Toughened antibacterial polypropylene pressure pipe

An antibacterial polypropylene, pressure pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of no antibacterial and bacteriostatic function, easy to breed bacteria, and insignificant effect, and achieve excellent hygienic performance. , Not easy to brittle crack, high heat distortion temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

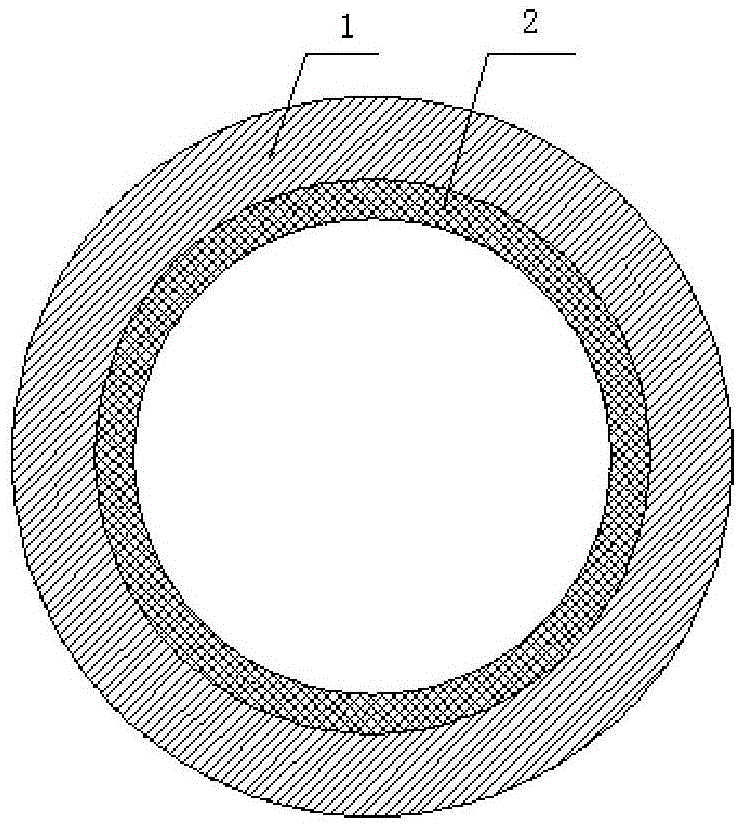

[0026] A toughened antibacterial polypropylene pressure pipe, the toughening layer formula: 95 kg of random copolymerized polypropylene PA14D, 0.1 kg of beta nucleating agent TMP-5, 5 kg of maleic anhydride grafted polypropylene, 0.1 kg of heat stabilizer 1010, mixed uniformly in a high mixer, and then melted and extruded to granulate through a twin-screw extruder. Antibacterial layer formula: 90 kg of random copolymerized polypropylene PA14D, 5 kg of maleic anhydride grafted polypropylene, 5 kg of inorganic nano-antibacterial agent, mixed evenly in a high-mixer, and melted and extruded to granulate through a twin-screw extruder. The production of the pressure pipe is to put the modified inner and outer layer materials into their respective single-screw extruders for extrusion production, two-layer composite co-extrusion mold, cooling, pulling, cutting, and then the finished product is obtained.

