ABS composite resistant to high and low temperatures and chemicals and preparation method of ABS composite

A chemical resistance, high and low temperature resistance technology, applied in the field of ABS composite materials and its preparation, to achieve excellent comprehensive performance, easy large-scale industrial production, and improve the effect of solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the above-mentioned high and low temperature resistant and chemical resistant ABS composite material comprises the following steps: After drying each raw material, add it to a high-speed mixer and mix evenly, then transfer it to a twin-screw extruder, extrude, cool, granulate, and dry, Obtain high and low temperature resistant, chemical resistant ABS composite materials.

[0040] Preferably, the temperature of each temperature zone of the twin-screw extruder is between 180-230° C., the feeding speed is 12-24 r / min, and the main engine speed is 250-350 r / min.

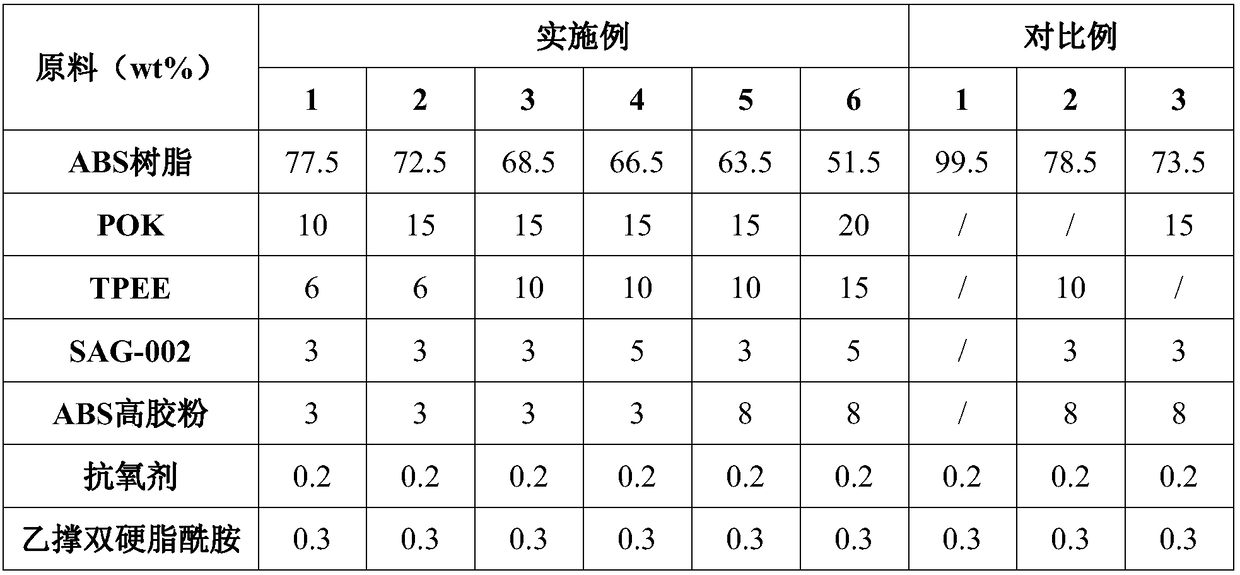

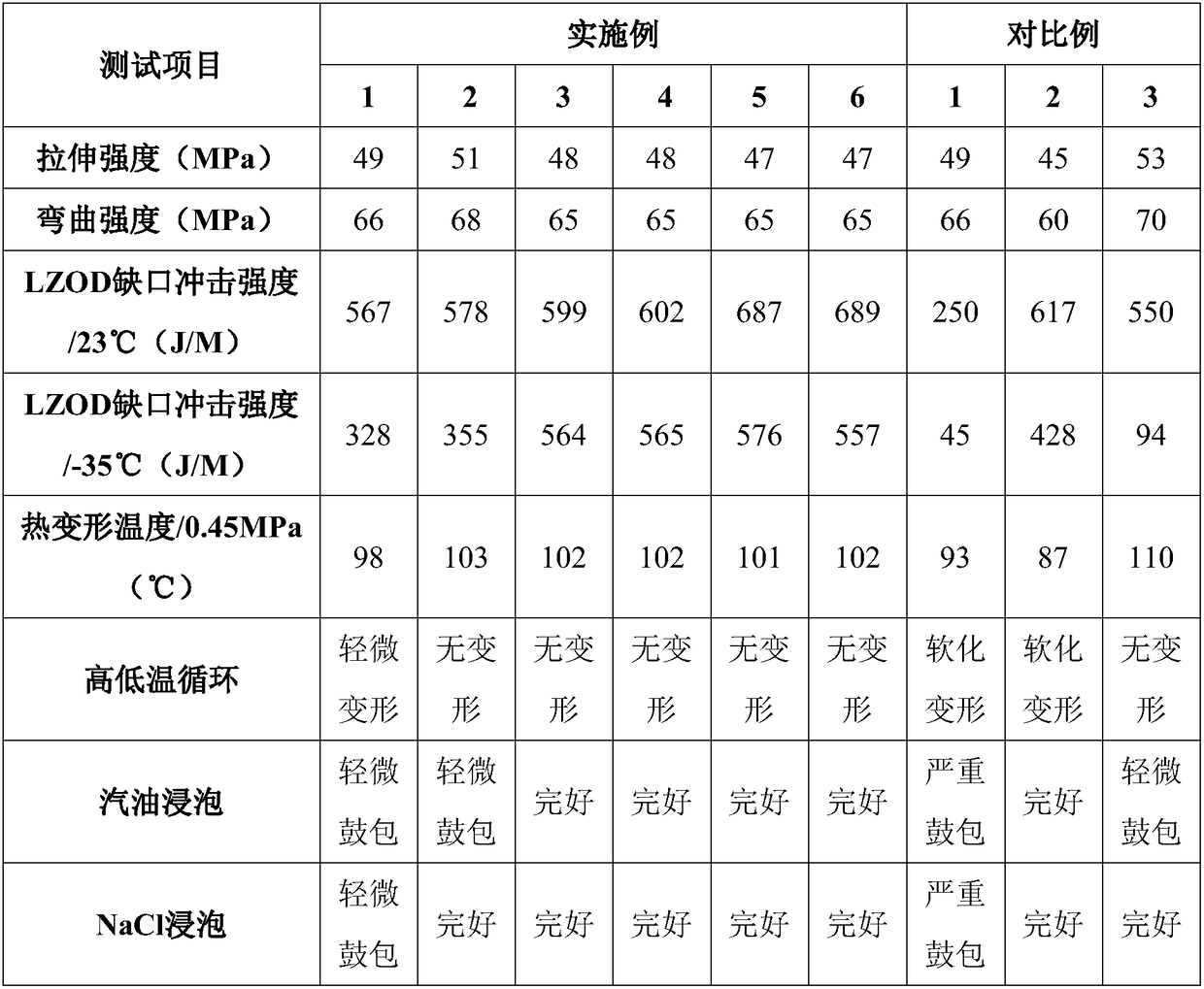

Embodiment 1~6 and comparative example 1~3

[0043] The composition of the raw materials of the ABS composite materials prepared in Examples 1 to 6 and Comparative Examples 1 to 3 is shown in Table 1, and the preparation method is as follows: dry each raw material at 80°C for 3 hours, then add it to a high-speed mixer, and adjust the speed of the mixer to 500r / min, stirred for 5 min, then transferred to a twin-screw extruder, extruded, cooled, granulated, and dried to obtain an ABS composite material.

[0044] Dry the ABS composite material first, then injection molding (injection molding process conditions: nozzle temperature is 240°C, temperature in each zone is 240°C, 235°C, 230°C, pressure holding time is 2-4s, injection pressure is 40- 60MPa.) is the standard test sample, and the performance test is carried out, and the test results are shown in Table 2.

[0045] The raw material composition table of the ABS composite material of table 1 embodiment 1~6 and comparative examples 1~3

[0046]

[0047] Note:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com