Optical composite film and preparation method thereof

An optical composite film and optical film technology, applied in optics, optical components, nonlinear optics, etc., can solve the problem that composite films cannot take into account the brightness gain, covering and de-interference, etc., to achieve excellent de-interference performance and improve brightness. Amplification effect, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

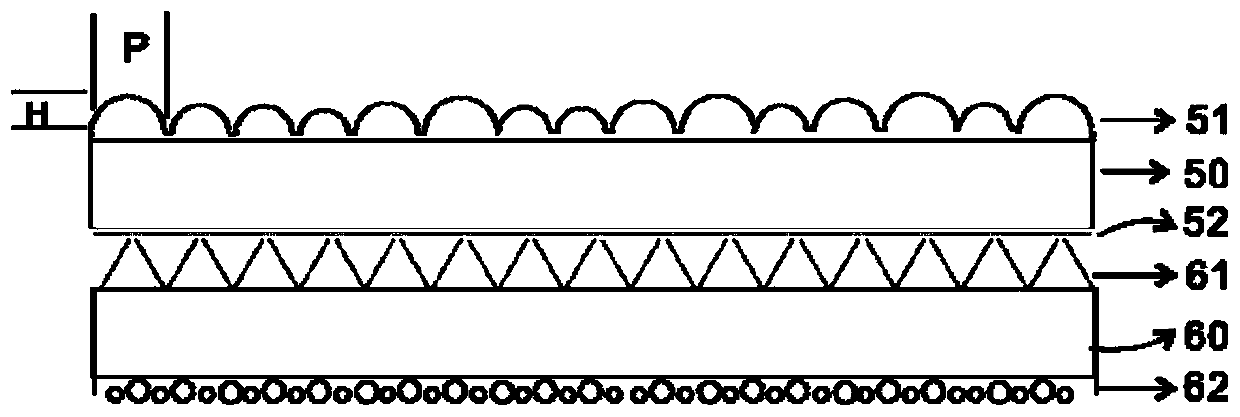

[0089] Such as image 3 As shown, the present invention provides an optical composite film, the optical composite film comprising: a first layer of optical film and a second layer of optical film; the first layer of optical film is placed above the second layer of optical film, the two through The bonding layer 52 is bonded together; the first layer of optical film includes the microlens structure layer 51, and the first layer of substrate layer 50; the second layer of optical film includes the prism layer 61 in sequence, and the second layer of base layer Material layer 60, and back coating 62.

Embodiment 2-10

[0091] For the optical composite film provided in Example 1, the technical parameters are shown in Table 1.

[0092] The technical parameters of Embodiment 1-10 are shown in Table 1-1 and Table 1-2 below.

[0093] The technical parameters of the first layer of optical film of the optical composite film that table 1-1 embodiment 1-10 provides

[0094]

[0095] Note: The refractive index of the prism resin generally refers to the refractive index of the glue before curing, and the index that can be detected is also the refractive index before curing, so it can also be called the refractive index of the resin finger liquid.

[0096] The technical parameters of the second optical film and the bonding layer of the optical composite film provided in Table 1-2 Examples 1-10

[0097]

[0098]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com