Gallium nitride-based light emitting diode epitaxial wafer and manufacturing method thereof

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of warping of epitaxial wafers, affecting the uniformity of emission wavelength of multi-quantum well layers, etc., to achieve smooth surface and improve optoelectronic performance , the effect of surface energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

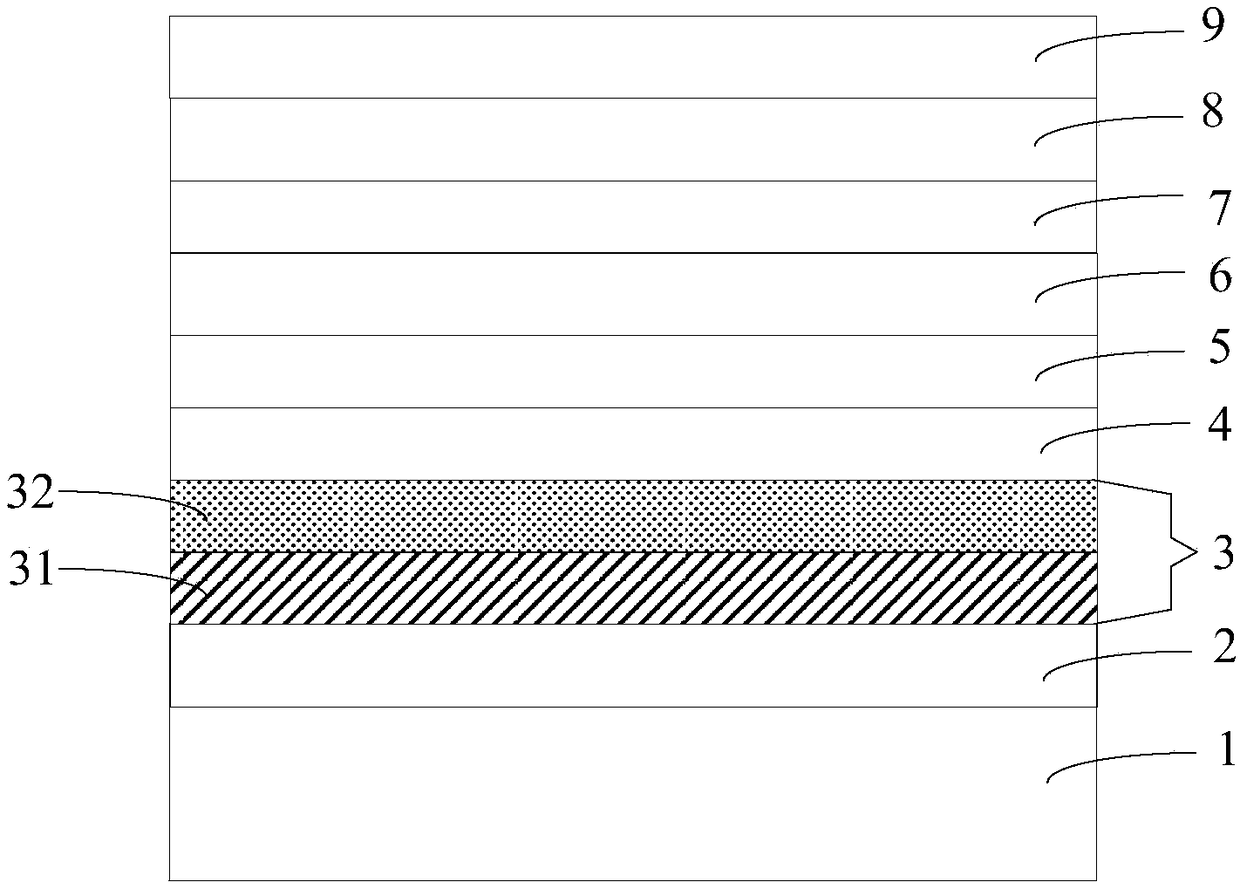

[0034] An embodiment of the present invention provides a GaN-based light-emitting diode epitaxial wafer, figure 1 It is a schematic structural diagram of a gallium nitride-based light-emitting diode epitaxial wafer provided by an embodiment of the present invention, as shown in figure 1 As shown, the gallium nitride-based light-emitting diode includes a sapphire substrate 1, and an AlN buffer layer 2, a 3D nucleation layer 3, an undoped GaN layer 4, an N-type layer 5, and Multiple quantum well layer 6 , electron blocking layer 7 , high temperature P-type layer 8 and P-type contact layer 9 .

[0035] Wherein, the 3D nucleation layer 3 includes a first sublayer 31 and a second sublayer 32, the first sublayer 31 is a GaN layer grown at 800-1100°C, and the second sublayer 32 is grown at 1000-1200°C The GaN layer grown under it.

[0036] In the embodiment of the present invention, the 3D nucleation layer is divided into a first sublayer and a second sublayer. The first sublayer i...

