Automatic motor stator end copper wire riveting and welding line

A motor stator and automatic line technology, which is applied in the manufacture of stator/rotor bodies, electric components, and motor generators. It can solve the problems of large labor costs, irregularities, and low production capacity, so as to reduce labor costs and increase the pass rate. , the effect of high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

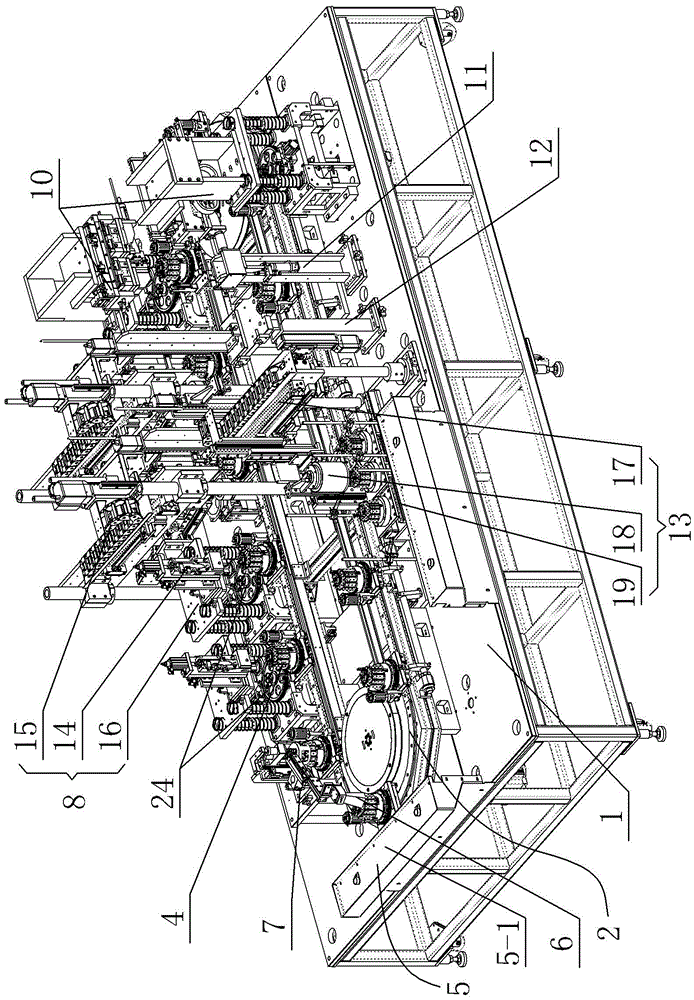

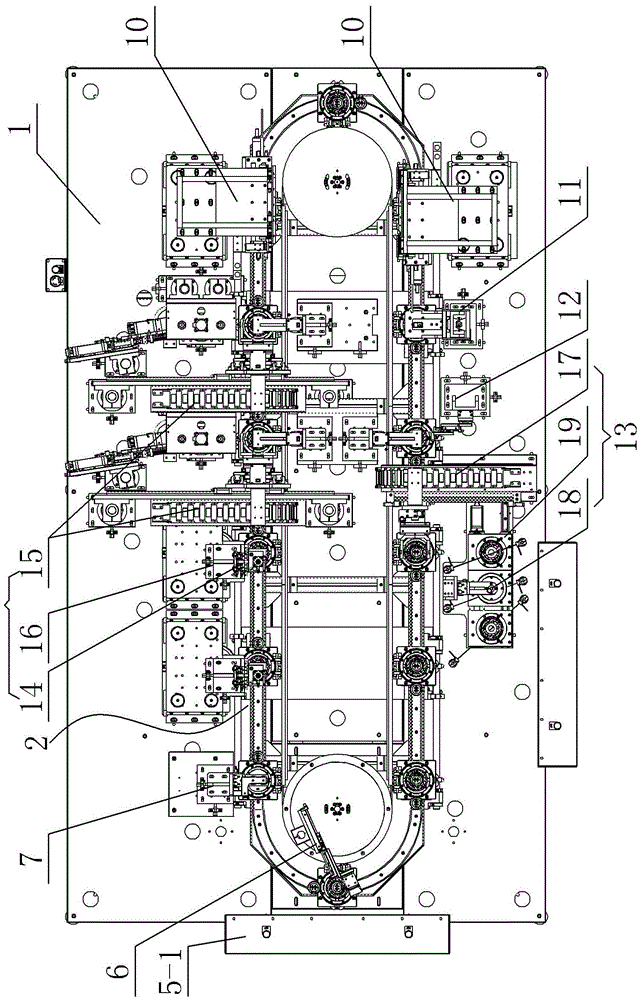

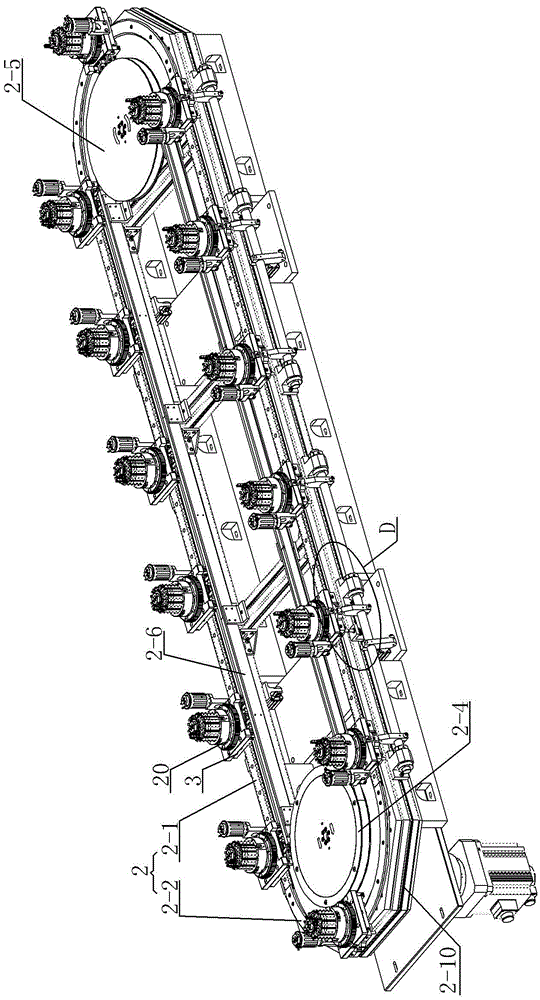

[0057] Motor stator end copper wire riveting welding automatic line, see Figure 1-18: It includes a frame 1, and the frame 1 is provided with a runway-shaped track structure 2, and the runway-shaped track structure 2 includes two sections of parallel linear tracks 2-1, two sections of arc-shaped tracks 2-2, and two sections of arc-shaped tracks 2 The head and the tail of -2 are respectively connected with the corresponding sections of the two ends of the linear track 2-1 on the corresponding side to form a track structure 2, and the corresponding center positions of the arc track 2-2 at both ends are respectively arranged with a guide wheel structure , one of which is the driving guide wheel 2-4, the other is the driven guide wheel 2-5, the driving guide wheel 2-4 and the driven guide wheel 2-5 are connected by a synchronous belt 2-6, and the synchronous belt 2- The outer side of 6 is uniformly equipped with several jig supporting seats 3, each set of jigs is supported on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com