Thermosetting resin composite and cured resin

A resin composition, thermosetting technology, applied in the direction of coating non-metallic protective layer, printed circuit secondary treatment, etc., to achieve the effect of low-cost productivity and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

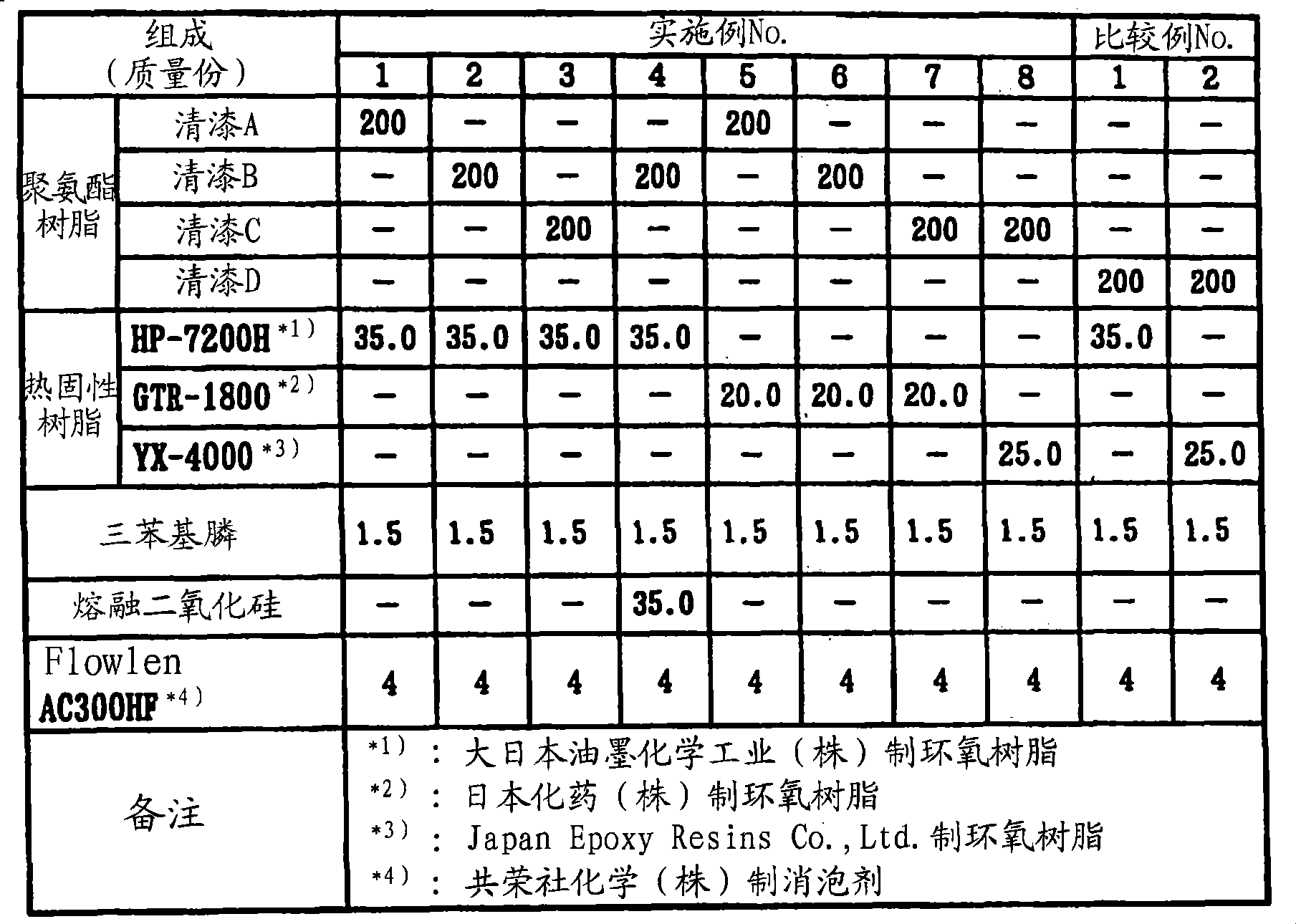

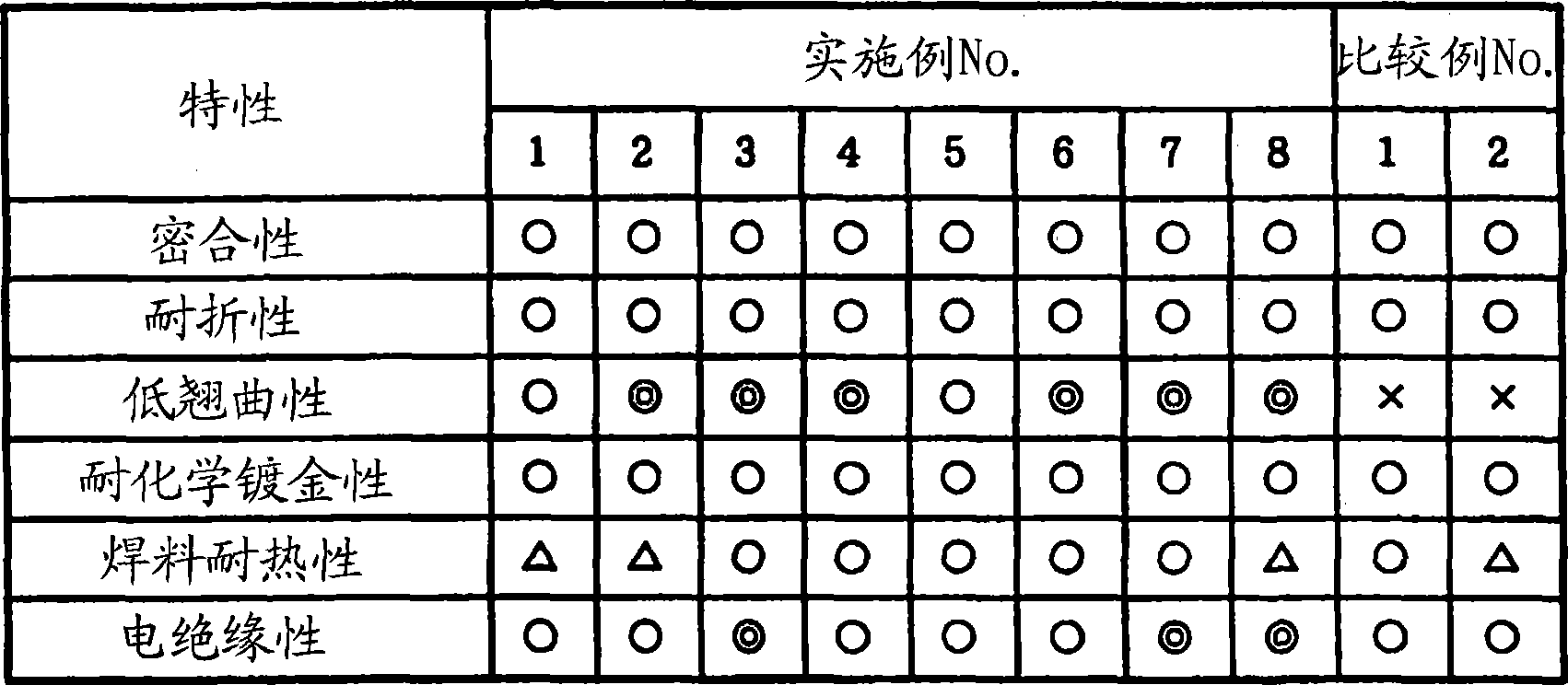

[0055] Examples and comparative examples are shown below to describe the present invention concretely, but the present invention is not limited to the following examples. In addition, the following "parts" and "%" are mass standards unless otherwise indicated.

Synthetic example 1

[0057] Into a reaction vessel equipped with a stirring device, a thermometer, and a condenser, put 360 g (0.45 mol) of polycarbonate derived from 1,5-pentanediol and 1,6-hexanediol as a compound having two or more alcoholic hydroxyl groups. Ester diol (manufactured by Asahi Kasei Chemical Co., Ltd., number average molecular weight: 800), 81.4 g (0.55 mol) of dimethylol butyric acid, and 11.8 g (0.16 mol) of n-butanol as a molecular weight modifier (reaction terminator). Next, 151.2 g (1.08 mol) of hexamethylene diisocyanate, which is a compound having an isocyanate group that is not directly bonded to an aromatic ring, is charged, heated to 60° C. while stirring, and stopped at the