Rectangle ice box frame and producing method thereof

A freezer and box frame technology, which is applied to the horizontal rectangular freezer box frame and its manufacturing field, can solve the problems of low impact strength, poor appearance performance of the box frame, easy cracking mold investment costs, etc., and achieves high impact strength at low temperature. , Beautiful appearance, the effect of improving the resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

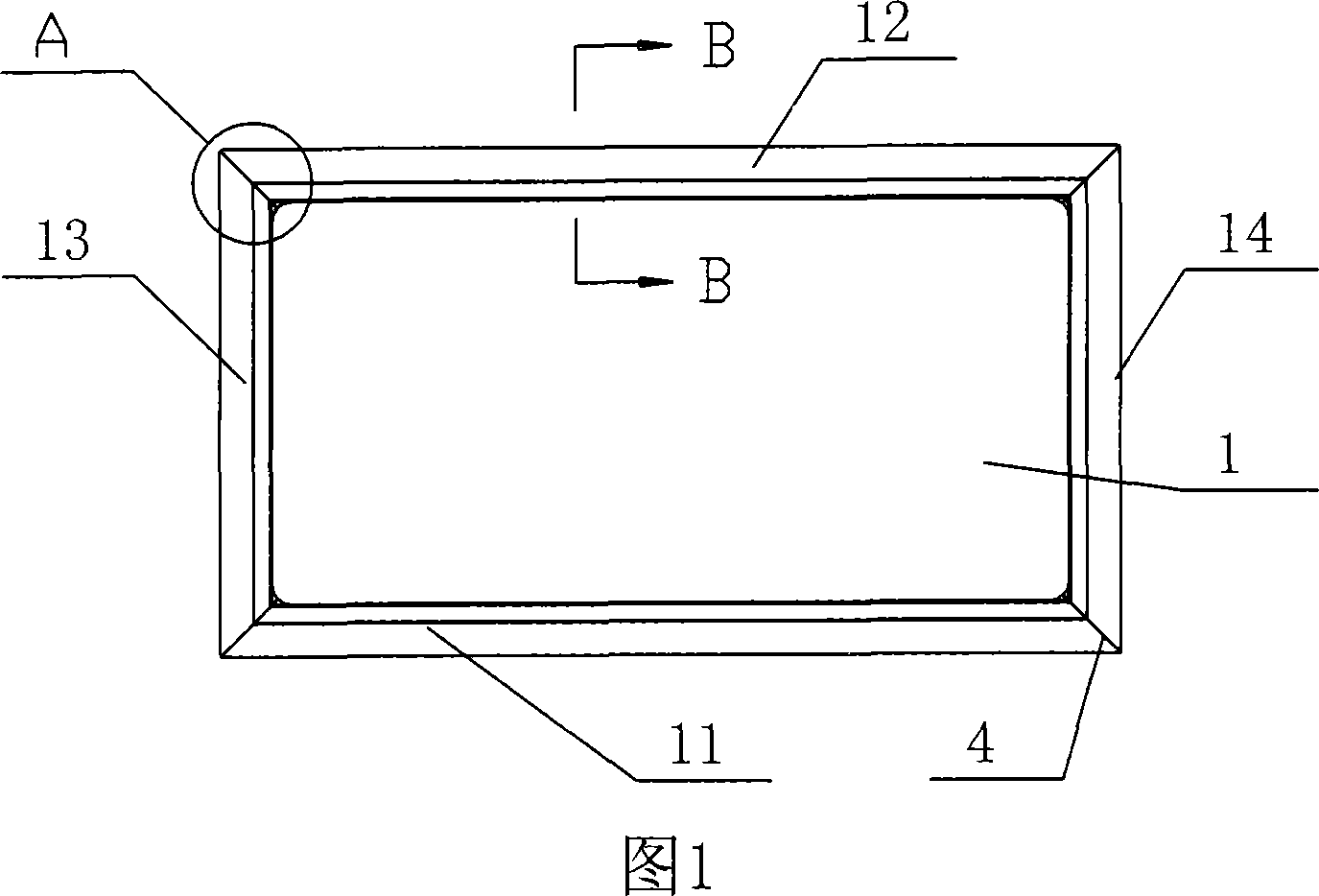

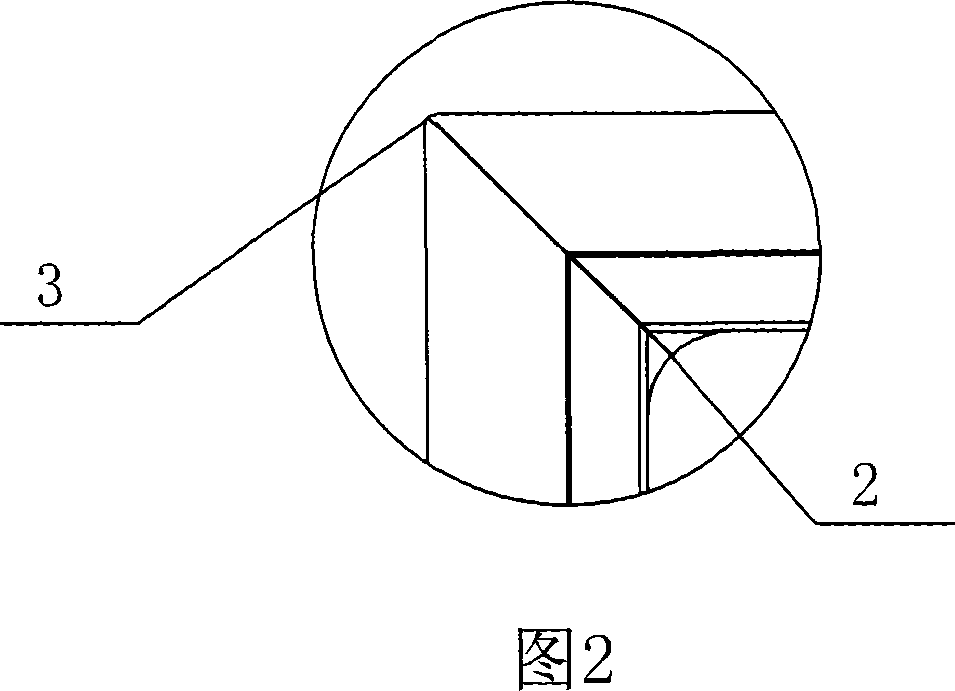

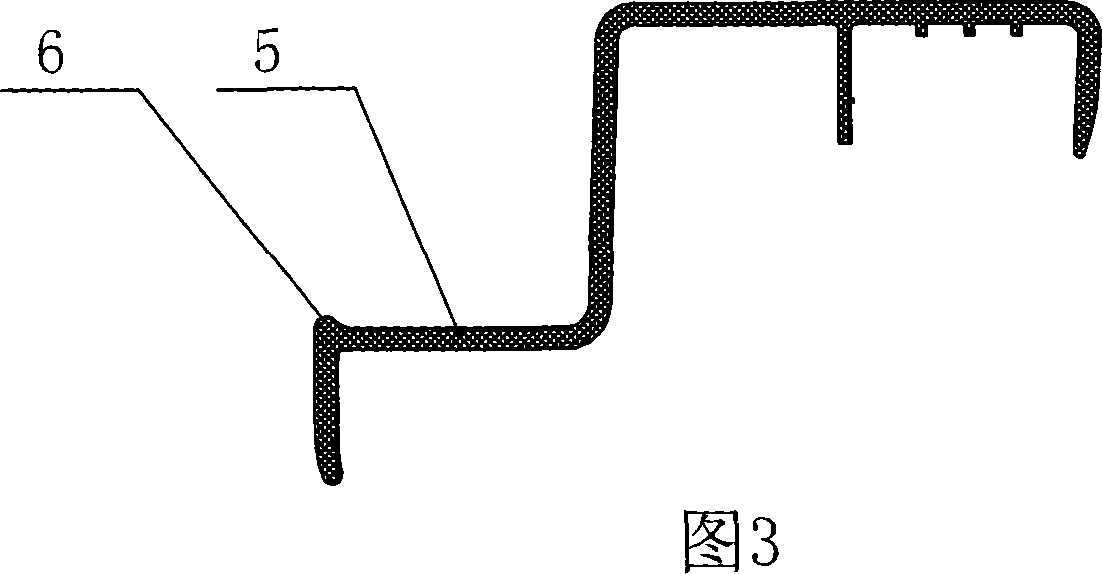

[0026] As shown in Figures 1 to 3, a rectangular refrigerator box frame includes a frame body 1 composed of a front frame bar 11, a rear frame bar 12, a left frame bar 13 and a right frame bar 14. The front frame bar 11, The rear frame strip 12, the left frame strip 13 and the right frame strip 14 are four plastic extruded strips with the same cross-section. The two ends of each extruded strip are provided with bevels 4, and the four extruded strips pass through the two ends of the extruded strip. The position of the bevel 4 is butt-jointed to form a frame body 1 after being welded. The extruded strip is made of plastic material HPVC. The radius is 25 mm and the outer corner 3 has a radius of 4 mm. The front frame bar 11, the rear frame bar 12, the left frame bar 13 and the right frame bar 14 are all provided with a step surface 5, and the edge of the step surface 5 is provided with a protruding rib 6, the rib bar The height of 6 is 1 millimeter, and this rib 6 is used as the...

Embodiment 2

[0030] The structure and manufacturing method of this embodiment are basically the same as those of Embodiment 1. The structural differences are: as shown in Figures 4 to 6, the front frame bar 11, the rear frame bar 12, the left frame bar 13 and the right frame bar 14 There are three steps on the upper surface, and a protruding rib 6 is provided at the edge of each step, and the rib 6 is used as a guide bar for the glass door with a built-in plastic frame to facilitate the sliding of the glass door frame.

[0031] The difference in its manufacturing method is that extruding an extruded strip with exactly the same cross-section and three stepped surfaces on the cross-section through an extrusion die, with ribs 6 protruding from the edge of each stepped surface, and the ribs 6 The height is 1 mm, and the rib 6 is a guide bar for the glass door with a built-in plastic frame, so as to facilitate the sliding of the glass door.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com