Cold-resisting halogen-free inflaming retarding ABS (Acrylonitrile Butadiene Styrene) and preparation method thereof

An ABS material and cold-resistant technology, which is applied in the field of cold-resistant halogen-free flame-retardant ABS and its preparation, can solve the problems of high corrosion, large smoke generation, and non-environmental protection, and achieve high impact strength and excellent flame-retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of cold-resistant halogen-free flame-retardant ABS material, comprising the following steps:

[0032] 1) Mix all kinds of raw materials evenly;

[0033] 2) Melt and extrude the uniformly mixed raw materials, water cool and pelletize.

[0034] The temperature of melt extrusion is 180-200°C.

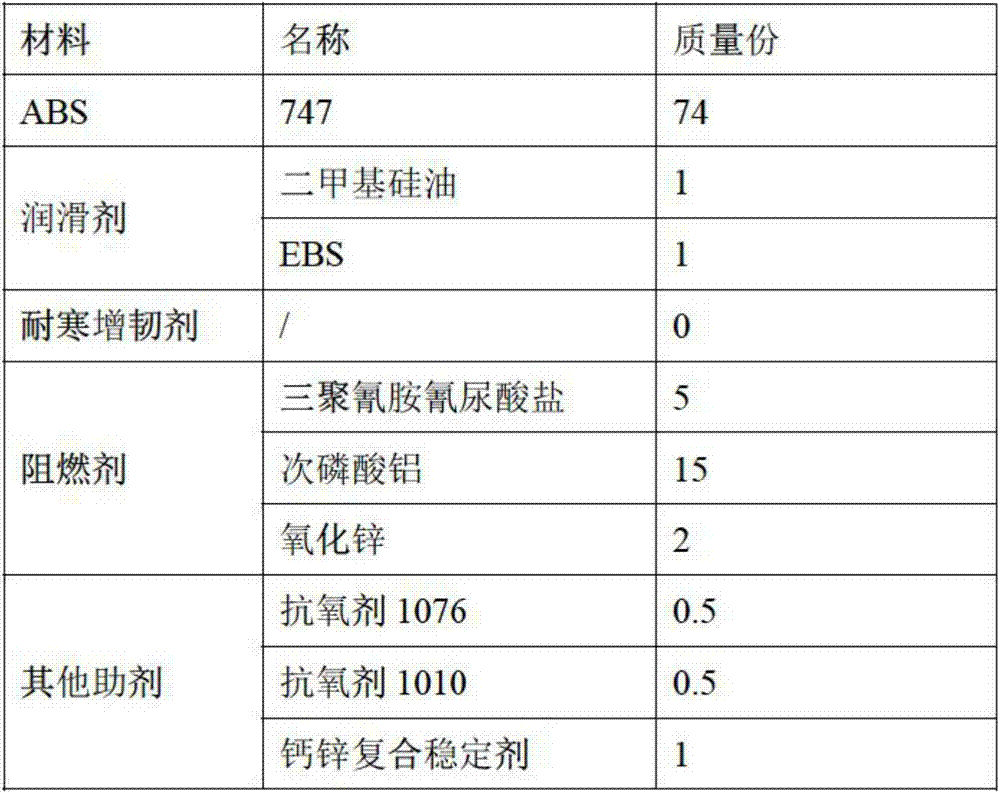

Embodiment 1

[0037] The formula composition of the present embodiment is as follows:

[0038] The formula of table 1 embodiment 1

[0039]

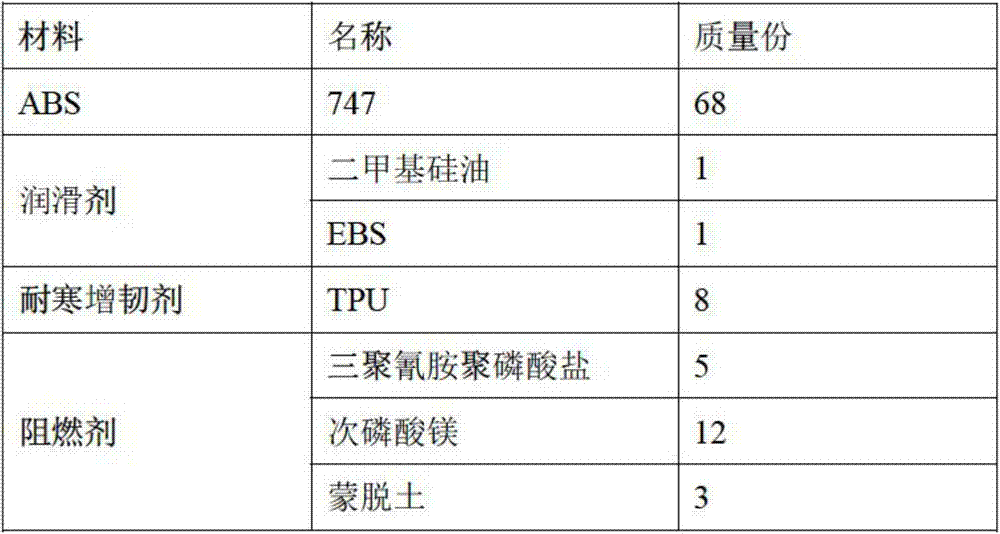

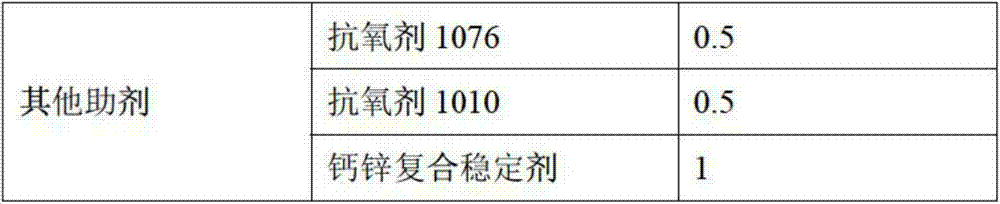

Embodiment 2

[0041] The formula composition of the present embodiment is as follows:

[0042] The formula of table 2 embodiment 2

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com