Solenoid-operated pilot type spool valve

A pilot type, pilot valve technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of complicated design and processing, complex internal structure of the valve body, etc., to achieve simple internal structure, easy design and processing, and easy distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

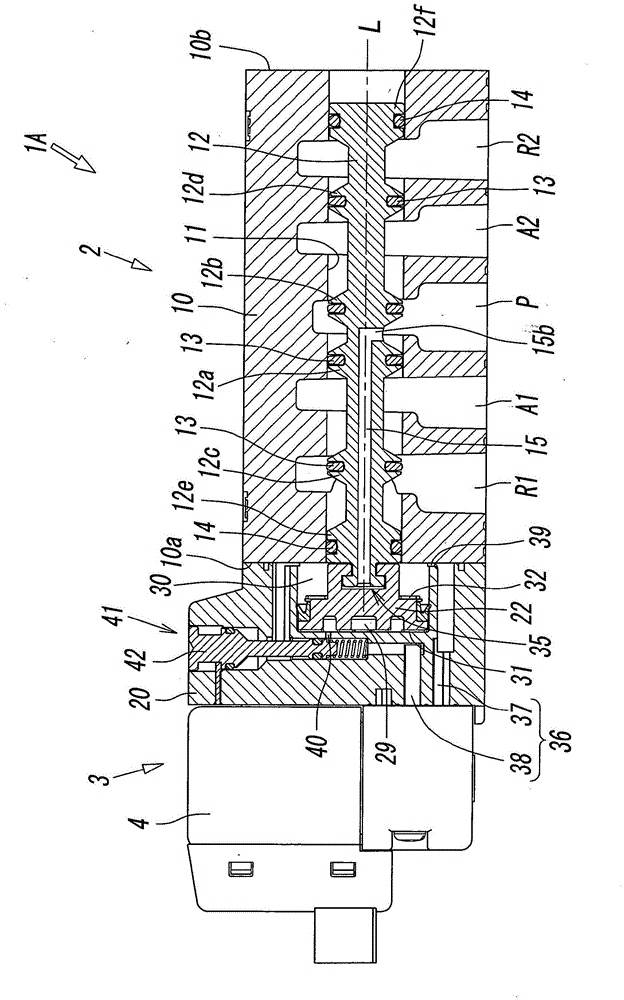

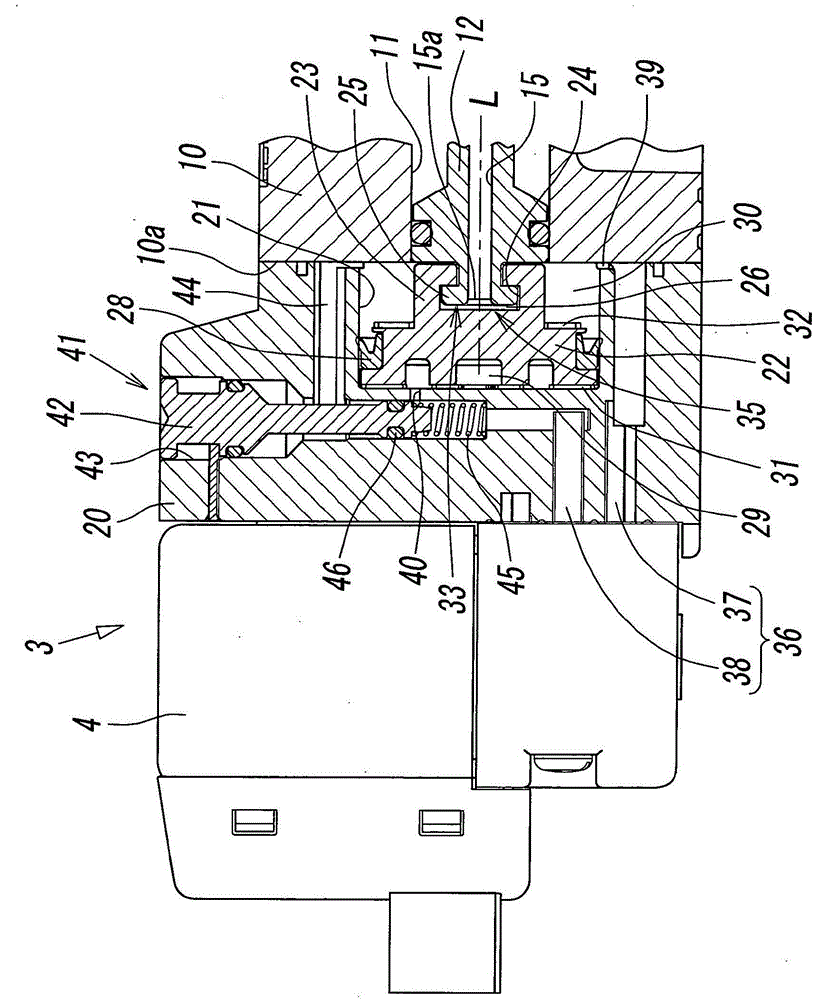

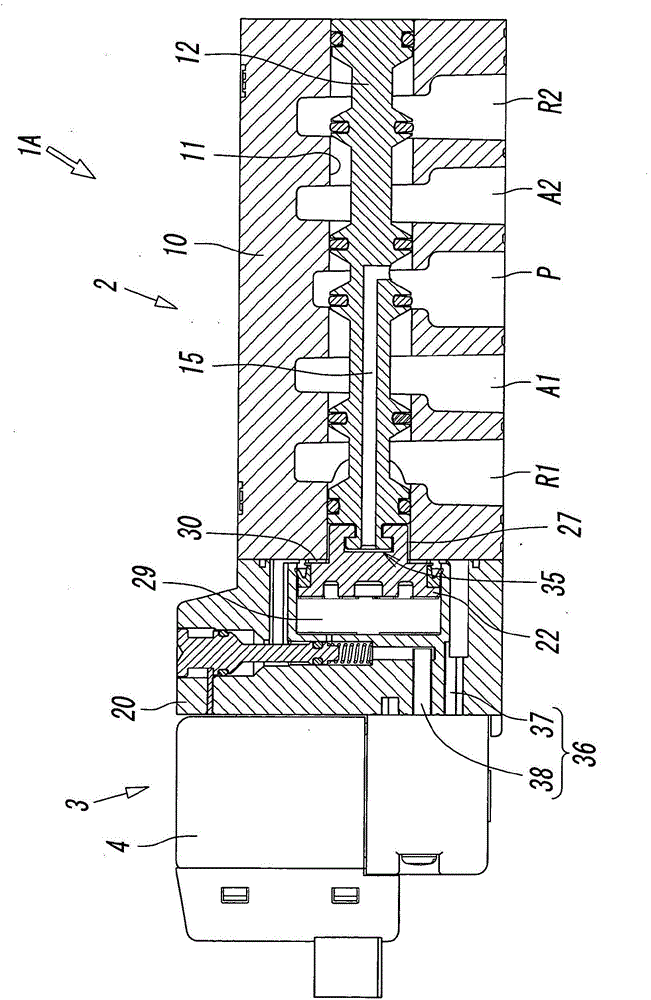

[0028] Figure 1-Figure 3 It is a figure which shows 1st Embodiment of the electromagnetic pilot type spool valve of this invention. The spool valve 1A according to the first embodiment is a single-pilot type spool valve having one pilot valve 4 , and includes a main valve portion 2 having a valve structure as a five-port valve, and one end side of the main valve portion 2 provided on the main valve portion 2 . of the pilot valve section 3.

[0029] Five ports P, A1, A2, R1, and R2 for input, output, and exhaust are formed in the valve body 10 of the main valve portion 2 described above. The arrangement of the five ports is such that the first and second output ports A1 and A2 are located on both sides of the central input port P, and the first and second exhaust ports R1 and R2 It is located on both outer sides of the first and second output ports A1 and A2. In addition, in the inside of the valve body 10, a circular valve hole 11 communicating with the five ports P, A1, A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com