Method of preparing degradable Fe-Zn alloy pipe for intravascular stent by electroforming

A vascular stent, fe-zn technology, applied in the fields of biomedical materials and electrochemical processing, to achieve the effects of good biocompatibility, good comprehensive mechanical properties, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

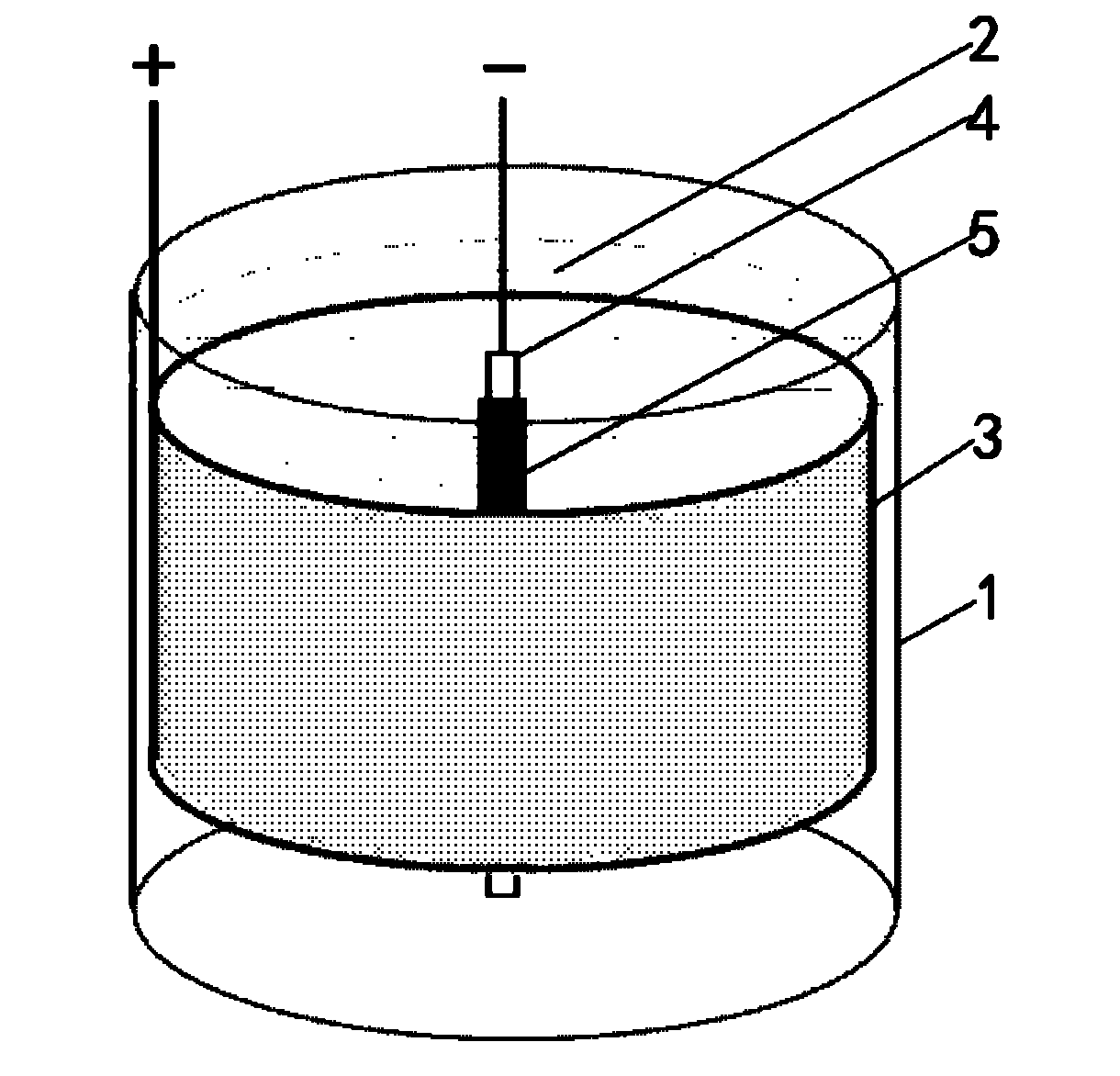

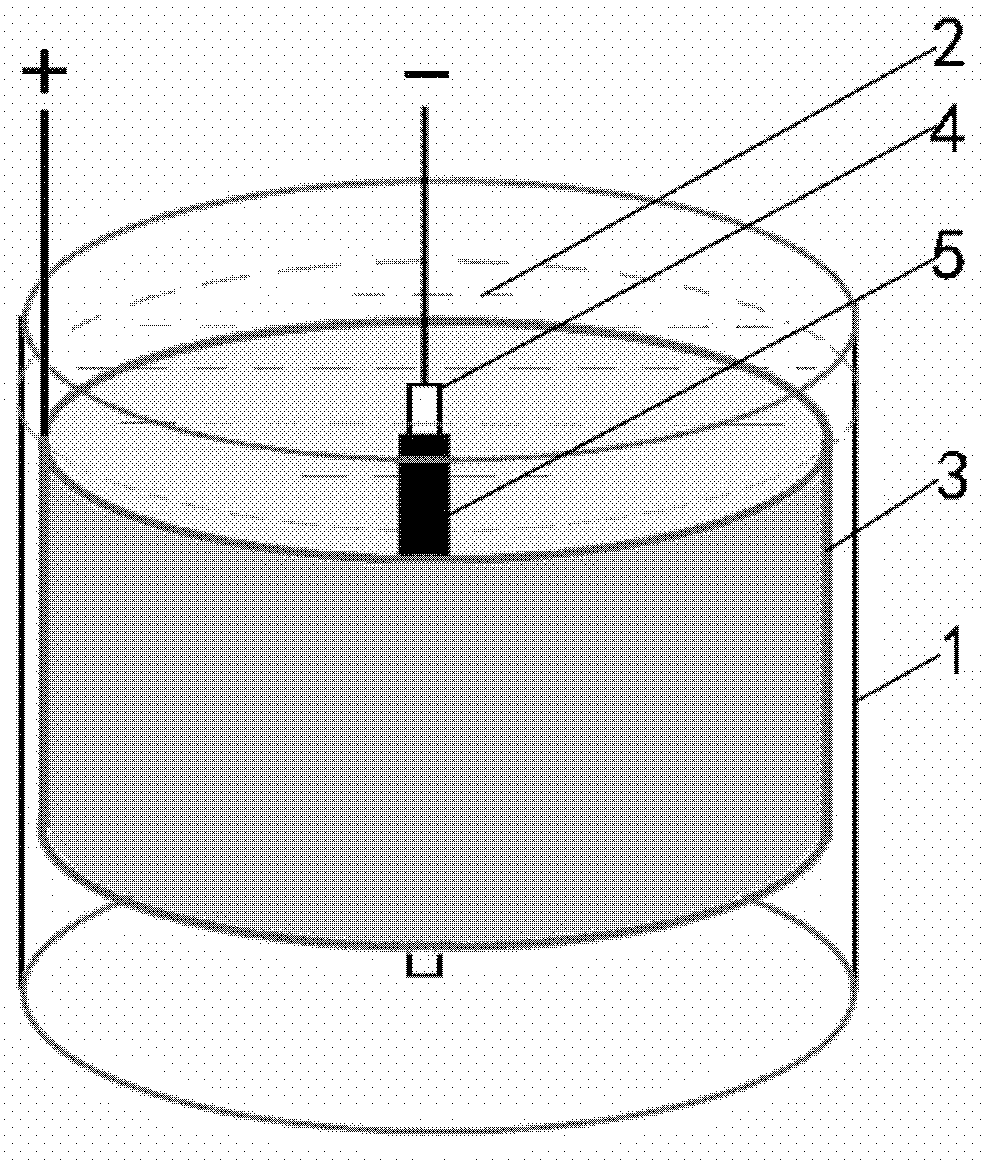

[0022] a. prepare electroforming solution 2 in electroforming tank 1, electroforming solution 2 includes: deionized water 1000g, ferrous chloride 300g, zinc chloride 10g, sodium lauryl sulfate 0.02g, sodium citrate 20g, Ascorbic acid 1.5g, sodium chloride 15g, manganese chloride 5g;

[0023] b. adjust the pH of the solution with sodium hydroxide and hydrochloric acid to keep the pH at 3.5;

[0024] c. Using DC power supply for electroforming. The cathode mandrel 4 connected to the negative pole of the power supply is made of metal tin wire with a diameter of 1.8 mm, which is submerged in the electrolyte to generate a uniform Fe-Zn alloy electroforming layer 5 with an effective length of 40 mm. The one connected to the positive pole of the power supply is an annular pure iron anode 3 with a purity of 99.9%. The cathode mandrel 4 is placed on the central axis of the annular pure iron anode 3 to ensure the uniformity of the wall thickness of the electroformed pipe. The cathode...

Embodiment 2

[0029] a. prepare electroforming solution 2 in electroforming tank 1, electroforming solution 2 includes: deionized water 1000g, ferrous chloride 300g, zinc chloride 7g, sodium lauryl sulfate 0.02g, sodium citrate 20g, Ascorbic acid 1.5g, sodium chloride 15g, manganese chloride 5g;

[0030] b. adjust the pH of the solution with sodium hydroxide and hydrochloric acid to keep the pH at 3.5;

[0031] c. Using DC power supply for electroforming. The cathode mandrel 4 connected to the negative pole of the power supply is made of metal tin wire with a diameter of 1.8 mm, which is submerged in the electrolyte to generate a uniform Fe-Zn alloy electroforming layer 5 with an effective length of 40 mm. The one connected to the positive pole of the power supply is an annular pure iron anode 3 with a purity of 99.9%. The cathode mandrel 4 is placed on the central axis of the annular pure iron anode 3 to ensure the uniformity of the wall thickness of the electroformed pipe. The cathode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com