Method for manufacturing high-strength steel through hot rolling and on-line thermal treatment

A high-strength steel and hot-rolled plate technology, applied in the field of hot-rolled direct quenching and two-phase zone annealing, can solve the problems of continuous casting and rolling difficulties, high economic costs, and low production efficiency, and achieve broad research and application prospects, The effect of simple production process and simple alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

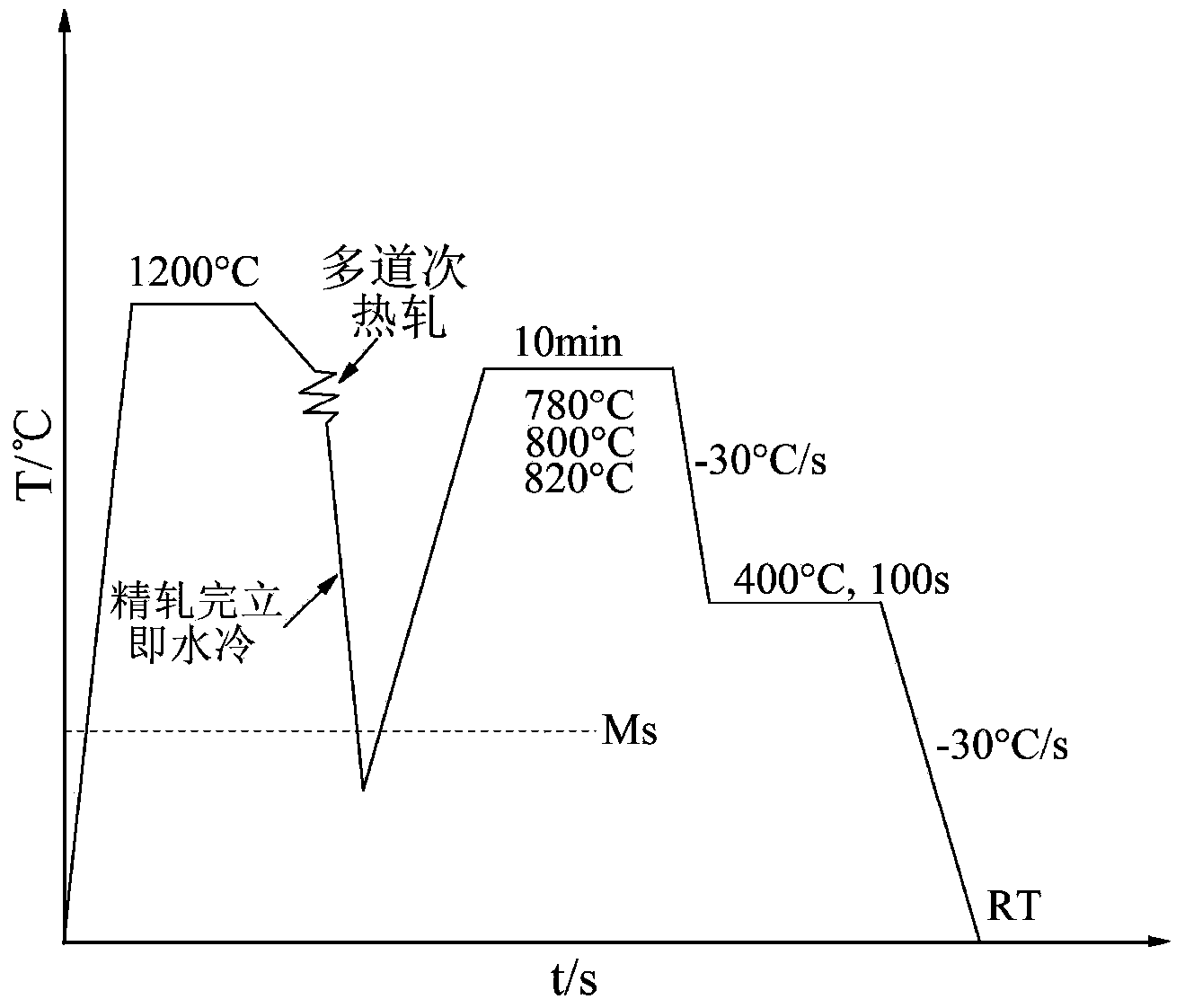

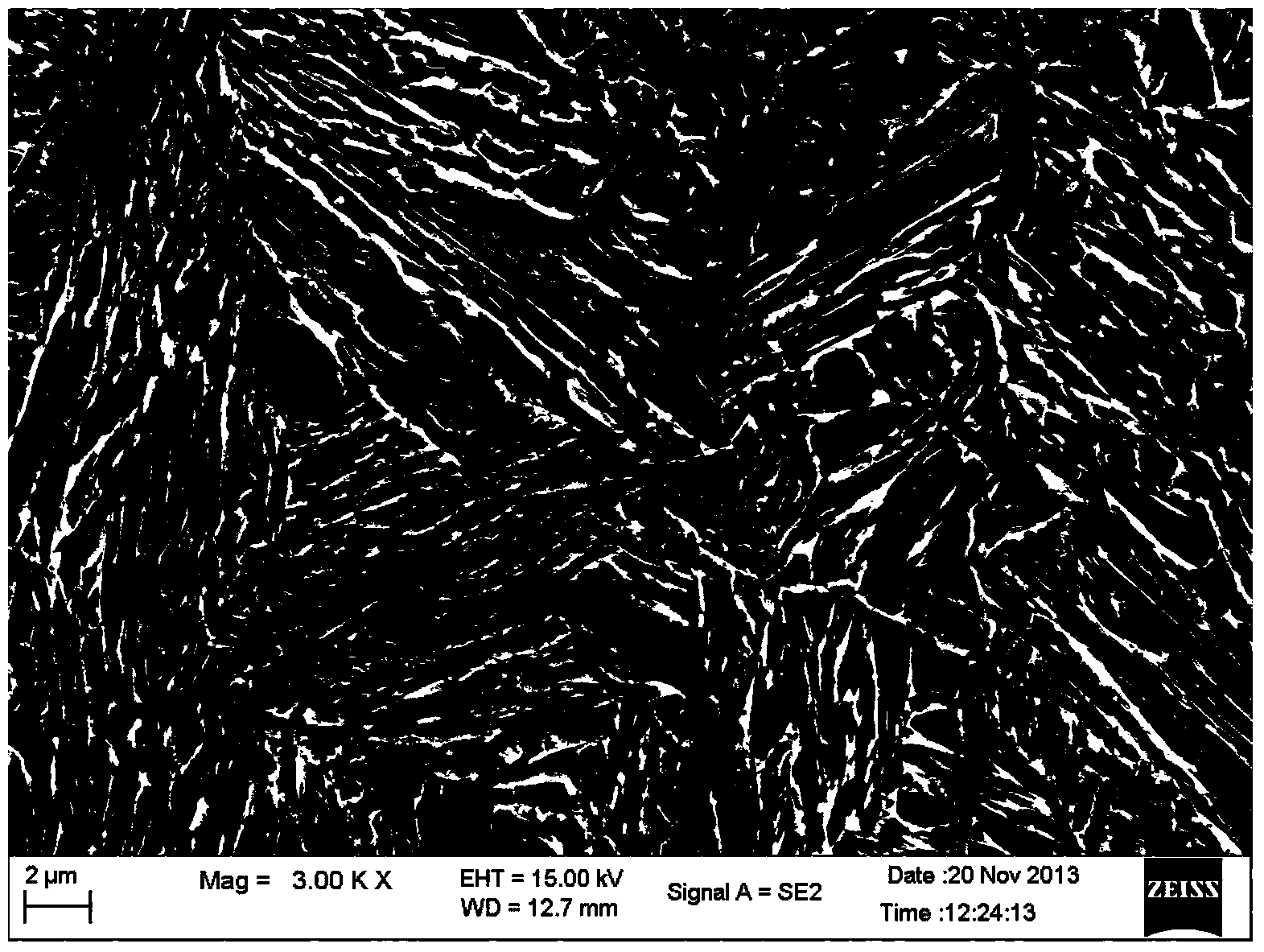

[0020] The cast slab with the composition shown in Table 1 was heated to 1200°C for heat preservation, followed by multi-pass hot rolling, and the final rolling temperature was 870°C. Immediately thereafter on the laminar flow cooling device, the rapid quenching treatment is cooled to below the Ms point), and a complete martensitic structure is obtained, and the photo of the structure is as attached figure 2 shown.

