Nature-imitated travertine as well as composition and manufacture method thereof

A production method and a natural imitation technology, applied in the field of building decoration materials, can solve the problems of poor variety and quality, affecting use, environmental hazards, etc., and achieve the effects of good processability, production cost savings, and strong economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. The composition and weight ratio of the main color paste and the auxiliary color paste

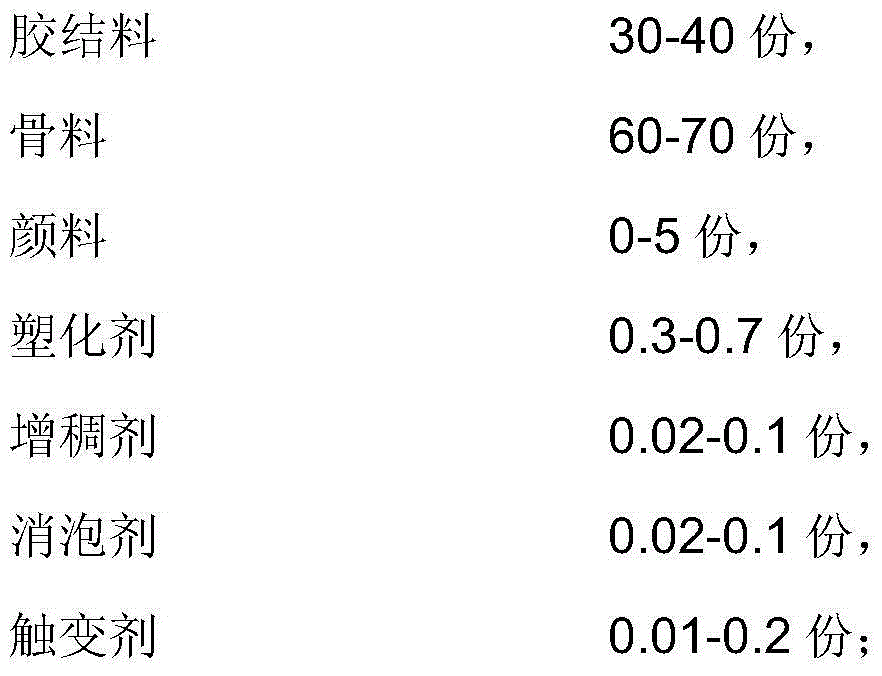

[0059] (1) The main color paste components and their weight ratios include:

[0060]

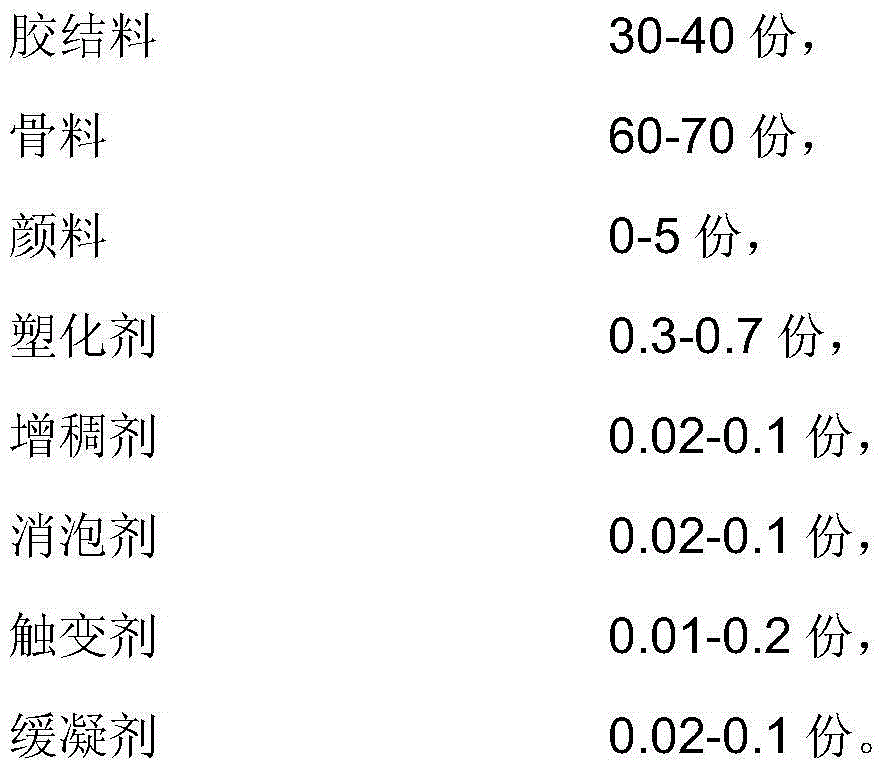

[0061] (2) The components of the auxiliary color paste and their weight ratio include:

