Anti-warp glass fiber reinforced polycarbonate composition with high rigidity and toughness and good appearance

A technology of high rigidity and toughness, polycarbonate, applied in the field of glass fiber reinforced polycarbonate composition with high rigidity, good appearance and anti-warpage, which can solve unfavorable production and cost control, need to improve warpage resistance, and demanding raw materials and other problems, to achieve the effect of improving warpage and surface appearance, improving injection fluidity, excellent rigidity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

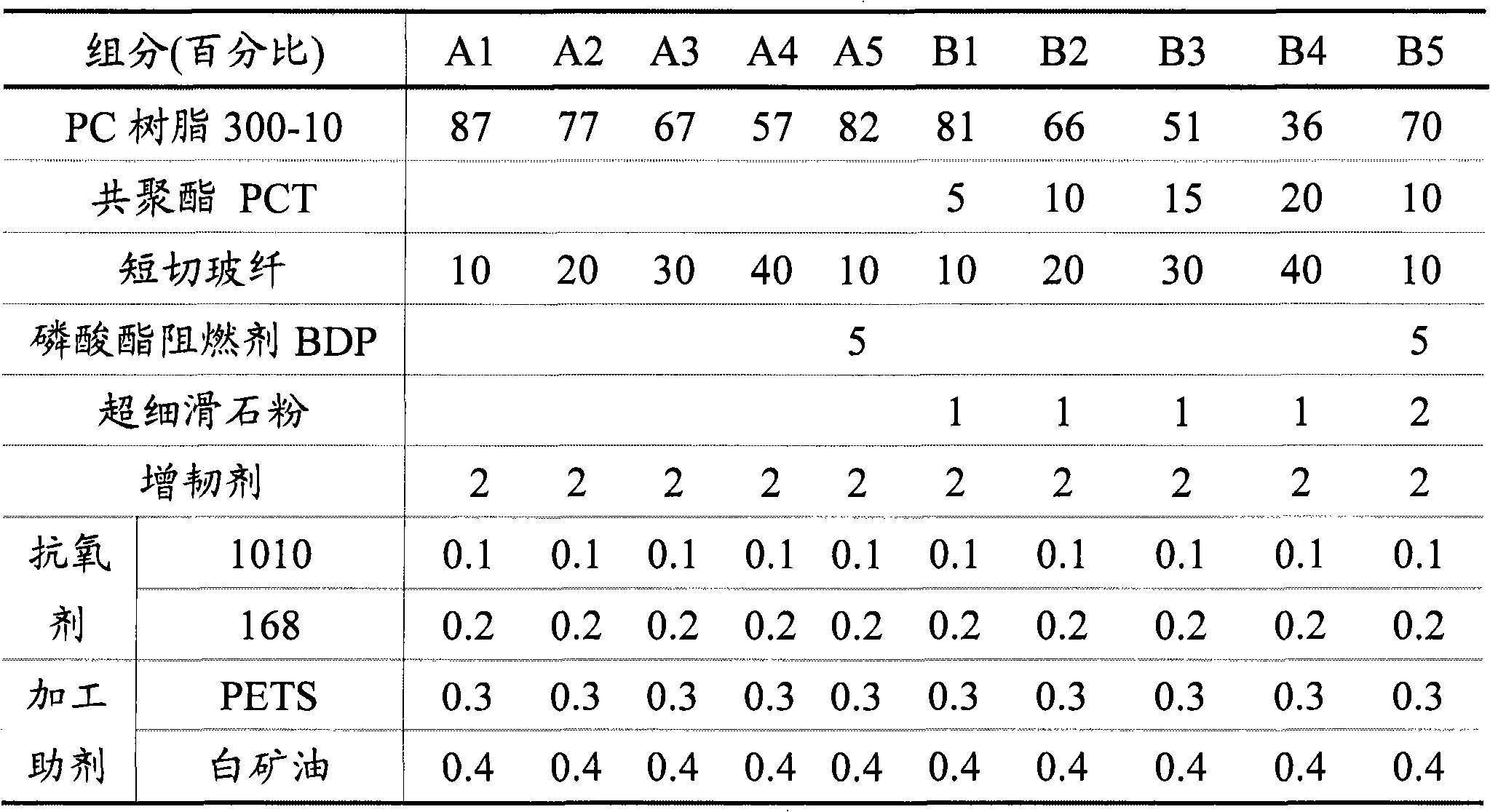

[0018] In this part, A1-A5 are used to represent Comparative Examples 1-5, and B1-B5 are used to represent Examples 1-5.

