Normalized extra-thick plate with high strength and toughness and thickness of 150mm and method for manufacturing normalized extra-thick plate

A high-strength toughness and production method technology, which is applied in normalizing high-strength toughness 150mm extra-thick plate and its production field, can solve the problems of insufficient strength and poor low-temperature impact of extra-thick plates, and achieve small and stable mechanical property differences. The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A normalized high-strength toughness 150mm extra-thick plate, slab smelting, slab casting (slab specification-thickness×width×length: 400mm×2400mm×4100mm), steel plate rolling (rolling Manufacturing specifications - thickness × width: 150mm × 2500mm × 10000mm) and normalizing + weak water cooling treatment.

[0031] Its chemical composition (wt%) is as shown in table 2:

[0032] Table 2 Billet chemical composition (wt%)

[0033] C

Si

mn

P

S

Alt

Ni

Cu

V

Nb

Ti

CEQ

0.18

0.33

1.55

0.010

0.003

0.032

0.32

0.20

0.048

0.042

0.016

0.48

[0034] In the slab casting project, the casting speed range is 0.75m / min, and the slab center segregation C class is 0.5.

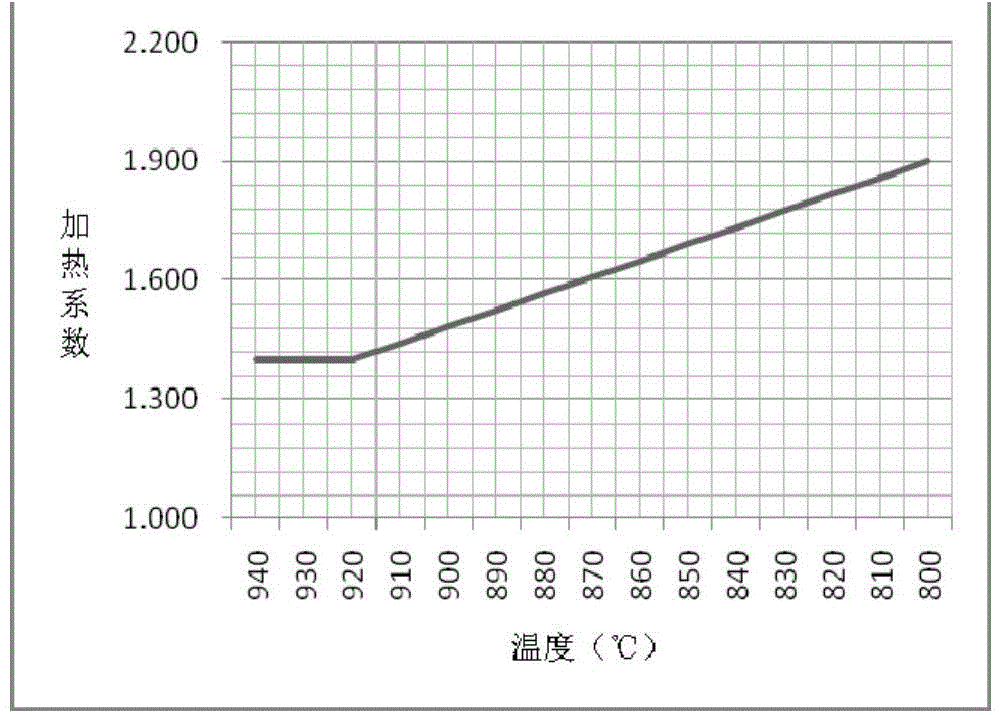

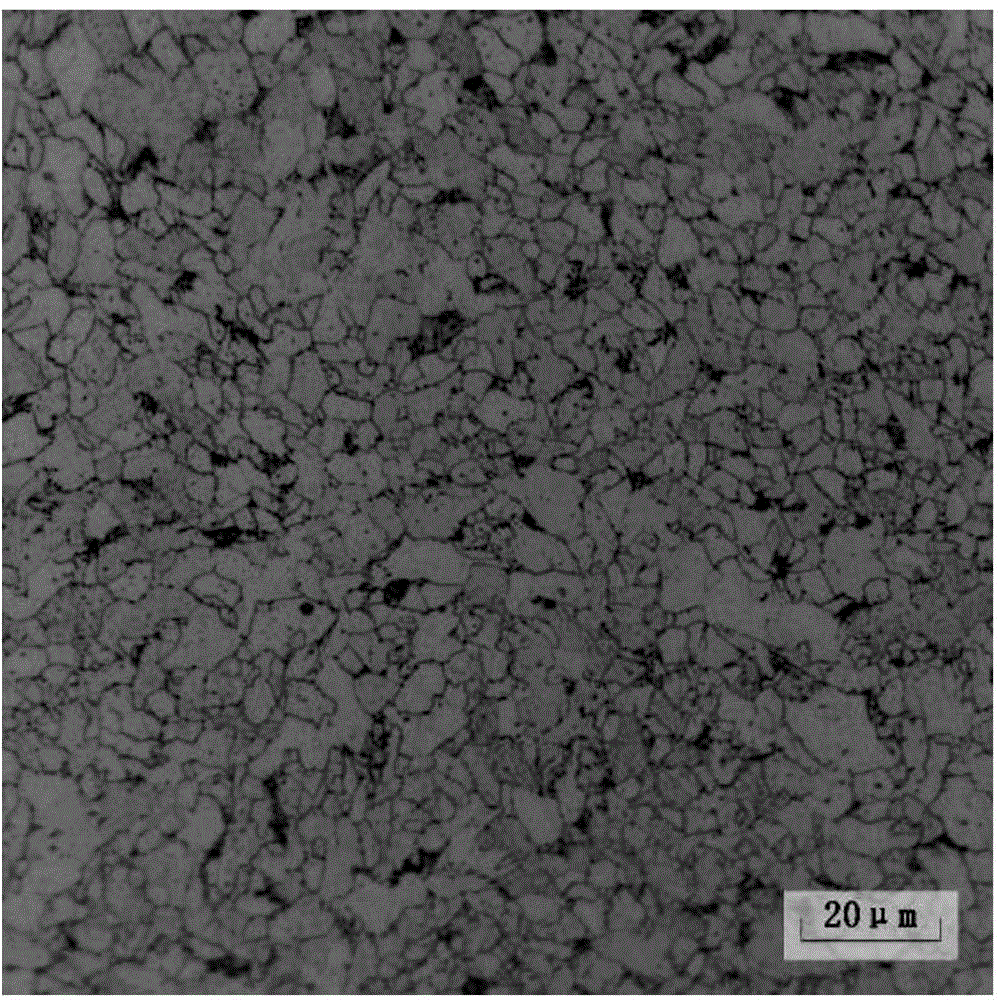

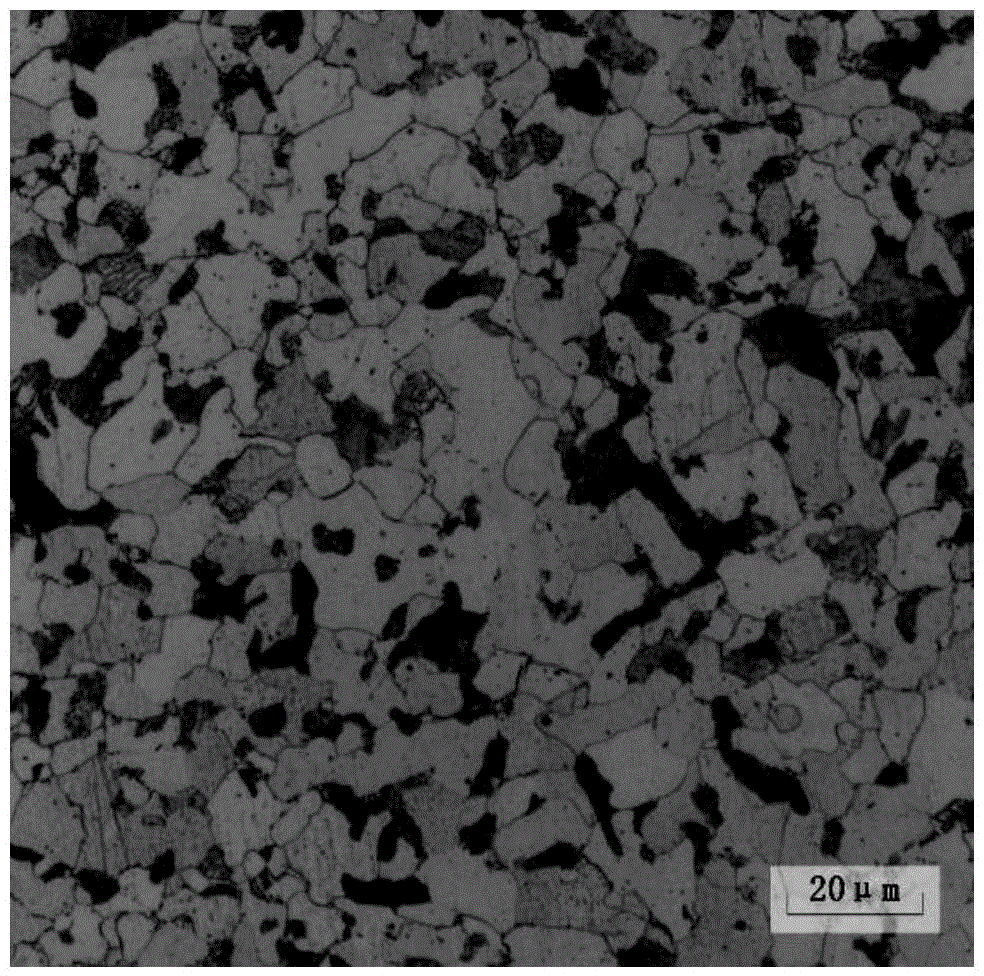

[0035]The rolling process parameter setting and heat treatment process control process parameters are shown in Table 3 and Table 4. During the normalizing process, the normalizing temperature is 880°C. According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com