Light curing 3D printing equipment and image exposure system

A 3D printing and exposure system technology, applied in the field of image exposure systems, can solve the problems of limited resolution, restrict development, limit applications, etc., and achieve the effect of increasing resolution and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

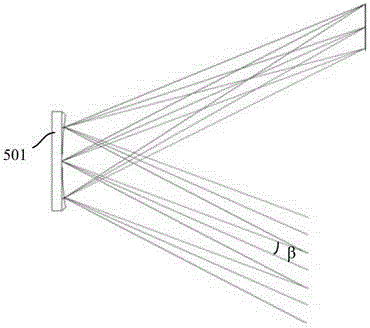

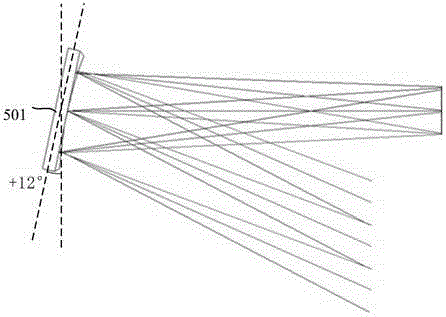

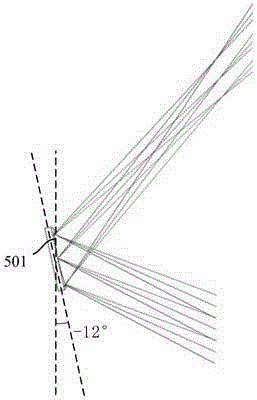

[0042] The embodiment of the present invention describes a 3D printing device and its image exposure system, and the image exposure system uses a digital micromirror element as an area array image source.

[0043] figure 2 An image exposure system of a 3D printing device according to an embodiment of the present invention is shown. refer to figure 2 As shown, the image exposure system 200 of the present embodiment includes a light source 201, a bandpass color filter 202, an integrating rod 203, a relay optical element 204, a reflector 205, a digital micromirror element 206, and a TIR (Total Internal Reflection, all internal reflection) prism 207, projection lens 208 and controller (not shown). For the sake of clarity, components not relevant to the present invention are not shown.

[0044] The light source 201 is used to generate light beams to be irradiated onto the DMD 206 . The wavelength of the light emitted by the light source 201 depends on the cured photosensitive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com