moment when the temperature in the reaction vessel starts to drop. Heating again, continuing stirring at 80°C, confirming the absorption spectrum of isocyanate group with infrared absorption spectrum (2280cm-1 ) disappears and the reaction is terminated. Next, carbitol acetate was added until the so...

Synthetic example 2

[0059] Into a reaction vessel equipped with a stirring device, a thermometer, and a condenser, 360 g (0.45 mol) of a compound derived from 1,5-pentanediol and 1,6-hexanediol, which are compounds having two or more alcoholic hydroxyl groups, were charged. Carbonate diol (manufactured by Asahi Kasei Chemical Co., Ltd., number average molecular weight: 800), 81.4 g (0.55 mol) of dimethylol butyric acid, and 11.8 g (0.16 mol) of n-butanol as a molecular weight modifier (reaction terminator). Next, 200.9 g (1.08 mol) of trimethylhexamethylene diisocyanate, which is a compound having an isocyanate group that is not directly connected to an aromatic ring, is put in, heated to 60° C. while stirring, stops, and the temperature in the reaction vessel starts Heat again when it is lowered, continue stirring at 80°C, and confirm the absorption spectrum of the isocyanate group with infrared absorption spectrum (2280cm -1 ) disappears and the reaction is terminated. Next, carbitol acetate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com