Low temperature impact resistant polycarbonate/ABS (acrylonitrile, butadiene and styrene) resin plastic alloy

A technology of polycarbonate resin and ABS resin, which is applied in the field of polycarbonate/ABS resin plastic alloys, can solve the problems of low low-temperature impact strength, and achieve outstanding low-temperature impact resistance, excellent low-temperature impact strength, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

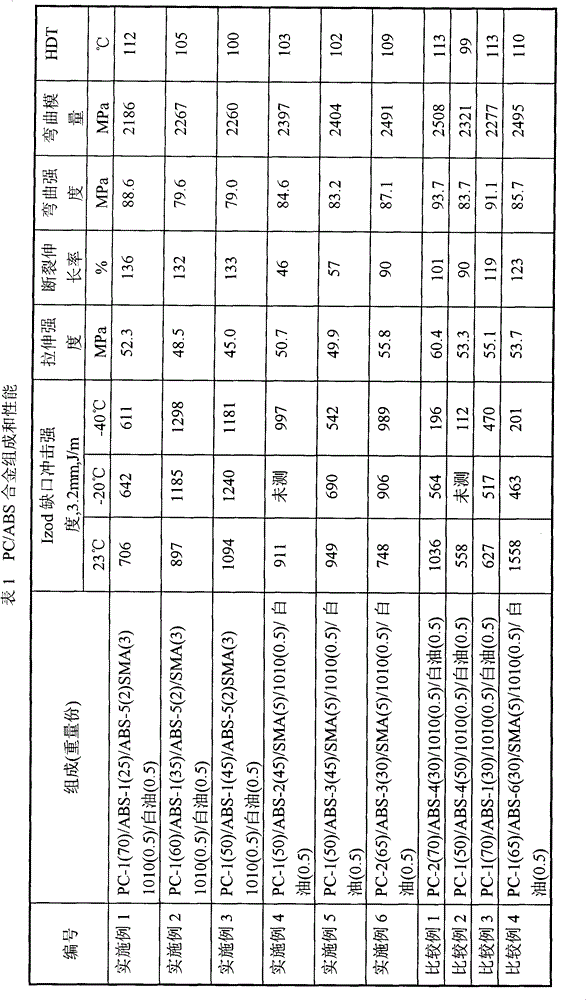

[0050] Weigh 3.500 kg of bisphenol A polycarbonate (PC-1) with a dried MFR (300°C, 1.2kg) of 7.0g / 10min, an MFR (220°C, 10kg) of 9.1g / 10min, and a rubber weight of 100 Content is 10%, 1.250 kilograms of bulk method ABS resin (ABS-1) of average rubber particle diameter 2.5 microns, rubber weight percent composition is 0.100 kilogram of emulsion polymerization method ABS resin (ABS-5) of 64%, MFR (230 ℃, 2.16kg) is 7g / 10min, maleic anhydride weight percent content is 0.150 kilogram of SMA resin of 18%, antioxidant 1010 25 grams, 12# white oil 25 grams, put into a container and use agitator Mix evenly, and then add to the feeder of the twin-screw extruder for later use. Twin-screw extruder (screw diameter 27mm, length / diameter ratio 36, Germany Leistritz company) barrel temperature is set in ten sections from the feed inlet to the extrusion outlet at 220°C, 240°C, 250°C, 255°C, 265°C , 270°C, 270°C, 265°C, 260°C, 255°C, when the temperature of each section reaches the set value,...

Embodiment 2

[0054]Weigh 3.000 kg of bisphenol A polycarbonate (PC-1) with a dried MFR (300°C, 1.2kg) of 7.0g / 10min, an MFR (220°C, 10kg) of 9.1g / 10min, and a rubber weight of 100 Content is 10%, 1.750 kilograms of bulk method ABS resin (ABS-1) of average rubber particle diameter 2.5 microns, rubber weight percent composition is 0.100 kilogram of emulsion polymerization method ABS resin (ABS-5) of 64%, MFR (230 ℃, 2.16kg) is 7g / 10min, maleic anhydride weight percent content is 0.150 kilogram of SMA resin of 18%, antioxidant 1010 25 grams, 12# white oil 25 grams, put into a container and use agitator Mix evenly, then add in the twin-screw extruder feeder and prepare PC / ABS alloy, injection molded sample bar, test performance by the same conditions of Example 1, the results are shown in Table 1.

Embodiment 3

[0056] Weigh 2.500 kg of bisphenol A polycarbonate (PC-1) with a dried MFR (300°C, 1.2kg) of 7.0g / 10min, an MFR (220°C, 10kg) of 9.1g / 10min, and a rubber weight of 100 Content is 10%, 2.250 kilograms of bulk method ABS resin (ABS-1) of average rubber particle diameter 2.5 microns, rubber weight percent composition is 0.100 kilogram of emulsion polymerization method ABS resin (ABS-5) of 64%, MFR (230 ℃, 2.16kg) is 7g / 10min, maleic anhydride weight percent content is 0.150 kilogram of SMA resin of 18%, antioxidant 1010 25 grams, 12# white oil 25 grams, put into a container and use agitator Mix evenly, then add in the twin-screw extruder feeder and prepare PC / ABS alloy, injection molded sample bar, test performance by the same conditions of Example 1, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com