Optical imaging lens

An optical imaging lens and imaging technology, applied in optics, optical components, lenses, etc., can solve the problems of shrinking the size of the imaging lens, too long distance, and reduced imaging quality, so as to improve the assembly yield, good optical performance, and expand the field of view. The effect of field angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0141] Compared with the first embodiment, the TTL of this embodiment becomes smaller, and the HFOV becomes larger. Furthermore, the second embodiment is easier to manufacture, has better image quality and higher yield.

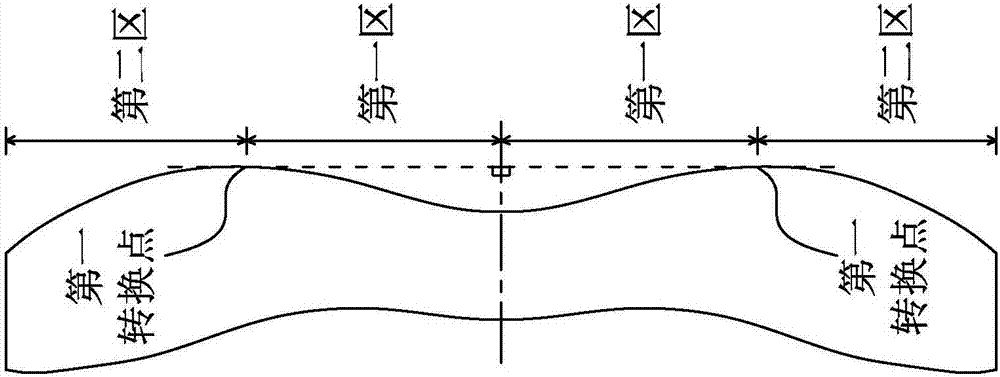

[0142] Please also refer to Figure 14 to Figure 17 , wherein FIG. 14 shows a schematic cross-sectional structure diagram of a six-element lens of an optical imaging lens according to a third embodiment of the present invention, and FIG. 15 shows longitudinal spherical aberration and various items of an optical imaging lens according to a third embodiment of the present invention. Schematic diagram of aberration diagram, Figure 16 Show detailed optical data of the optical imaging lens according to the third embodiment of the present invention, Figure 17 The aspheric data of each lens of the optical imaging lens according to the third embodiment of the present invention is shown. In this embodiment, similar symbols are used to indicate similar elements as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com