Embodiment 2

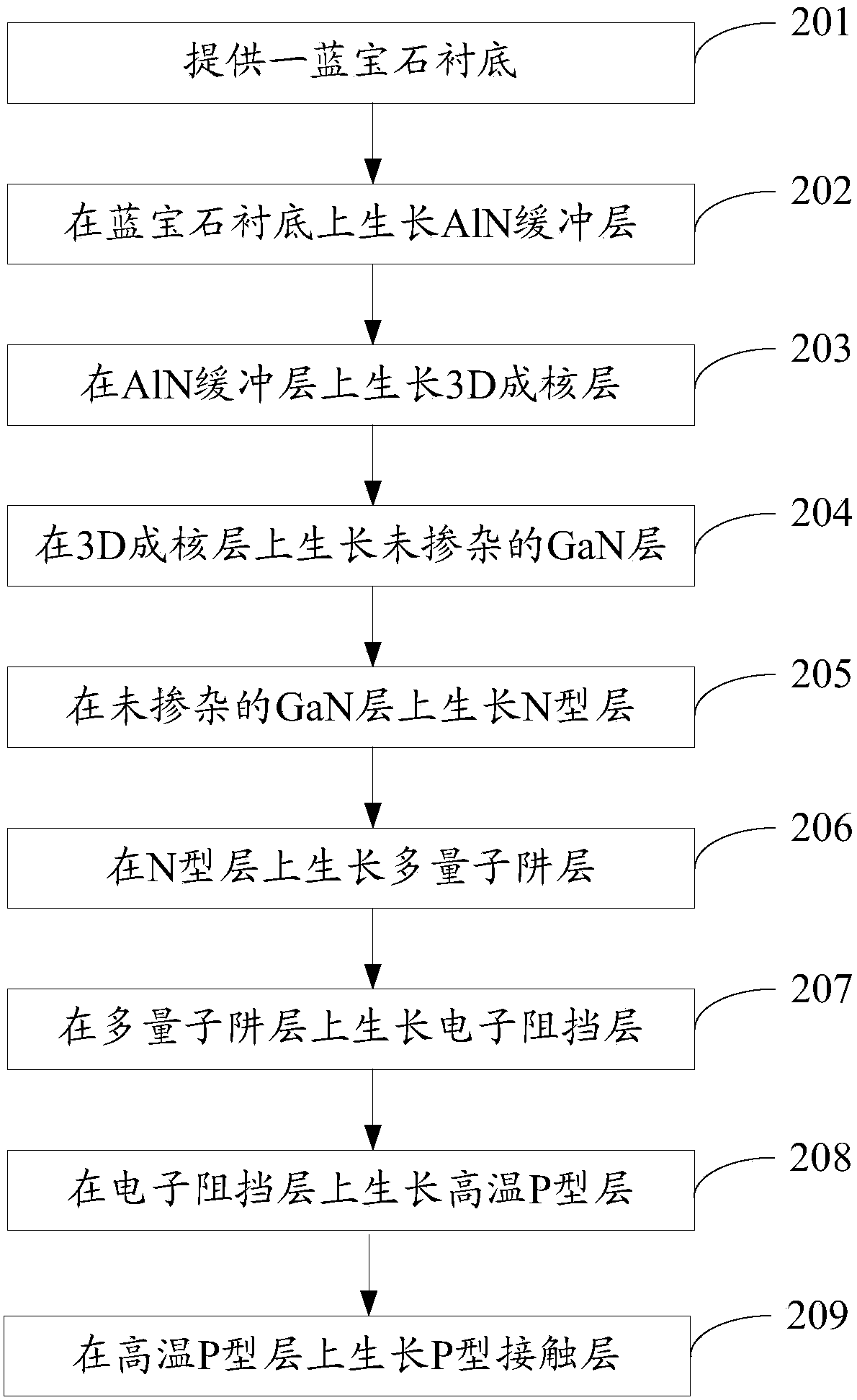

[0049] An embodiment of the present invention provides a method for manufacturing a gallium nitride-based light-emitting diode epitaxial wafer, which is suitable for the gallium nitride-based light-emitting diode epitaxial wafer provided in Embodiment 1. figure 2 It is a flow chart of a method for preparing a gallium nitride-based light-emitting diode epitaxial wafer provided by an embodiment of the present invention, as shown in figure 2 As shown, the manufacturing method includes:

[0050] Step 201, providing a sapphire substrate.

[0051] Specifically, the sapphire substrate is sapphire with a thickness of 630-650um.

[0052] In this embodiment, Veeco K465i or C4MOCVD (Metal Organic Chemical VaporDeposition, metal organic compound chemical vapor deposition) equipment is used to realize the LED growth method. Using high-purity H 2 (hydrogen) or high-purity N 2 (nitrogen) or high purity H 2 and high purity N 2 The mixed gas as the carrier gas, high-purity NH 3 As N s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com