Sealed cooling tower

A cooling tower, closed technology, applied in the field of sealed cooling towers, can solve the problems of poor light and thermal stability of polyvinyl chloride, damage to equipment structure and performance, uneven quality, etc., to achieve safe and reliable operation and improve cooling efficiency , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

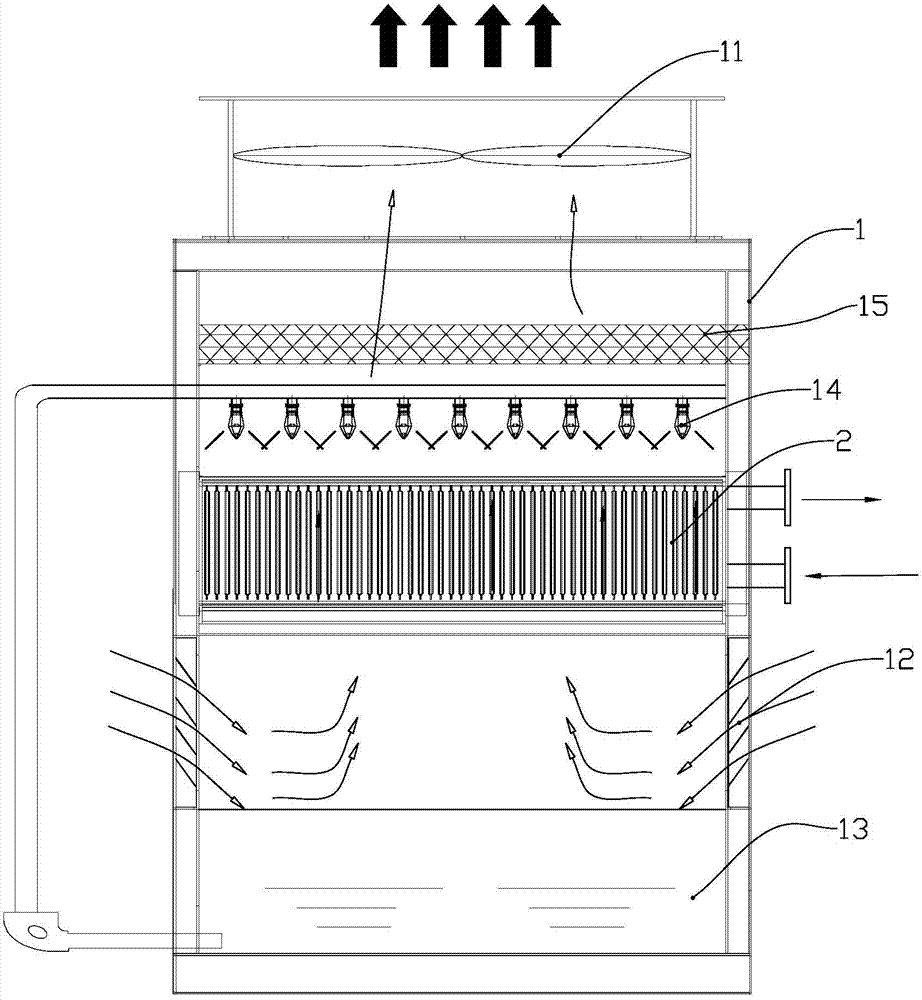

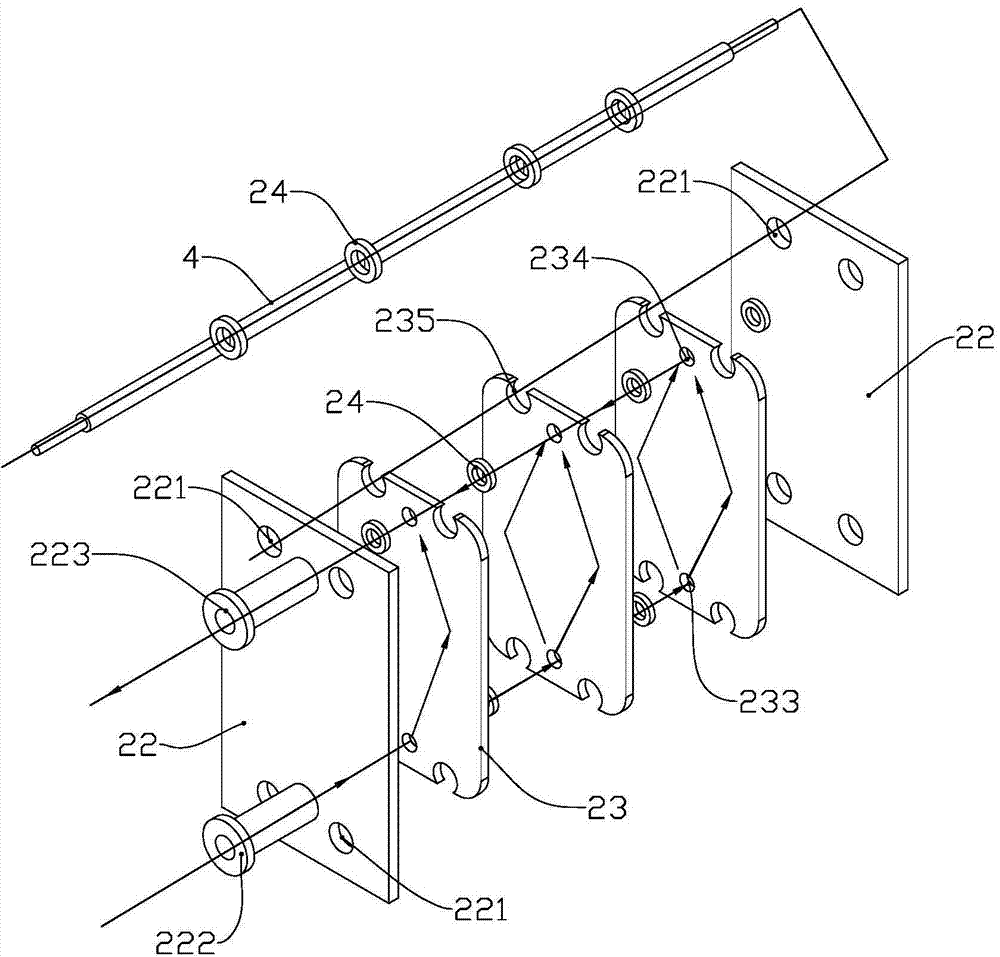

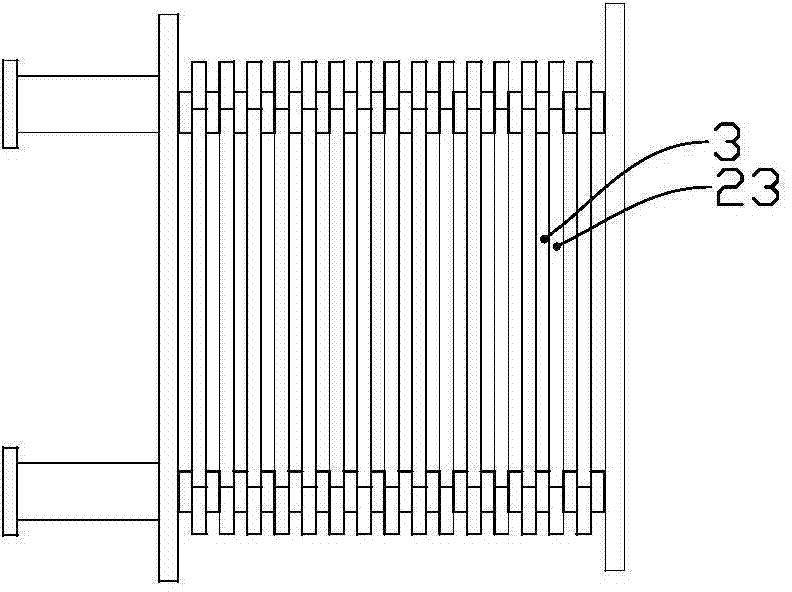

[0036] Such as Figure 1 to Figure 7 as shown,

[0037] A key point and protection point of the present invention is a plate-type closed cooling tower with an outer shell of galvanized steel plate, in which the outer guard plate, top plate, bottom plate and air outlet of the cooling tower are made of galvanized steel plate with high corrosion resistance , The corrosion resistance of galvanized steel sheet is 6-8 times that of ordinary galvanized steel sheet, and it can still maintain its original appearance in harsh environments. At the same time, it has a unique self-healing and anti-corrosion performance of the cut surface coating, stable processing performance, excellent wear resistance and scratch resistance, beautiful appearance and long service life. This type of cooling tower has the characteristics of beautiful appearance, flexible combination, high efficiency and low consumption, environmental protection and energy saving, easy maintenance, firm structure and long se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com