Heating, sterilizing and drying appliance using superheated steam generator

A technology for superheated steam and heating appliances, which is applied in the directions of steam generation, heating, and sterilization. The effect of cost minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Best Mode for Carrying Out the Invention

[0019] Preferred embodiments of the present invention will now be discussed in detail with reference to the accompanying drawings.

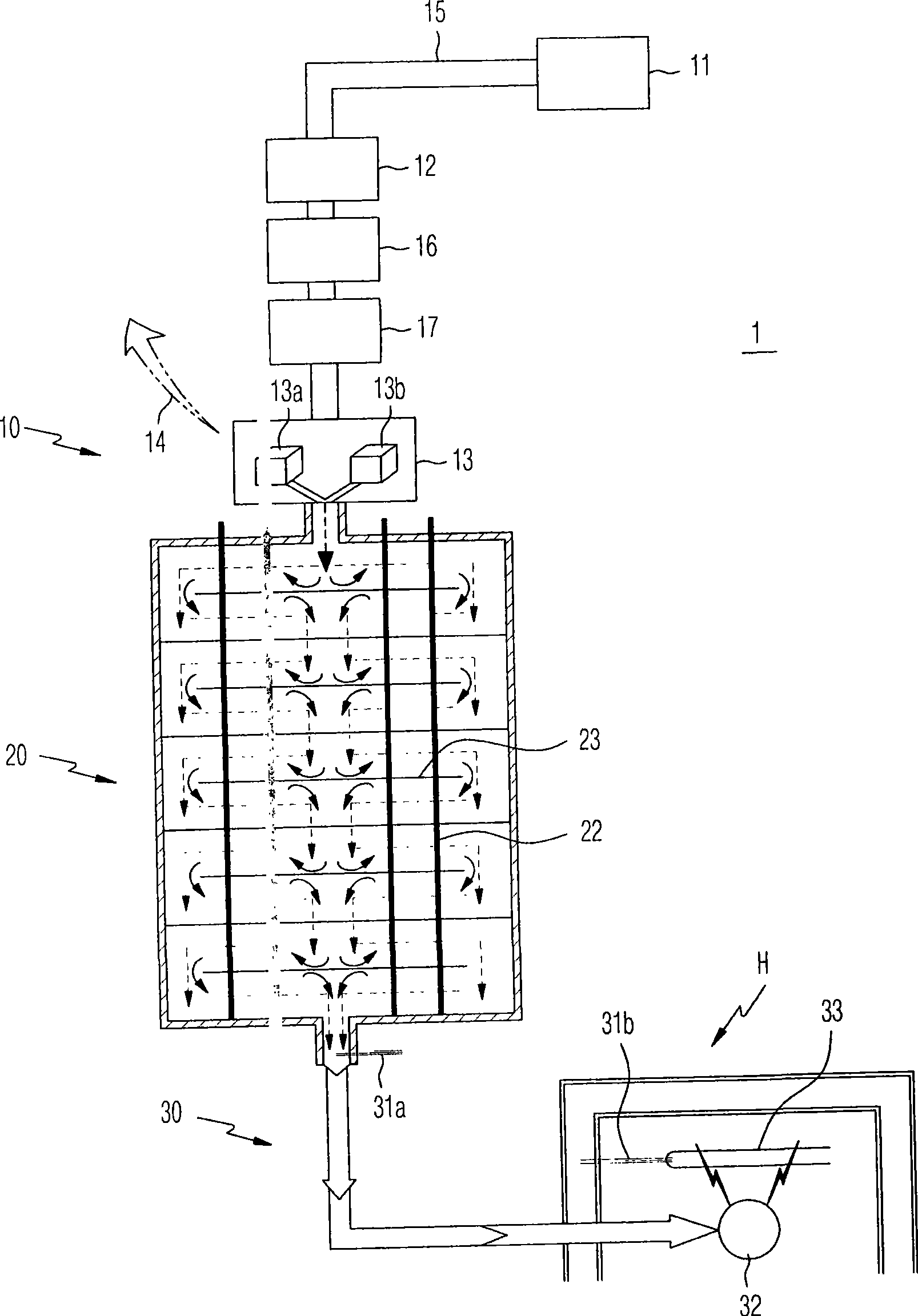

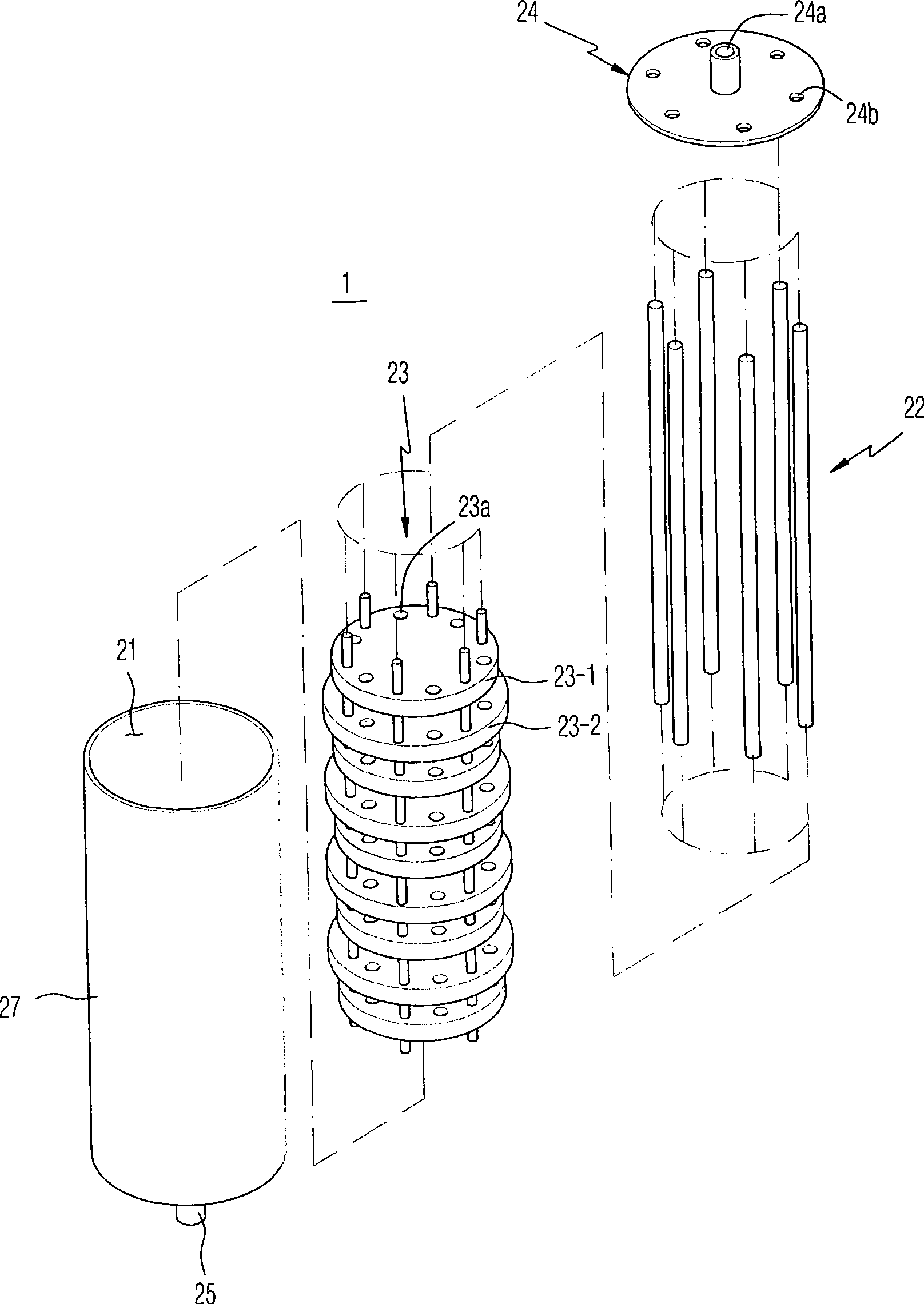

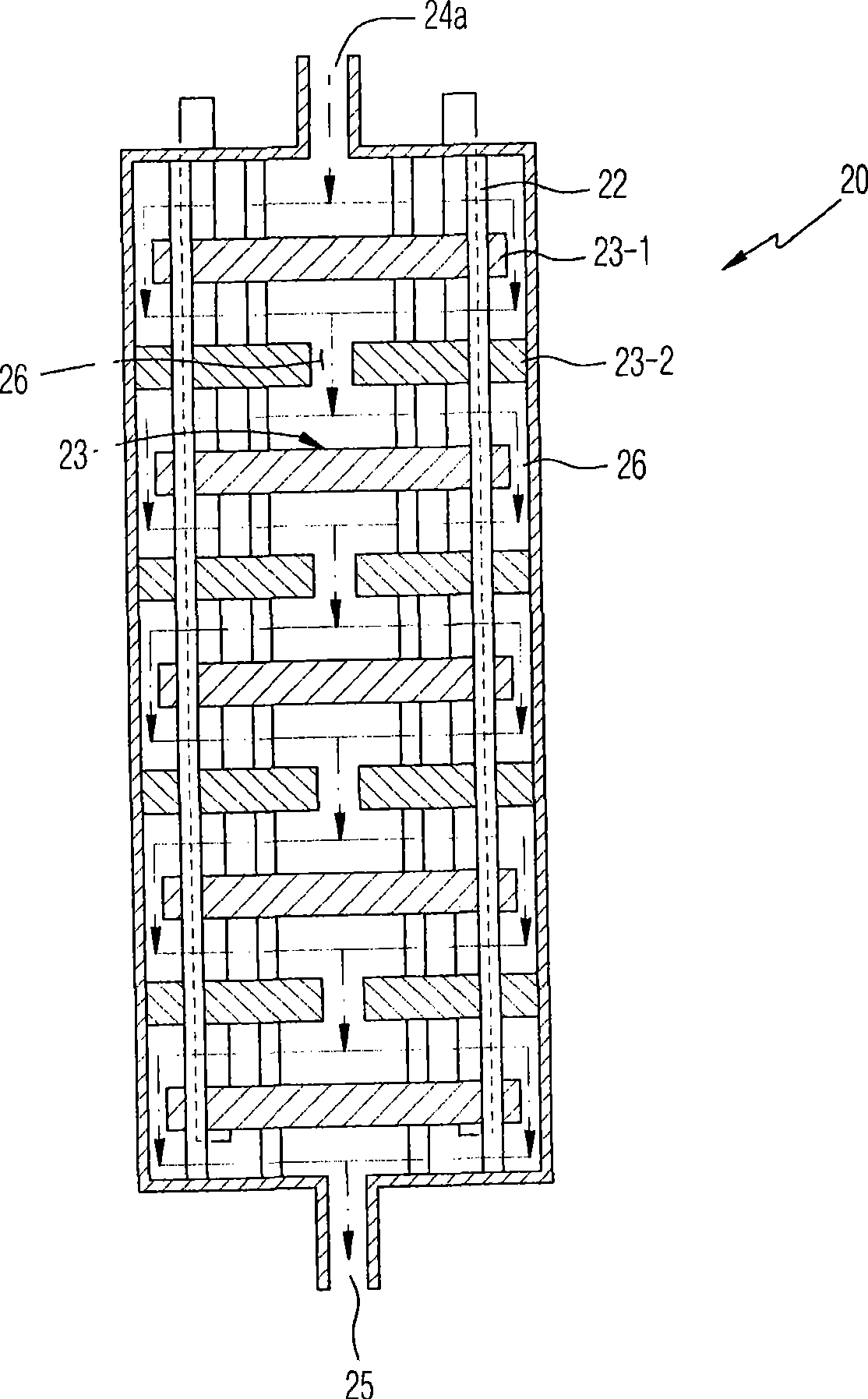

[0020] figure 1 is a conceptual diagram of a heating, sterilizing and drying appliance using a superheated steam generator according to the present invention in a disassembled state, figure 2 and 3 To illustrate top exploded perspective and cross-sectional views of a superheated steam generator according to the present invention, Figure 4 (a) and 4(b) are cross-sectional views illustrating a heating element of a superheated steam generator according to the present invention, and Figure 5 A cross-sectional view of a superheated steam injection line for illustrating a superheated steam supply line according to the present invention.

[0021] The heating, sterilizing and drying appliance using a superheated steam generator according to the present invention comprises: a saturated steam distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com