Polypropylene-calcium carbonate filling master batch and preparation method thereof

A technology for filling master batch and calcium carbonate, applied in the field of plastic processing, can solve the problems of single improvement of material rigidity or toughness, increased cost, complicated preparation process, etc., and achieves the effects of simple method, increased load deformation temperature, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

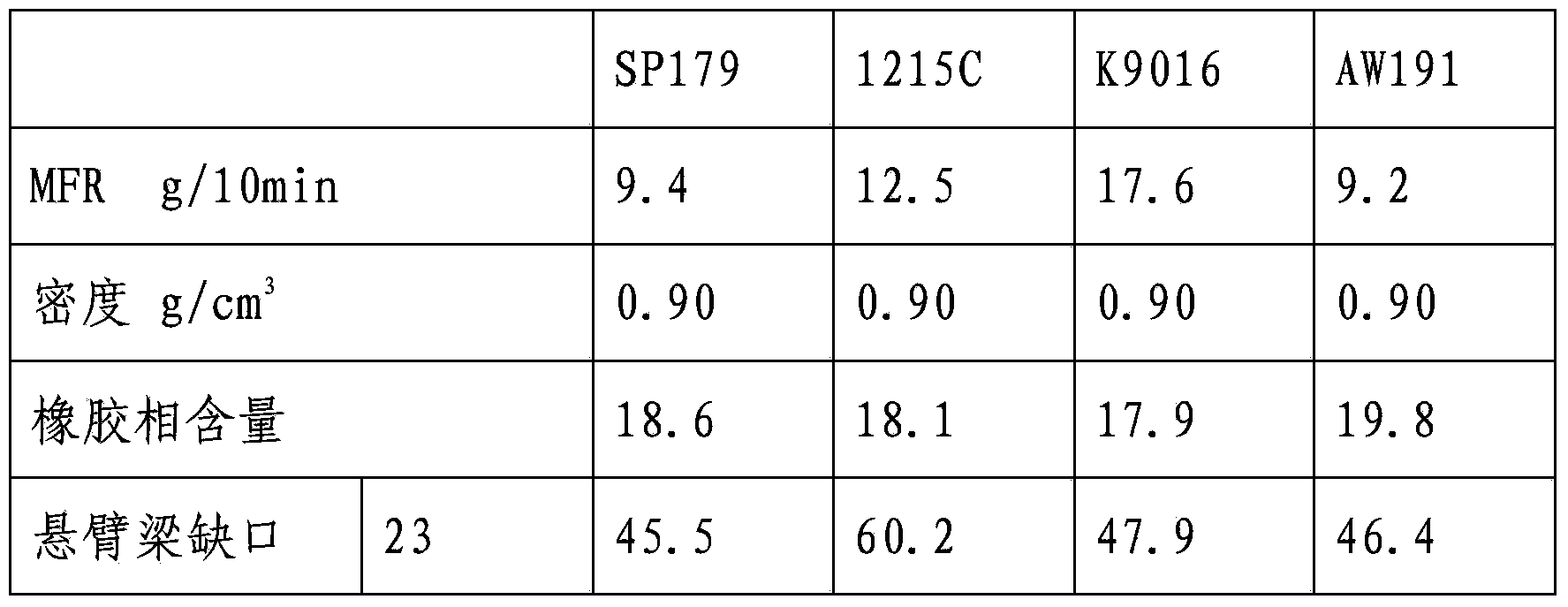

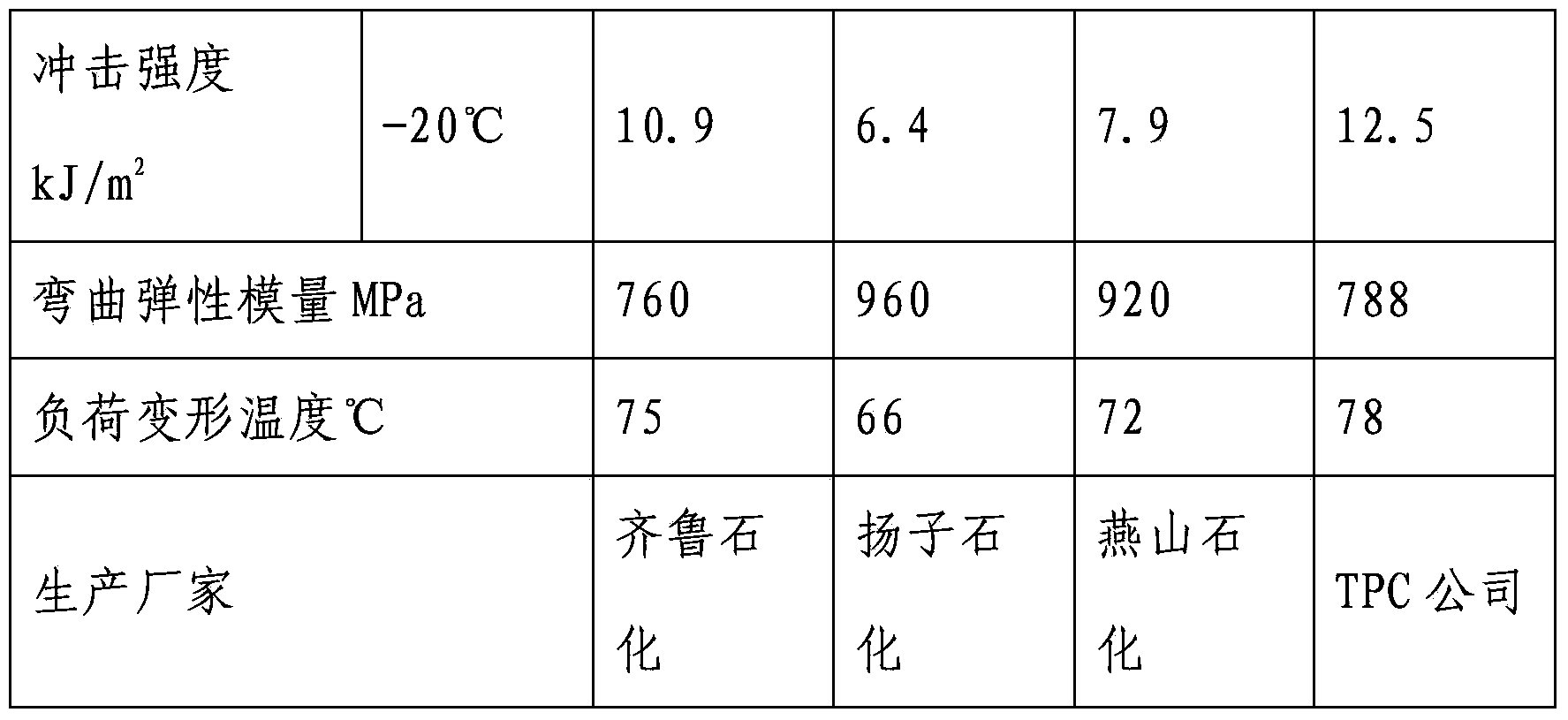

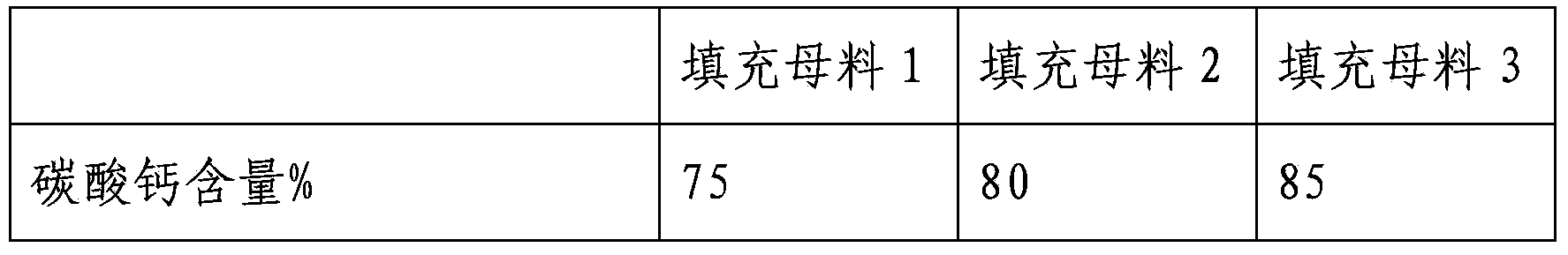

[0029] The preparation process of filler masterbatch 1-3 is as follows: first, fully dry the calcium carbonate in a dryer at 120°C to remove moisture, then put it into a high-speed mixer at 120°C, and mix NXT-101 with a weight of 1% of the weight of calcium carbonate Add twice, stir at high speed for 5-10 minutes, then add stearic acid rare earth coupling agent with a weight of 1% of the calcium carbonate weight, stir again at high speed for 5 minutes to obtain surface-activated calcium carbonate, and then add polypropylene with high rubber phase content , mixed evenly, extruded and granulated by a twin-screw extruder to obtain a filling masterbatch.

[0030] The composition and content of filler masterbatch 1-3 are:

[0031] Filler masterbatch 1: SP179, 25 parts by weight, calcium carbonate, 75 parts by weight. Coupling agent for calcium carbonate surface treatment: NXT-101, 7.5 parts by weight; rare earth stearate, 7.5 parts by weight.

[0032] Filler masterbatch 2: SP179,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com