Cast rolling H-shaped steel cooling device

A cooling device, H-beam technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of difficult H-beam section cooling and other problems, and achieve the effect of excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

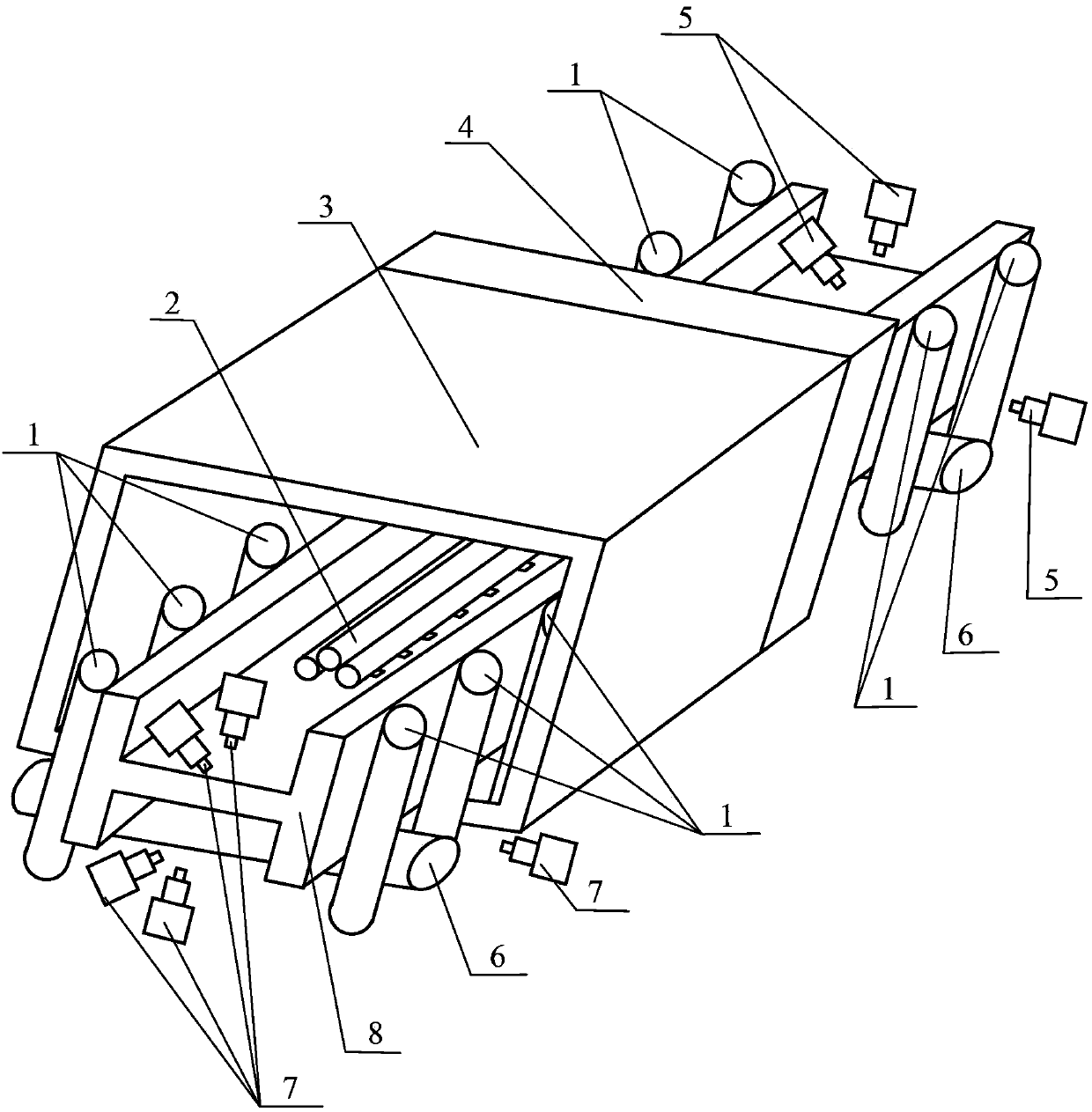

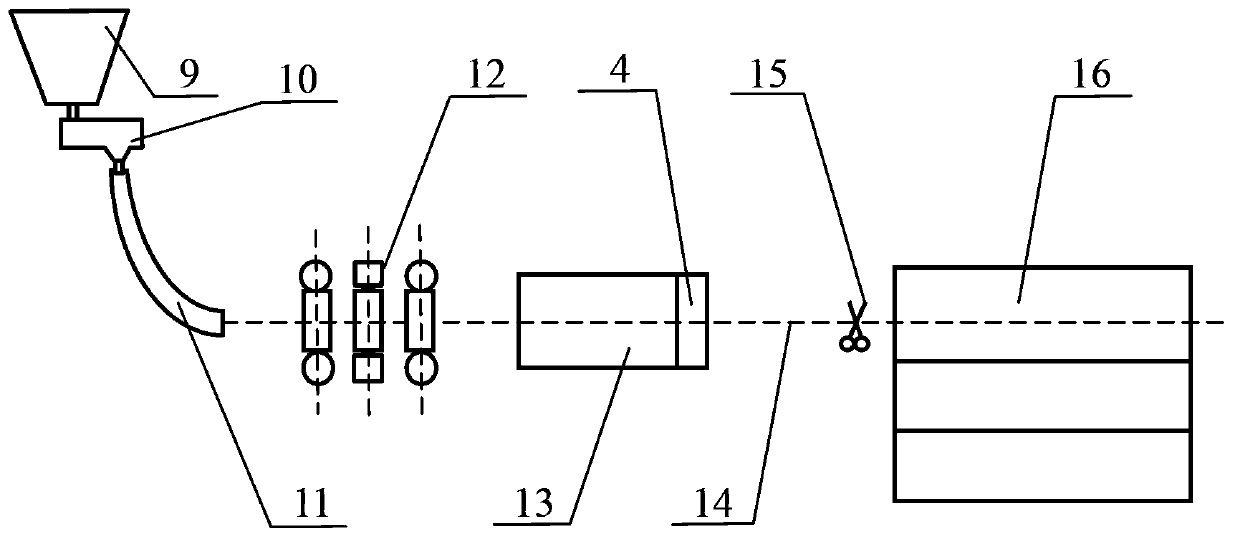

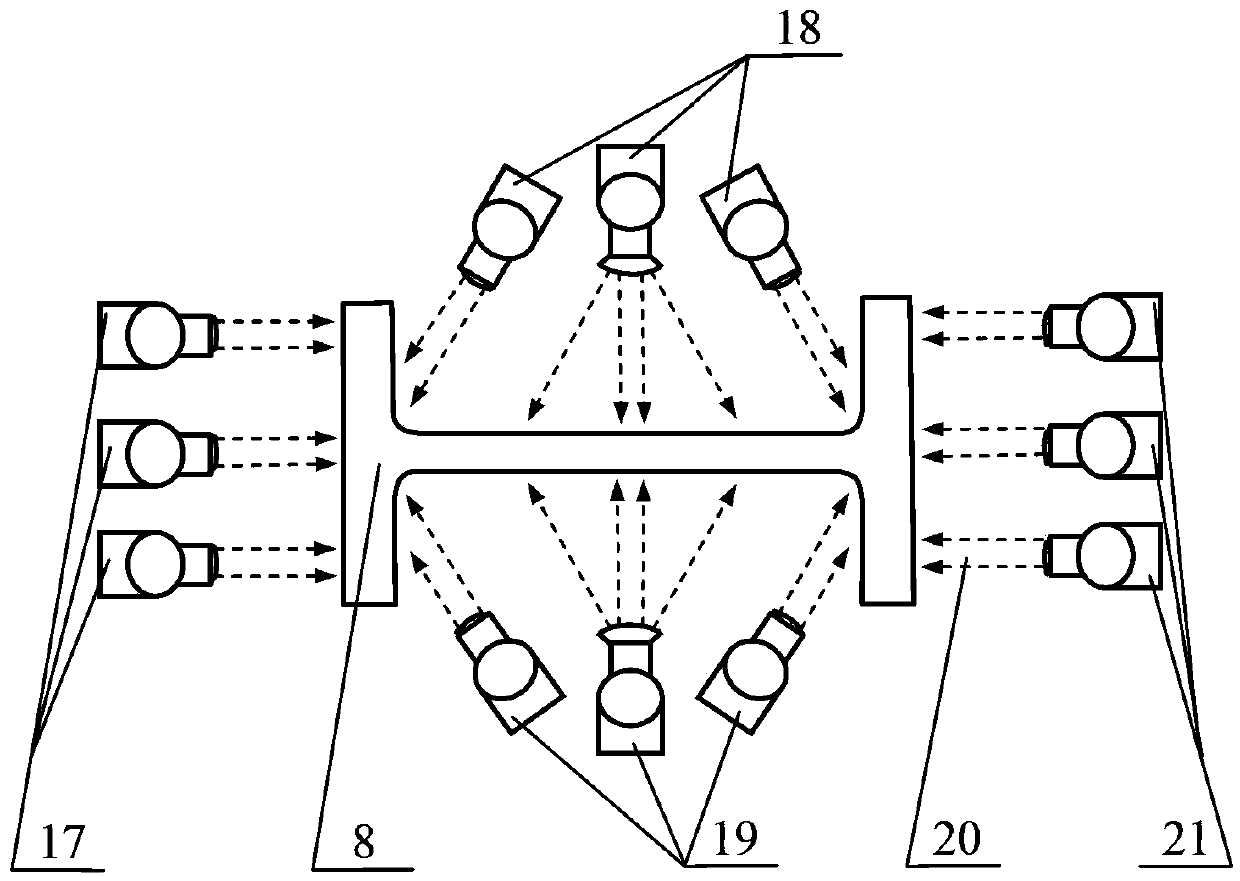

[0028] Such as figure 1 As shown, this preferred embodiment includes a housing 3 , a conveying roller table 6 , a restraining roller table 1 , a thermometer group 7 at the entrance of the housing 3 , a thermometer group 5 at the outlet of the housing 3 , and a wind baffle 4 . Such as image 3Shown, in housing 3, present preferred embodiment comprises left nozzle 17, right nozzle 21, upper nozzle 18, lower nozzle 19 and is arranged on each nozzle and extends along the multiple groups of nozzle length direction Nozzle (unmarked). Such as Figure 5 As shown, the preferred embodiment includes a left air supply pipe 27, an upper air supply pipe 28, a lower air supply pipe 29, a right air supply pipe 30 and a plurality of nozzles respectively arranged on each air supply pipe.

[0029] Among them, another example figure 1 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com