[0062]

[0063]

[0064] Second, the production method of imitating natural travertine

[0065] Step 1: Prepare the low-fluidity main color slurry according to the components of the main color slurry in the above (1) and the weight ratio;

[0066] Step 2: According to the above (2) auxiliary color paste components and their weight ratio, prepare high fluidity, high viscosity auxiliary color paste, add amphoteric metal 20-40 mesh aluminum powder, and stir for 50-70s to obtain the mixture ;

[0067] Step 3: Add the main color slurry described in step 1 to the mixture described in step 2, and stir slowly for 10-15 seconds to obtain a slurry;

[0068] Step 4: Pouring the slurry described in step 3 into a large-volume squa...

Embodiment 2

[0071] 1. The composition and weight ratio of the main color paste and the auxiliary color paste

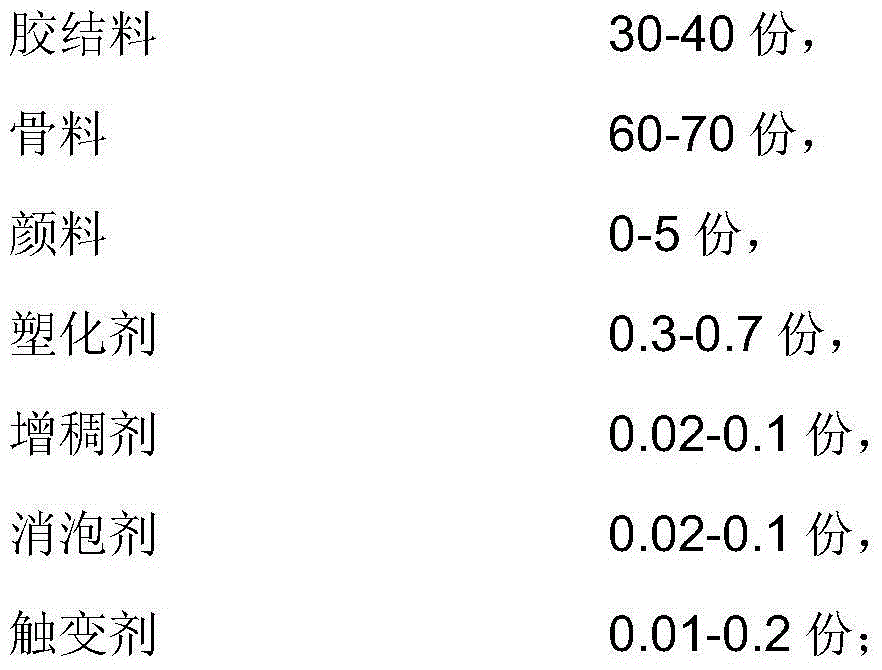

[0072] (1) The main color paste components and their weight ratios include:

[0073]

[0074] (2) The components of the auxiliary color paste and their weight ratio include:

[0075]

[0076] Second, the production method of imitating natural travertine

[0077] Step 1: Prepare the low-fluidity main color slurry according to the components of the main color slurry in the above (1) and the weight ratio;

[0078] Step 2: According to the above (2) auxiliary color paste components and their weight ratio, prepare high fluidity and high viscosity auxiliary color paste, add amphoteric metal 10-20 mesh aluminum foil, and stir for 50-70s to obtain the mixture ;

[0079] Step 3: Add the main color slurry described in step 1 to the mixture described in step 2, and stir slowly for 10-15 seconds to obtain a slurry;

[0080] Step 4: Pouring the slurry described in step 3 into a large-volume square mater...

Embodiment 3

[0083] 1. The composition and weight ratio of the main color paste and the auxiliary color paste

[0084] (1) The main color paste components and their weight ratios include:

[0085]

[0086]

[0087] (2) The components of the auxiliary color paste and their weight ratio include:

[0088]

[0089] Second, the production method of imitating natural travertine

[0090] Step 1: Prepare the low-fluidity main color slurry according to the components of the main color slurry in the above (1) and the weight ratio;

[0091] Step 2: According to the above (2) auxiliary color paste components and their weight ratio, prepare high fluidity, high viscosity auxiliary color paste, and add amphoteric metal 10-20 mesh aluminum powder, stir for 50-70s to obtain the mixture ;

[0092] Step 3: Add the main color slurry described in step 1 to the mixture described in step 2, and stir slowly for 10-15 seconds to obtain a slurry;

[0093] Step 4: Pouring the slurry described in step 3 into a large-volume squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com