Resin composition and prepared prepreg thereof, laminated board

A technology of resin composition and prepreg, which is applied in the fields of prepreg and laminate, can solve problems such as the inability to meet the high-frequency and high-speed requirements of electronic circuit substrates, and meet the needs of high-speed and high-frequency use. Effect of high machinability and glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092]In a preferred embodiment of the present invention, the preparation method of the prepreg comprises the following steps: impregnating the base material in the glue solution made of the resin composition, and then placing the base material impregnated with the glue solution in an oven for heating After drying, a prepreg can be obtained.

[0093] According to the third aspect of the present invention, the present invention provides a laminate, comprising at least one prepreg provided by the present invention.

[0094] The laminate provided by the present invention is prepared from the resin composition provided by the present invention. It not only has good machining performance, but also has low dielectric loss and high glass transition temperature. It also has UV-blocking function and can meet the requirements of PCB. The use requirements of high-speed and high-frequency substrate materials.

[0095] According to the fourth aspect of the present invention, the present i...

Embodiment 9

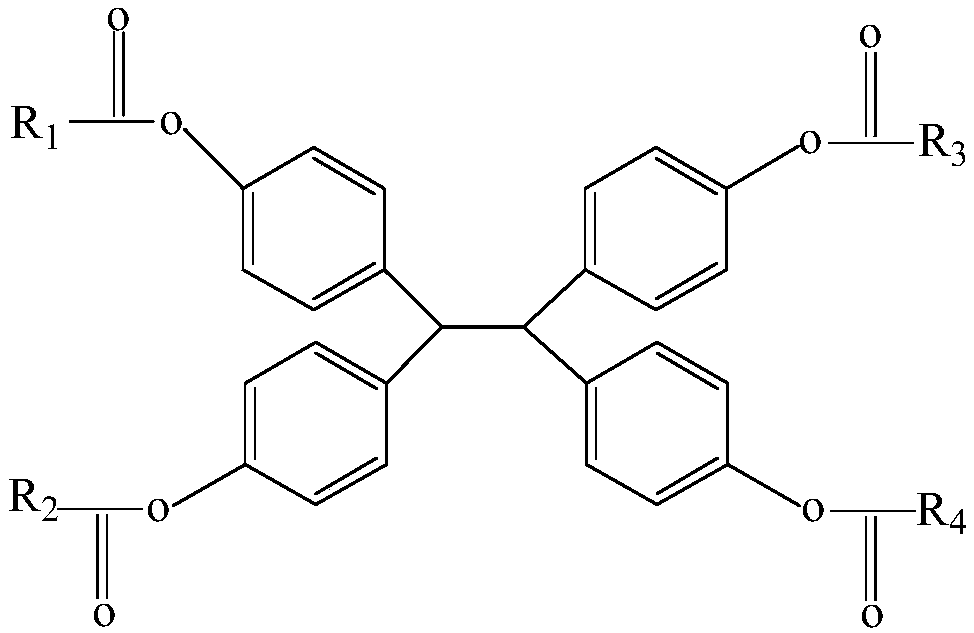

[0130] This embodiment provides a resin composition. The difference between this embodiment and Embodiment 8 is that the active ester curing agent has the following structure:

[0131]

[0132] Among them, R 1 , R 2 , R 3 and R 4 Both are ethyl.

Embodiment 10

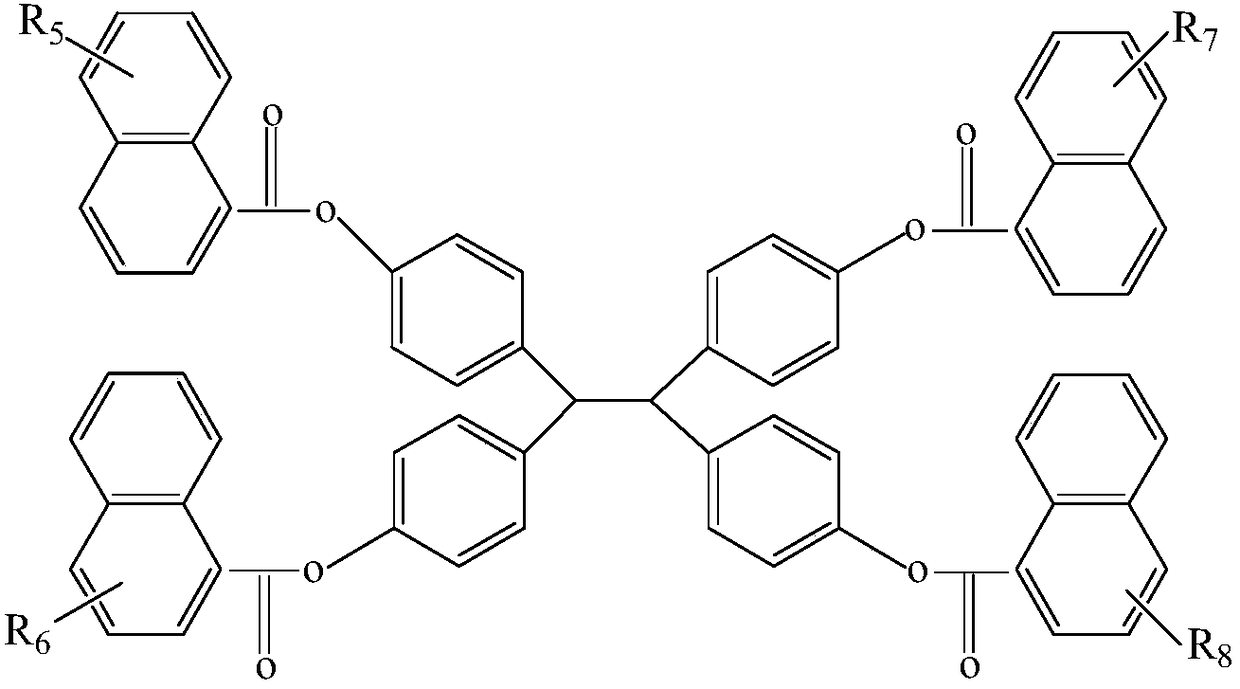

[0134] This embodiment provides a resin composition. The difference between this embodiment and Embodiment 8 is that the active ester curing agent has the following structure:

[0135]

[0136] Among them, R 1 , R 2 , R 3 and R 4 All are allyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com