High CTI reinforced and flame-retarded PA6 composite material with high glowing filament and preparation method

A composite material and high-glow wire technology, which is applied in the field of high-glow wire and high CTI reinforced flame-retardant PA6 composite materials, can solve the problems of increasing the difficulty of injection molding, restricting the application of nylon, and non-ignitable drippings, etc., to achieve machinability Good effect with excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

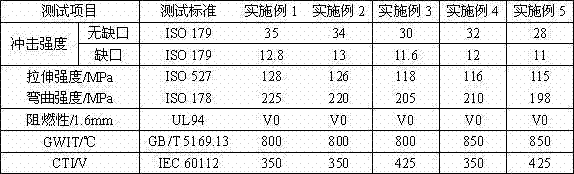

Embodiment 1~5

[0027] High glow wire high CTI reinforced flame retardant PA6 composite material and preparation method thereof comprise the following steps:

[0028] The composition of raw materials in the examples is shown in Table 1, wherein the phosphorus-nitrogen flame retardant is a compound of melamine phosphate, melamine, and pentaerythritol in a weight ratio of 3:3:4, and the compounded antimony trioxide is The compound of antimony and talcum powder in the weight ratio of 2:1, the filler is the compound of barium sulfate and talc powder in the weight ratio of 1:1, the toughening agent is ethylene ethyl acrylate, maleic anhydride grafted ethylene A compound of ethyl acrylate in a weight ratio of 1:1, a lubricant of TAF and silicone in a weight ratio of 1:1. First dry PA6 at 90°C for 4-8 hours, then put PA6 resin and 0.1-0.3% white oil by weight of PA6 resin in a high-mixer for 1-2 minutes, and then put other components together in a high-mixer. Mix in the machine for another 2-5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com