[0021] Table 1 is the mass percentage of the experimental steel composition

[0022] Table 1 Experimental steel composition / wt%

[0023] Numbering

C

Si

mn

S

P

Al

margin

1

0.28

1.87

2.0

0.0035

0.009

0.010

Fe and unavoidable impurities

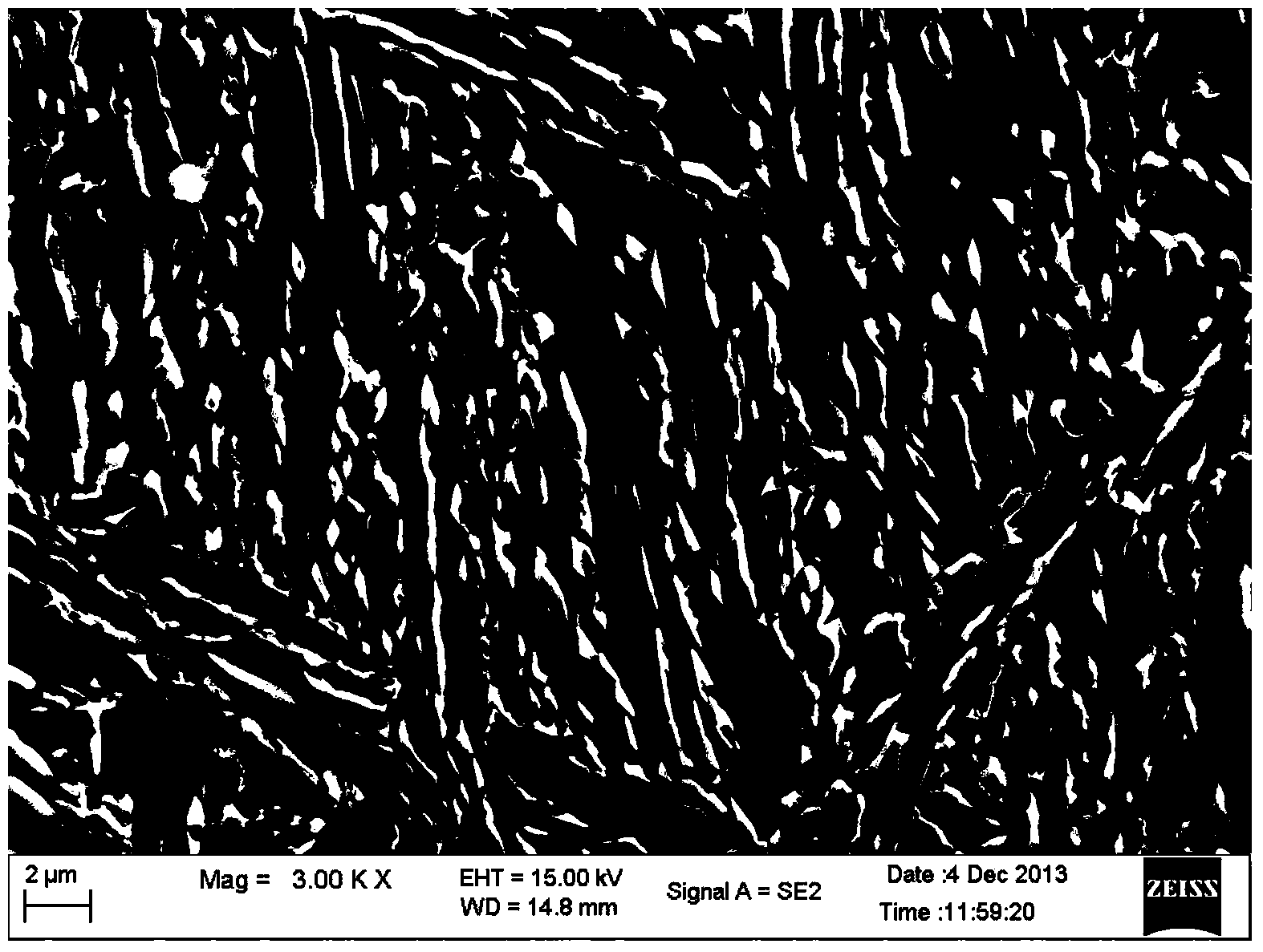

[0024] Subsequently, the quenched hot-rolled sheet was continuously annealed at 780°C, 800°C, and 820°C. After holding for 10 minutes, it was cooled to 400°C at a cooling rate of 30°C / s and held for 100s, and then rapidly cooled to room temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com