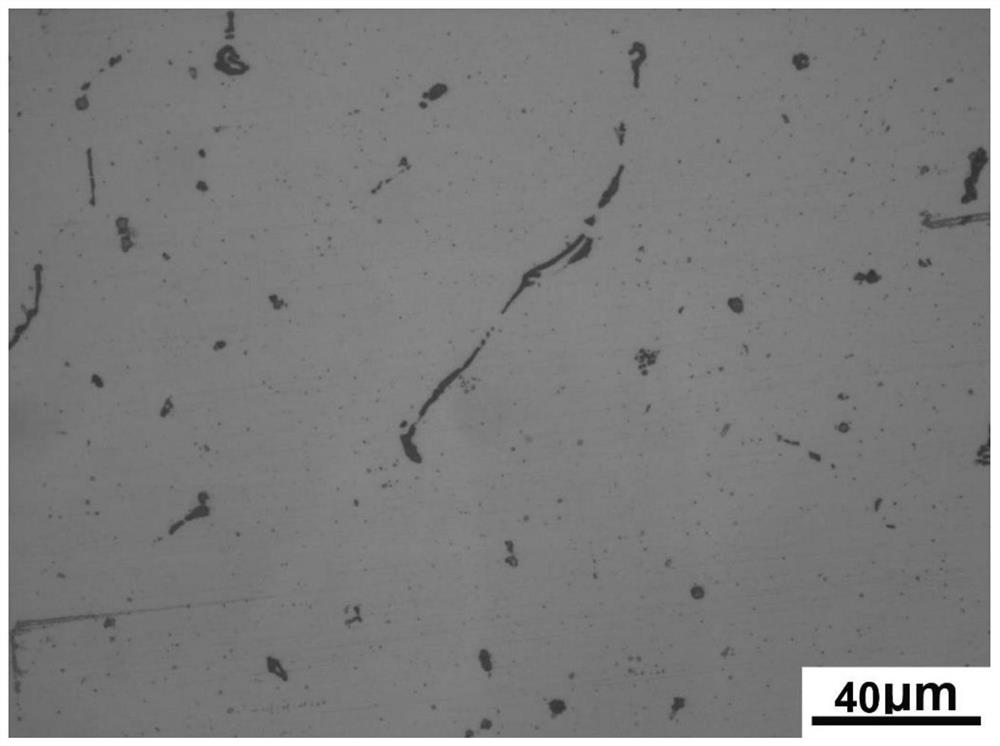

[0079] The element composition of the alloy in this example is the same as that in Example 1, except that the element content is slightly different. The composition of the alloy in this embodiment is: Mg: 0.8%; Si: 0.6%; Fe: 0.1%; Ni: 0.2%; Cu: 0.1%; B: 0.09%, and the rest is Al. The used raw material of compound alloy is identical with embodiment 1.

[0080] The alloy preparation process of this embodiment is basically the same as that of Embodiment 1, including: alloy smelting and melt treatment; alloy casting and sub-rapid solidification preparation, alloy rolling plastic forming, and alloy solution-aging heat treatment. The difference is that the preparation process parameters are different. details as follows:

[0081] (1) Alloy smelting and melt treatment

[0082] The weighed industrial pure aluminum is melted, and the melting temperature is 730°C. After all the industrial pure aluminum is melted, add Al-10Mg, Al-20Si, Al-20Fe and Al-50Cu master alloys. After the in...

Embodiment 3

[0093] The element composition of the alloy in this example is the same as that in Example 1, except that the element content is slightly different. The composition of the alloy in this embodiment is: Mg: 0.3%; Si: 0.2%; Fe: 0.3%; Ni: 0.5%; Cu: 0.1%; B: 0.05%, and the rest is Al. The used raw material of compound alloy is identical with embodiment 1.

[0094] The alloy preparation process of this embodiment is basically the same as that of Embodiment 1, including: alloy smelting and melt treatment; alloy casting and sub-rapid solidification preparation, alloy rolling plastic forming, and alloy solution-aging heat treatment. The difference is that the preparation process parameters are different. details as follows:

[0095] (1) Alloy smelting and melt treatment

[0096] Melt the weighed industrial pure aluminum with a melting temperature of 700°C. After all the industrial pure aluminum is melted, add Al-10Mg, Al-20Si, Al-20Fe and Al-50Cu master alloys. After the intermedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com