Polypropylene composition for automobile enamel-plastic instrument panel frameworks and preparation method thereof

A technology of polypropylene composition and instrument panel, which is applied in the field of polypropylene composition and its preparation, can solve the problems of complex production process, high technical cost, increased cost, etc., achieve high surface activity, reduce manufacturing cost, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

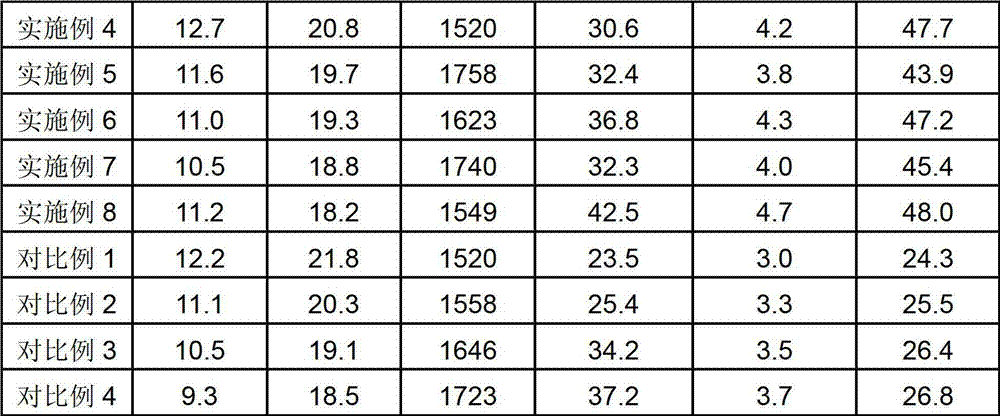

Examples

Embodiment 1

[0042] The main components of the polypropylene composition of the present invention include 80.7% M700R, 10% inorganic filler, 6% toughening agent POE, 1% maleic anhydride grafted polypropylene (PP-g-MAH), 1% ethylene ethyl acrylate ( EEA), 0.1% antioxidant 3114, 0.2% antioxidant 168 and 1% black masterbatch.

Embodiment 2

[0044] The main components of the polypropylene composition of the present invention include 76.7% M700R, 10% inorganic filler, 6% toughening agent POE, 3% maleic anhydride grafted polypropylene (PP-g-MAH), 3% ethylene ethyl acrylate ( EEA), 0.1% antioxidant 3114, 0.2% antioxidant 168 and 1% black masterbatch.

Embodiment 3

[0046] The main components of the polypropylene composition of the present invention include 70.7% M700R, 15% inorganic filler, 8% toughening agent POE, 3% maleic anhydride grafted polypropylene (PP-g-MAH), 2% ethylene ethyl acrylate ( EEA), 0.1% antioxidant 3114, 0.2% antioxidant 168 and 1% black masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com