Low warping PP (propene polymer) material for 3D (three-dimensional) printing and preparation method thereof

A 3D printing, low-warping technology, applied in the field of 3D printing materials, can solve the problems of inability to print, poor printing stability, and easy warping of printing, and achieve the effects of reducing shrinkage, eliminating stress, and preventing warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

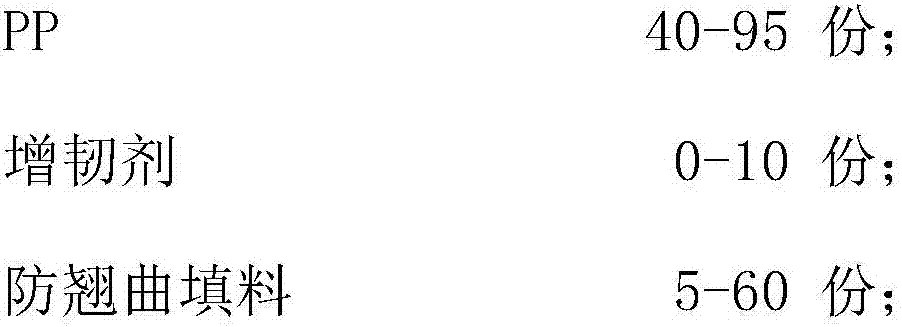

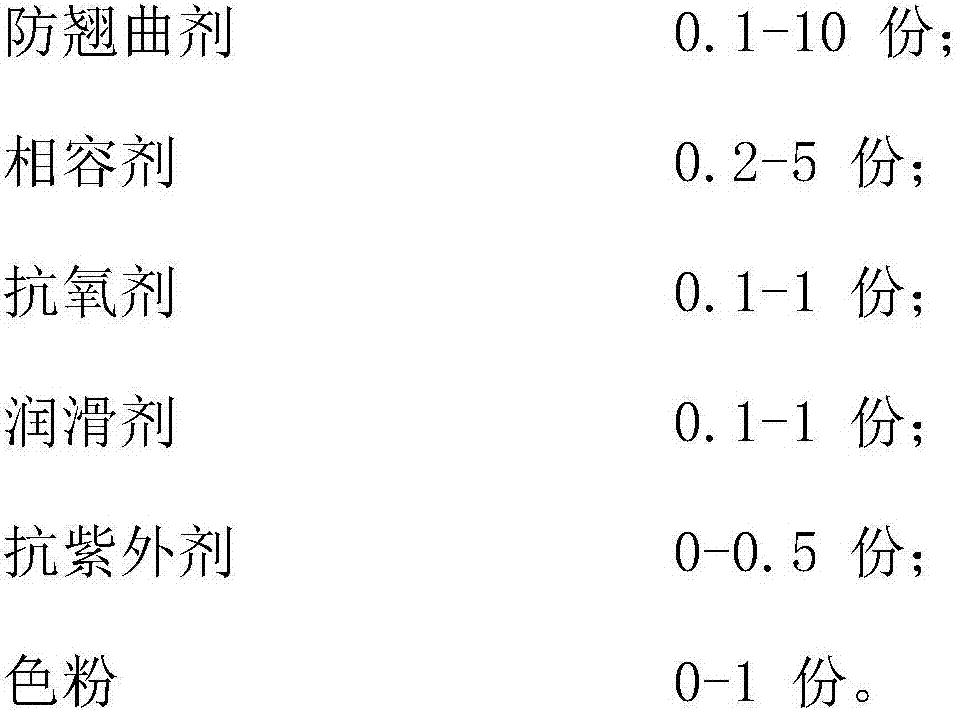

Method used

Image

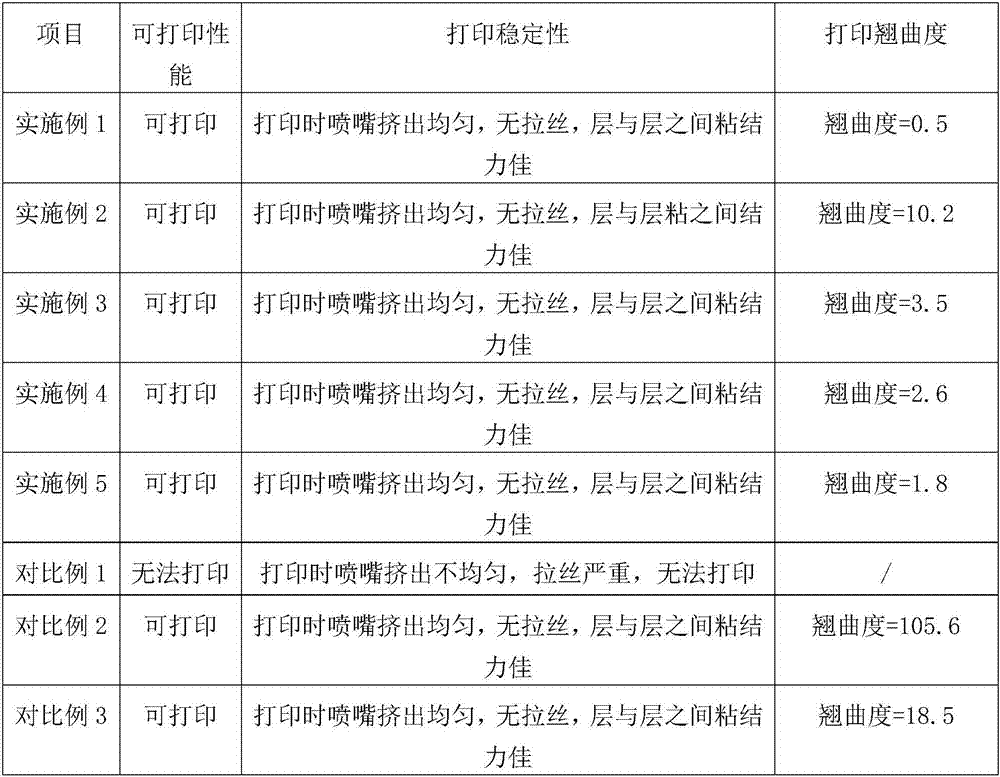

Examples

Embodiment 1

[0035] Step 1: Weigh the raw materials of each component according to the component distribution ratio of the low-warpage PP material for 3D printing and its preparation method, and mix 40Kg of homopolymerized PP, 60Kg of barium sulfate (5μm, sphericity ≥ 60%), 10Kg of POE, and Warpage nucleating agent HPN-68L 0.1Kg, PP-g-MAH 5Kg, 1010 0.5Kg, 168 0.5Kg, montan wax 1Kg mechanically mix evenly;

[0036] Step 2: Extrude the mixed material through a twin-screw extruder at a processing temperature of 250°C, cool at normal temperature, air-dry, and pelletize to make modified PP pellets;

[0037]Step 3: Extrude the modified PP pellets through a 3D printing material extruder at a processing temperature of 250°C, cooling at a high temperature at 20°C, cooling at a medium temperature at a constant temperature at 20°C, cooling at room temperature, air-drying, drawing, and coiling. A low warpage PP material for 3D printing and a preparation method thereof.

Embodiment 2

[0039] Step 1: Weigh the raw materials of each component according to the component distribution ratio of the low-warpage PP material for 3D printing and its preparation method, mix 95Kg of random copolymerized PP, 5Kg of ceramic microbeads (15μm, sphericity ≥ 80%), and 10Kg of HDPE , KH560 0.5Kg, 10100.05Kg, DLTP 0.05Kg, erucamide 0.1Kg, anti-ultraviolet agent 944 0.5Kg, titanium dioxide 1Kg and mechanically mix evenly;

