Reaction system for bubbling tower type Fischer-Tropsch synthesis slurry bed

A technology of reaction system and bubble tower type, which is applied in the field of bubble tower slurry bed reaction system and equipment, can solve the problems of external power operation cost increase, pulverization, performance degradation, etc., and achieve the realization of equipment composition and operation system, suppression of performance degradation, and reduction in operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

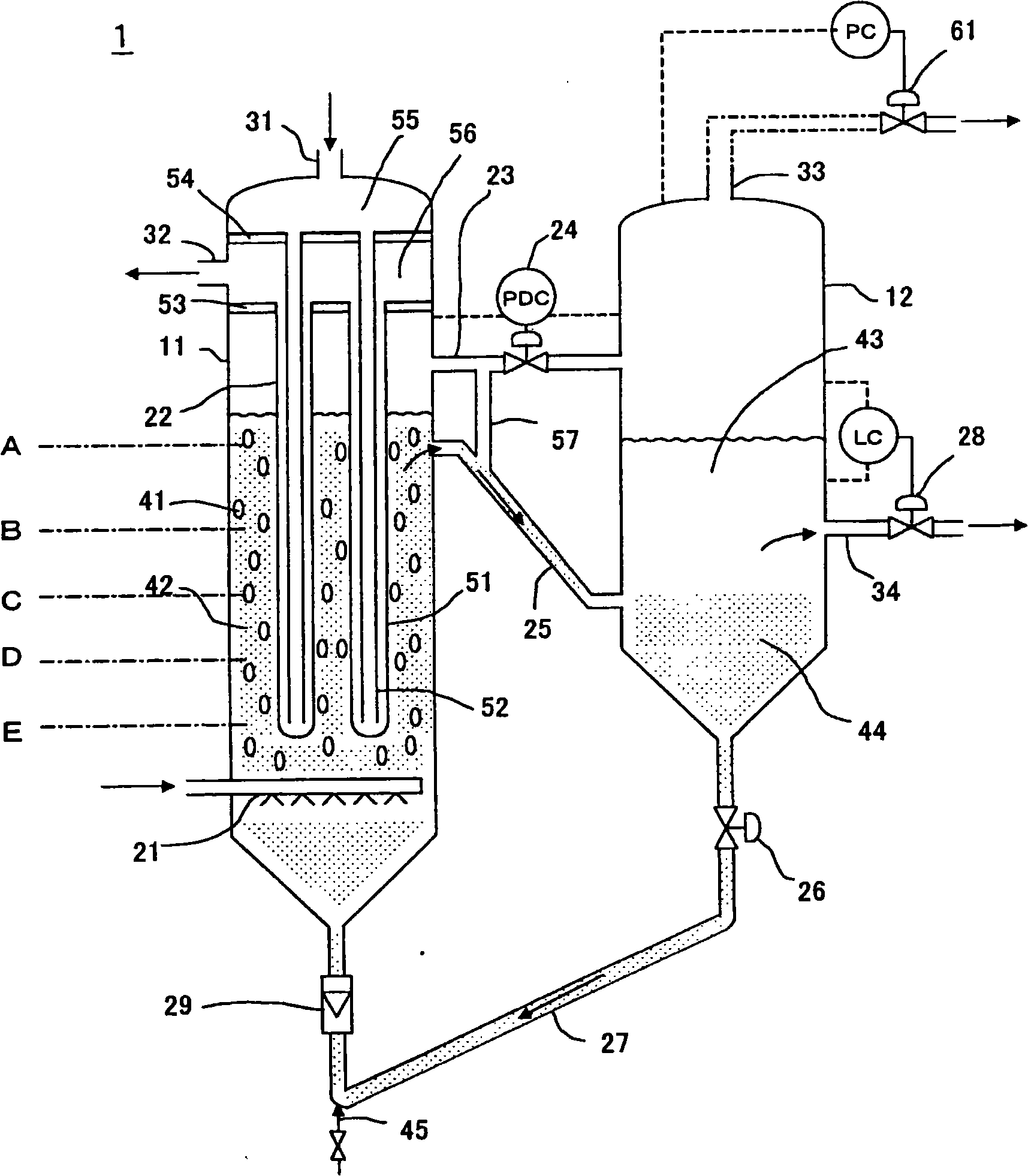

[0103] As a reaction device, use figure 1 device shown.

