Modified graphene enhanced aluminum-based composite material and preparation method thereof

A technology for strengthening aluminum-based and composite materials, applied in the field of metal casting, can solve problems such as difficulty in uniform metal distribution, easy agglomeration of graphene, poor interface wettability, etc., to achieve wettability, good interface bonding, and comprehensive good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

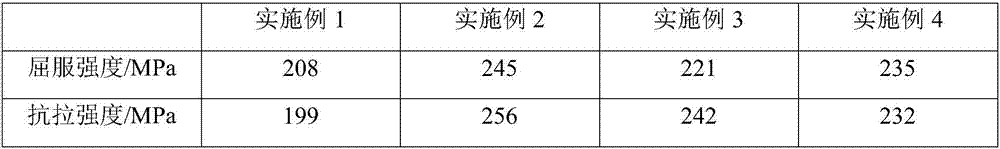

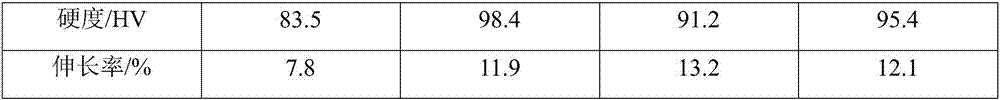

Embodiment 1

[0022] A modified graphene-reinforced aluminum-based composite material, comprising the following components, the mass fraction percent of which is: modified graphene 0.01wt.%, copper 0.3wt.%, carbon 0.2wt.%, iron 1.2wt.% , silicon carbide 0.8wt.%, lanthanum oxide 0.1wt.%, surfactant 1.9wt.%, and the balance is aluminum.

[0023] A preparation method for modified graphene-reinforced aluminum-based composite material, comprising the following steps:

[0024] (1) Graphene is added in dehydrated alcohol, m / v is 1:15, is placed in ball mill, after dispersing evenly, adds cationic surfactant, sonication 2 hours;

[0025] (2) Place the system after the ultrasonic treatment in step (1) in an oven at 40° C., remove absolute ethanol, and obtain modified graphene;

[0026] (3) Melt pure aluminum, add modified graphene when it is half melted, and keep it warm at 700°C for 30 minutes;

[0027] (4) After adding copper, carbon, iron, silicon carbide and lanthanum oxide, keep warm and stir...

Embodiment 2

[0032] A modified graphene-reinforced aluminum-based composite material, comprising the following components, the mass fraction percentages are: modified graphene 0.05wt.%, copper 0.9wt.%, carbon 0.7wt.%, iron 1.8wt.% , silicon carbide 1.0wt.%, lanthanum oxide 0.5wt.%, surfactant 2.4wt.%, and the balance is aluminum.

[0033] A preparation method for modified graphene-reinforced aluminum-based composite material, comprising the following steps:

[0034] (1) Graphene is added in dehydrated alcohol, m / v is 1:18, is placed in ball mill, after dispersing evenly, adds cationic surfactant, sonication 3 hours;

[0035] (2) Place the system after the ultrasonic treatment in step (1) in an oven at 45° C., remove absolute ethanol, and obtain modified graphene;

[0036] (3) Melt pure aluminum, add modified graphene when it is half melted, and keep it warm for 40 minutes at 710°C;

[0037] (4) After adding copper, carbon, iron, silicon carbide and lanthanum oxide, keep warm and stir eve...

Embodiment 3

[0042] A modified graphene-reinforced aluminum-based composite material, comprising the following components, the mass fraction percent of which is: modified graphene 0.1wt.%, copper 1.4wt.%, carbon 1.1wt.%, iron 2.9wt.% , silicon carbide 1.2wt.%, lanthanum oxide 1.2wt.%, surfactant 3.2wt.%, and the balance is aluminum.

[0043] A preparation method for modified graphene-reinforced aluminum-based composite material, comprising the following steps:

[0044] (1) Graphene is added in dehydrated alcohol, m / v is 1:21, is placed in ball mill, after dispersing evenly, adds cationic surfactant, sonication 3 hours;

[0045] (2) Place the system after the ultrasonic treatment in step (1) in an oven at 50° C., remove absolute ethanol, and obtain modified graphene;

[0046] (3) Melt pure aluminum, add modified graphene when it is half melted, and keep it warm for 55 minutes at 725°C;

[0047] (4) After adding copper, carbon, iron, silicon carbide and lanthanum oxide, keep warm and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com