Method for manufacturing high-strength cold-rolled/hot-rolled DP steel having a tensile strength grade of 590 MPa and excellent workability, as well as little deviation in the material properties thereof

A technology with excellent workability and tensile strength, applied in the direction of manufacturing tools, heat treatment furnaces, metal rolling, etc., can solve the problems of cold-rolled DP steel without proposed mechanical properties, achieve excellent workability, improve recyclability, Excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, a detailed description of the present invention will be given.

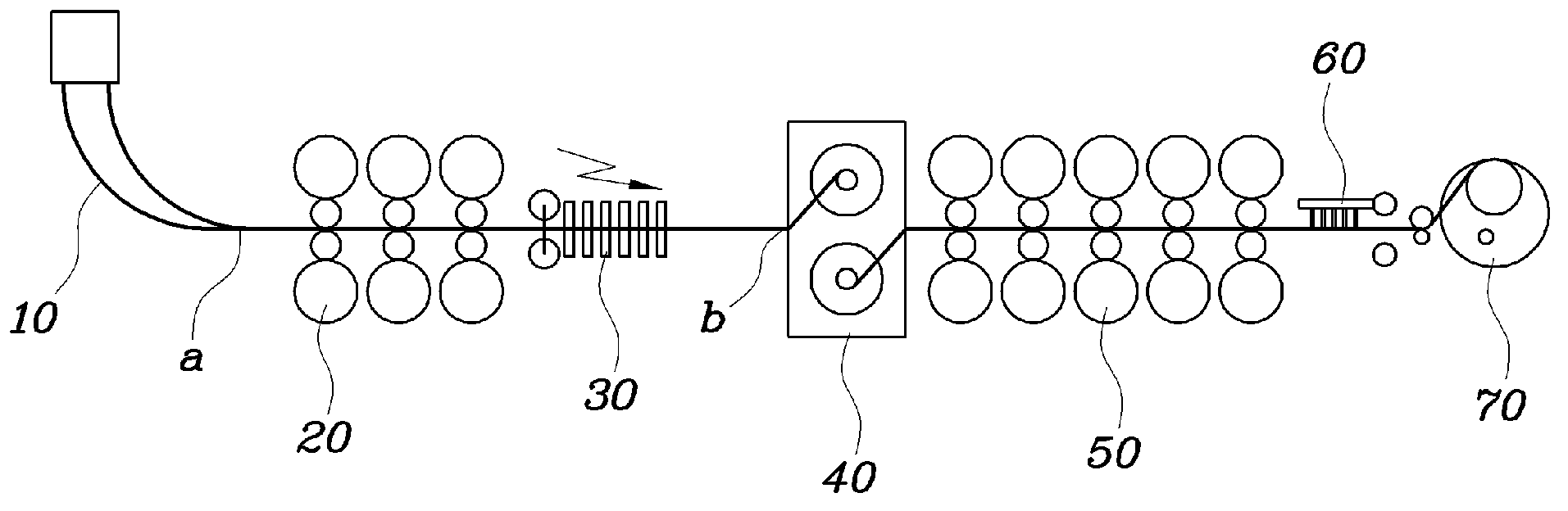

[0032] As stated above, the present invention pertains to a method of manufacturing high-strength cold-rolled DP steel using a micro-mill process using thin-slab casting technology, cf. figure 1 The micro-rolling mill process according to the present invention will be briefly described. The hot-rolled steel strip produced by the micro-mill process is subjected to known cold-rolling processes (pickling, cold rolling, continuous annealing, cooling heat treatment) to thereby obtain the final cold-rolled DP steel, the description of which is omitted.

[0033] Specifically, a thin slab (a) having a thickness of 30 mm to 150 mm is produced by the continuous casting machine 10 . The slab is thin compared to a slab having a thickness of 200 mm or more produced by a continuous casting machine using a conventional rolling mill, and thus is called a thin slab. Since a conventional slab having a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com