[0040] Step 2: Extrude the mixed material through a twin-screw extruder at a processing temperature of 190°C, cool at normal temperature, air-dry, and pelletize to make modified PP pellets;

[0041] Step 3: Extrude the modified PP pellets through a 3D printing material extruder at a processing temperature of 180°C, then cool at a high temperature at a high temperature of 70°C, at a medium temperature at a constant temperature of 50°C, at room temperature, air-dry, draw strips, and coil to make A low warpage PP material for 3D printing and a preparation metho...

Embodiment 3

[0043] Step 1: Weigh the raw materials of each component according to the component distribution ratio of the low-warpage PP material for 3D printing and its preparation method, and mix 70Kg of block copolymerized PP, 30Kg of solid glass microspheres (10μm, sphericity ≥ 90%), and Warpage nucleating agent Irgastab NA 2870.6Kg, KH550 0.5Kg, 1010 0.1Kg, 168 0.2Kg, EBS 0.1Kg, calcium stearate 0.1Kg, anti-ultraviolet agent V7030.1Kg mechanically mixed uniformly;

[0044] Step 2: Extrude the mixed material through a twin-screw extruder at a processing temperature of 230°C, cool at normal temperature, air-dry, and pelletize to make modified PP pellets;

[0045] Step 3: Extrude the modified PP pellets through a 3D printing material extruder at a processing temperature of 200°C, cooling at a high temperature at 25°C, cooling at a medium temperature at a constant temperature at 20°C, cooling at room temperature, air drying, stripping, and coiling. A low warpage PP material for 3D printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com