Resin composition, prepreg manufactured by using same, metal foil laminate and interlayer insulating film

A technology of resin composition and prepreg, applied in the direction of metal layered products, synthetic resin layered products, layered products, etc., can solve the problems of accelerating the ring-opening reaction of benzoxazine, narrowing the rheological window, and water absorption, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

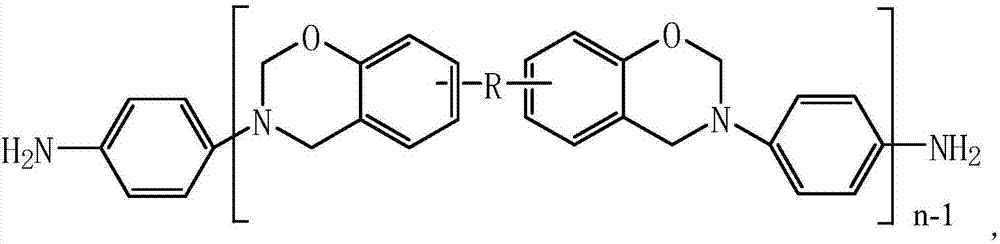

[0092] In a 500ml three-neck flask equipped with a stirrer, a reflux condenser and a thermometer, place it in an oil bath, add bisphenol A: 91.2g, p-phenylenediamine: 94.4g, formaldehyde: 48.0g; then add 80ml of ethanol and 20ml of toluene was used as a solvent, and the temperature was slowly raised to 75° C. and kept for 3 hours. During the process, the stirring state was kept continuously, and nitrogen was bubbled into the three-necked flask for protection. Above-mentioned reaction finishes, and after the product is cooled to room temperature, keep stirring and dropwise add methanol solution in the flask, to no longer having precipitate to separate out, stop stirring, leave standstill 24hr under room temperature, filter supernatant liquid, collect precipitate, will The precipitate was placed in a vacuum drying oven at 50°C and dried for 5 hours to obtain a diamine containing a benzoxazine structure, which was designated as N(BOZ)-1.

Synthetic example 2

[0094] In a 500ml three-neck flask equipped with a stirrer, a reflux condenser and a thermometer, place it in an oil bath, add bisphenol F: 79.2g, p-phenylenediamine: 94.4g, formaldehyde: 48.0g; then add 80ml of ethanol and 20ml of toluene was used as a solvent, and the temperature was slowly raised to 60° C. and kept for 5 hours. During the process, the stirring state was continuously maintained, and nitrogen was bubbled into the three-necked flask for protection. Above-mentioned reaction finishes, and after the product is cooled to room temperature, keep stirring and dropwise add methanol solution in the flask, to no longer having precipitate to separate out, stop stirring, leave standstill 24hr under room temperature, filter supernatant liquid, collect precipitate, will The precipitate was placed in a vacuum drying oven at 50°C and dried for 5 hours to obtain a diamine containing a benzoxazine structure, which was designated as N(BOZ)-2.

[0095] Modified resin example one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com