Bicycle freewheel

A bicycle and flywheel technology, applied in the field of flywheels, can solve the problems of complicated assembly work and complicated structure of the one-way clutch, and achieve the effect of small clearance angle and simple internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

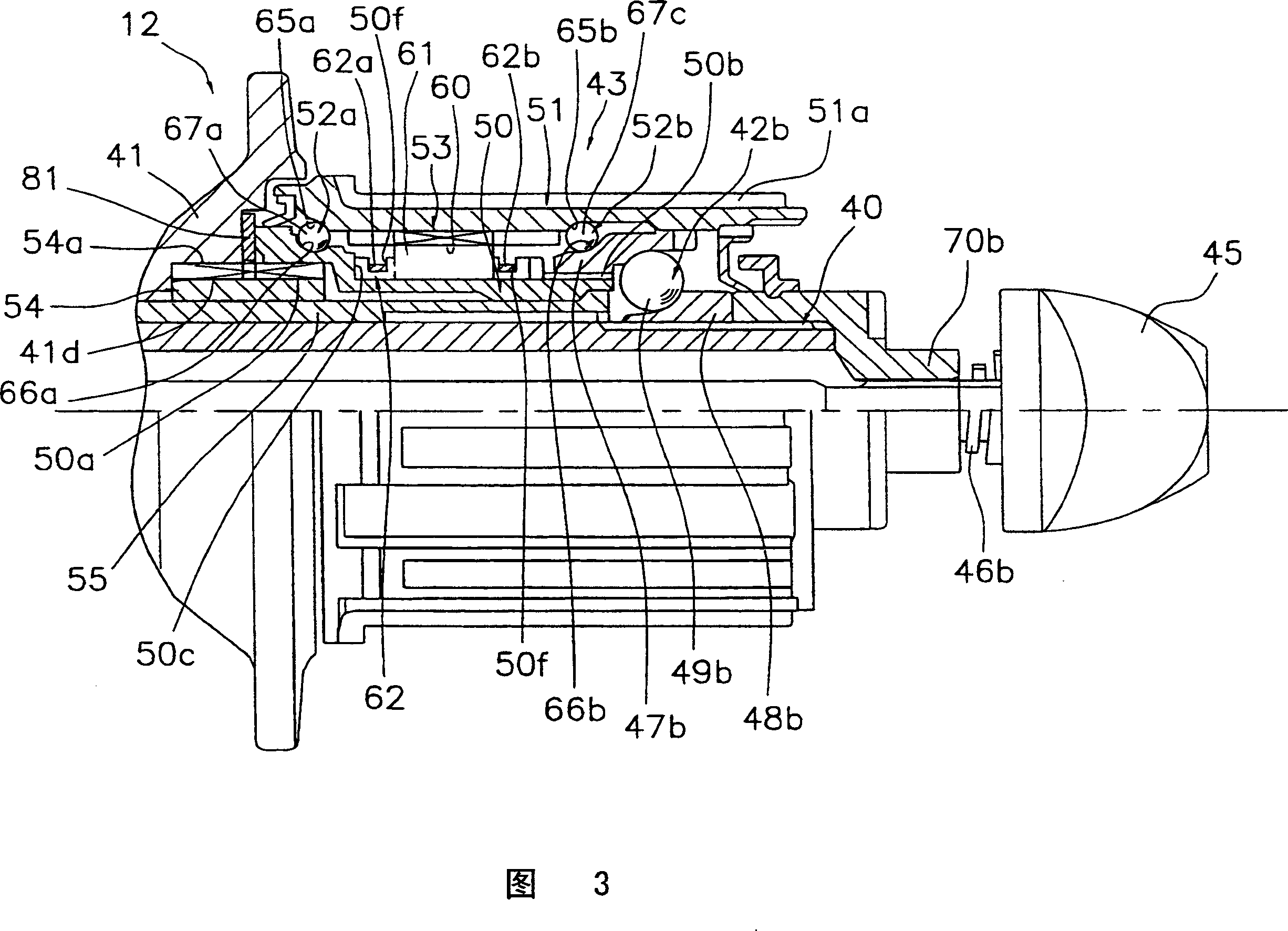

[0061] (a) In the aforementioned embodiment, in order to maintain the necessary rigidity and reduce the clearance angle, the two clutch pawls 61 are simultaneously engaged with the ratchet teeth 60. However, in order to reduce the clearance angle, only one clutch pawl may be used. 61 meshes with ratchet teeth 60 .

[0062] In Fig. 7, the central angle β2 of the two adjacent clutch claws 61 rotating clockwise among the first to fourth clutch claws 61a to 61d is 75 degrees, and the first clutch claw 61a and the adjacent second clutch claw 61a rotating counterclockwise The central angle γ2 between the four clutch claws 61d (that is, the central angle γ2 between the first clutch claw 61a and the fourth clutch claw 61d without the second and third clutch claws 61b, 61c in between) is 135 degrees.

[0063] Of the first to fourth clutch claws 61 a to 61 d thus arranged, only one of the first to fourth clutch claws 61 a to 61 d meshes with the ratchet teeth 60 . That is, since the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com