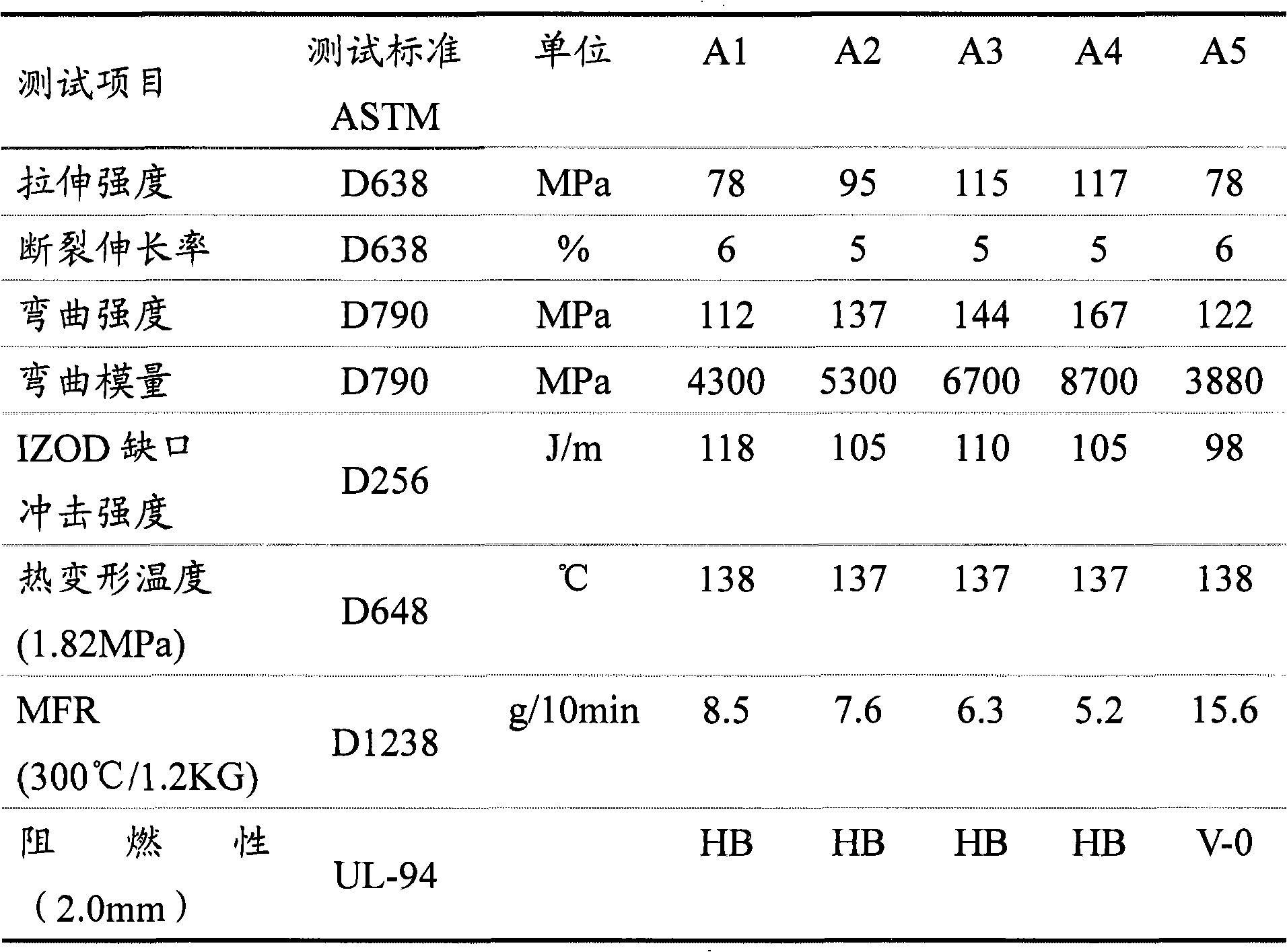

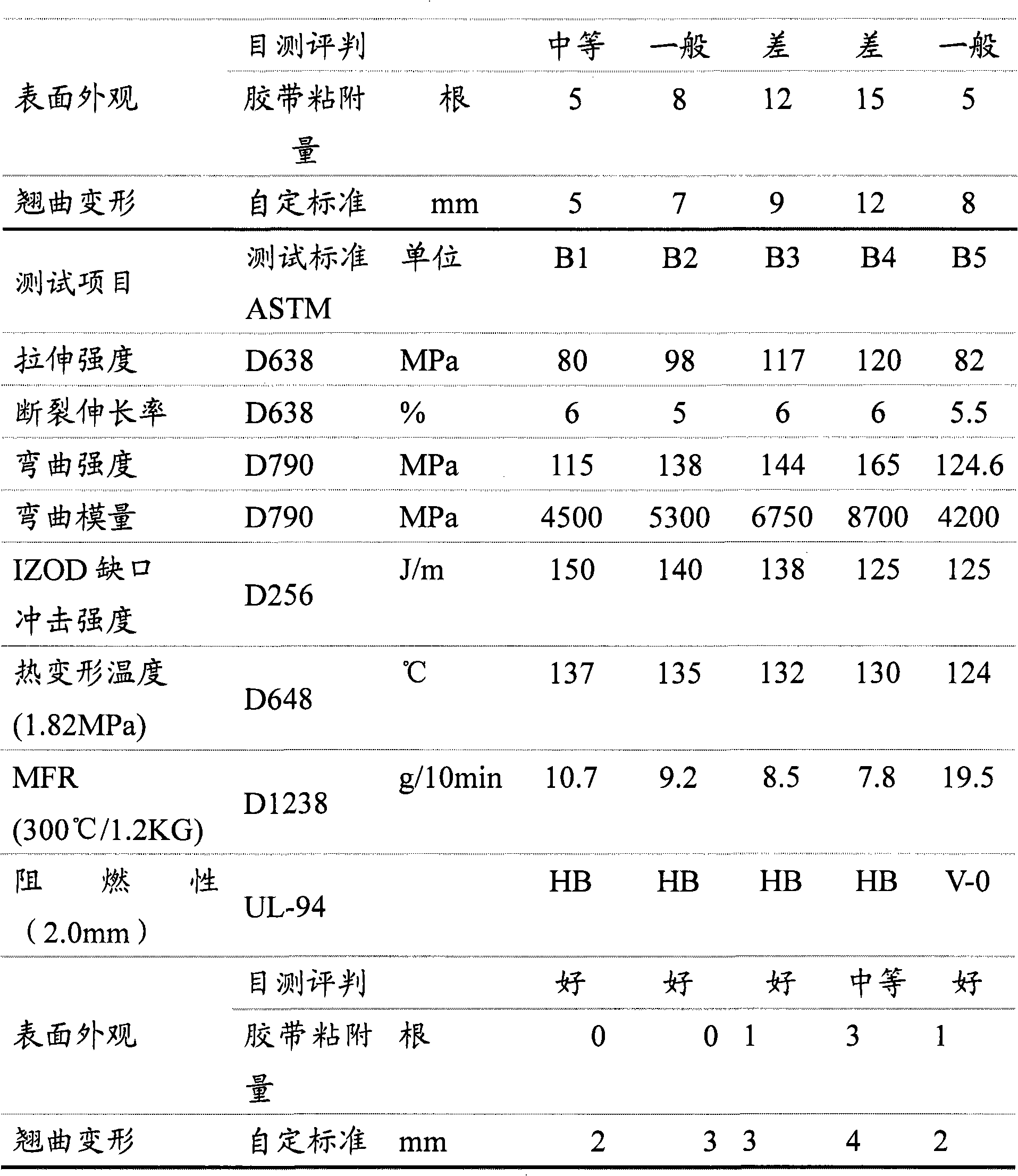

[0019] According to Table 1, mix the components except the glass fiber in a high-speed mixer for 2-3 minutes, and then extrude and granulate at 230-260°C. During this process, long glass fibers or short The cut glass fiber is fed to the extruder in proportion. The granulated pellets were dried and then injection molded into standard specimens at a temperature of 280°C. The mechanical properties were tested according to ASTM standards, as shown in Table 2.

[0020] The degree of warpage deformation and appearance are judged by the company's internal self-defined test method:

[0021] (1) Determination of warpage deformation: Under the same injection molding process conditions, different materials are injected into parts with a length of 50cm x width 5cm x thickness 2.0cm, and after being placed at room temperature for 24 hours, the distance from the horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com