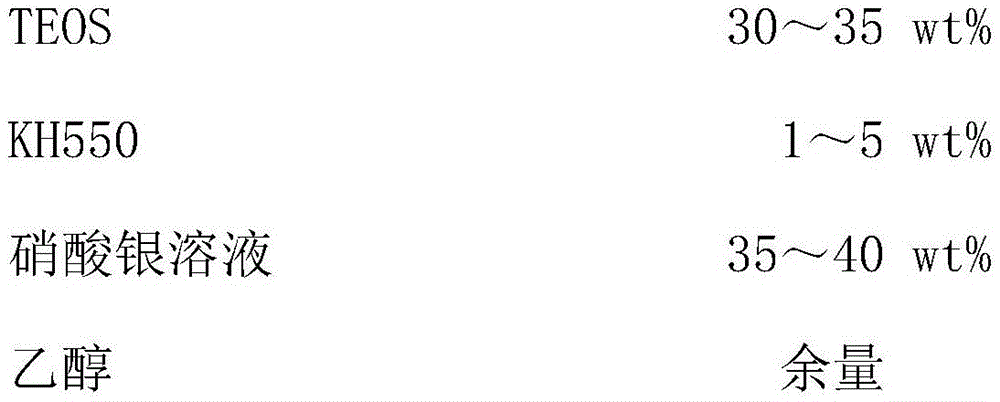

[0027] The preparation method of the described inorganic nano antibacterial agen...

Embodiment 2

[0032] A toughened antibacterial polypropylene pressure pipe, the toughening layer formula: 90 kg of random copolymerized polypropylene PA14D, 0.15 kg of beta nucleating agent TMP-5, 10 kg of maleic anhydride grafted polypropylene, 0.1 kg of heat stabilizer 1010, mixed uniformly in a high mixer, and then melted and extruded to granulate through a twin-screw extruder. Antibacterial layer formula: 84 kg of random copolymerized polypropylene PA14D, 8 kg of maleic anhydride grafted polypropylene, 8 kg of inorganic nano-antibacterial agent, mixed evenly in a high-mixer, melted and extruded to pelletize through a twin-screw extruder. The production of the pressure pipe is to put the modified inner and outer layer materials into their respective single-screw extruders for extrusion production, two-layer composite co-extrusion mold, cooling, pulling, cutting, and then the finished product is obtained.

[0033] The preparation method of the described inorganic nano antibacterial agent ...

Embodiment 3

[0038]A toughened antibacterial polypropylene pressure pipe, the toughening layer formula: 90 kg random copolymer polypropylene PA14D, 0.2 kg β nucleating agent TMP-5, 10 kg maleic anhydride grafted polypropylene, 0.1 kg heat stabilizer 1010, mixed uniformly in a high mixer, and then melted and extruded to granulate through a twin-screw extruder. Antibacterial layer formula: 84 kg of random copolymerized polypropylene PA14D, 8 kg of maleic anhydride grafted polypropylene, 8 kg of inorganic nano-antibacterial agent, mixed evenly in a high-mixer, melted and extruded to pelletize through a twin-screw extruder. The production of the pressure pipe is to put the modified inner and outer layer materials into their respective single-screw extruders for extrusion production, two-layer composite co-extrusion mold, cooling, pulling, cutting, and then the finished product is obtained.

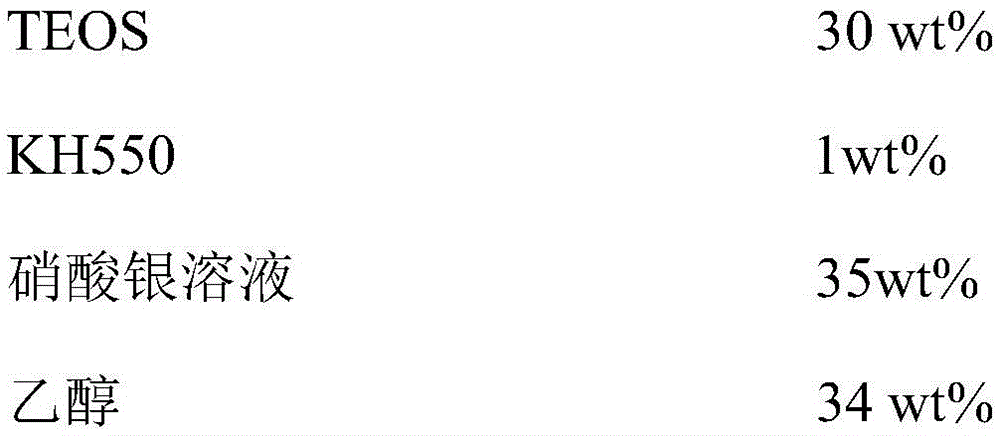

[0039] The preparation method of described inorganic nano antibacterial agent is to use tetraethylortho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com