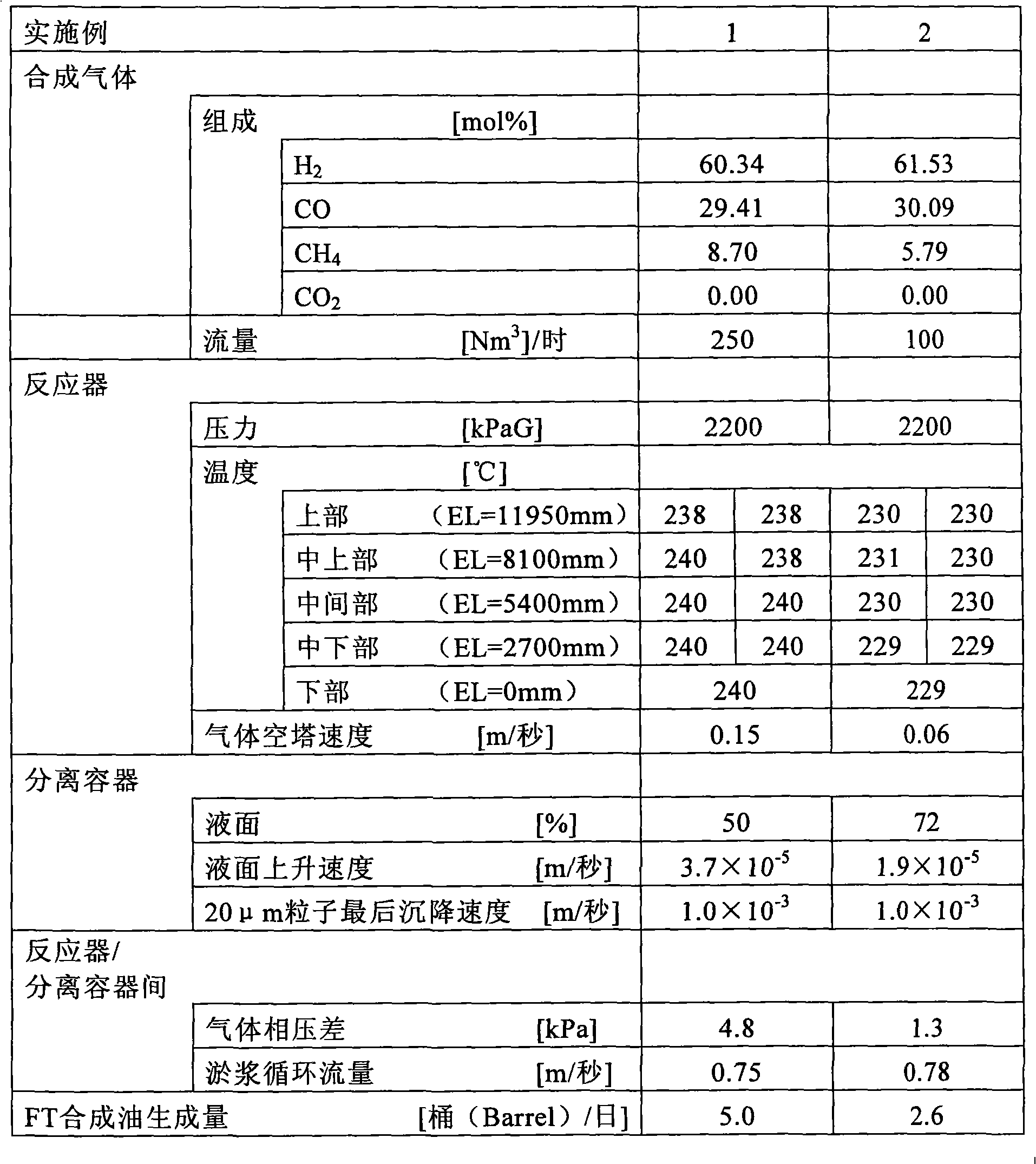

[0104] Synthetic gas supply is 250Nm 3 / hour (100% load), the reaction pressure was controlled at 2200 kPaG, the reaction temperature was controlled at 240° C. (±2° C.), and liquid hydrocarbons produced by the FT synthesis reaction were produced. The results are shown in Table 1. The reaction temperature in the reactor is adjusted to the above temperature range, and the following adjustments are made at the same time: boiler water is introduced into the inner tubes of multiple bayonet-type cooling tubes, and steam at a temperature of 231 °C and a pressure of 2735 kPaG is obtained from the outlet of the outer tubes of the cooling tubes. In addition, under the present operating conditions, the conversion rate of CO in the FT synthesis reaction was 62%.

[0105] Under the condition that the gas superficial velocity is 0.15m / s, the temperature distribution inside the reactor shows a uniform temperature distribution with ...

Embodiment 2

[0107] Using the same reaction device as in Example 1, the synthesis gas supply rate is 100Nm 3 / hour (40% load), the reaction pressure is controlled to 2200 kPaG, and the reaction temperature is controlled to 230° C. to produce liquid hydrocarbons produced by the FT synthesis reaction. The results are shown in Table 1. The reaction temperature in the reactor was adjusted to the above temperature range, and the following adjustments were made at the same time: boiler water was introduced into the inner tubes of multiple bayonet-type cooling tubes, and steam at a temperature of 226°C and a pressure of 2450kPaG was obtained from the outlets of the outer tubes of the cooling tubes. In addition, under the present operating conditions, the conversion rate of CO in the FT synthesis reaction was 89%.

[0108] Under the condition that the gas superficial velocity is 0.06m / s, the temperature distribution inside the reactor shows a uniform temperature distribution below 1°C in the vert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com