A heat exchanger with microchannels or/and thin channels on two or more sides

A thin-channel and micro-channel technology, applied in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as energy waste, increase fan output power, and short wind-side flow, and achieve optimal field Effects of synergistic effect, improvement of heat transfer coefficient, and improvement of temperature efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

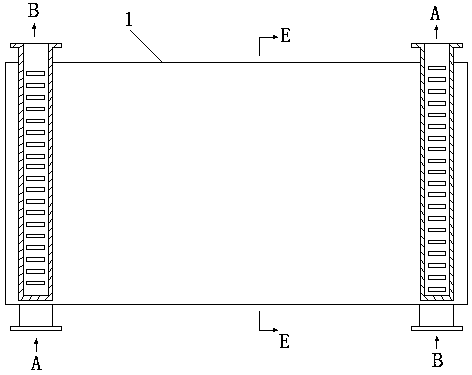

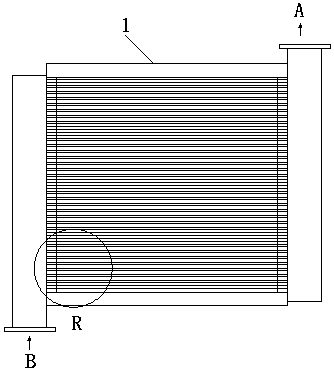

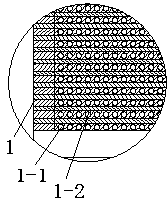

[0021] refer to Figure 1-3 , both sides of the present embodiment adopt the heat exchanger 1 of microchannel, comprise the microchannel 1-1 that is used for medium A to exchange heat and the microchannel 1-2 that is used for medium B to exchange heat, described heat exchanger 1 Adopt pure countercurrent heat exchange; the microchannels 1-1 for medium A for heat exchange and the microchannels 1-2 for medium B for heat exchange are both microchannels with a diameter of 0.5mm, and they are alternated in order Arranged in parallel, the inlet and outlet of the microchannel 1-1 for medium A to exchange heat and the microchannel 1-2 for medium B to exchange heat are respectively arranged on both sides of the channel in parallel arrangement, and the inlet passes through The horizontal distribution channel is connected with the corresponding channel, and the outlet is connected with the corresponding channel through the horizontal confluence channel. Of course, the microchannel may a...

Embodiment 2

[0024] refer to Figure 4-6 , the three sides of the present embodiment adopt the heat exchanger 2 of thin channel, and described heat exchanger 2 is provided with the circulation channel 2-1 that is used for medium A to exchange heat, and the circulation channel 2-1 that is used for medium B to exchange heat 2, there is also a circulation channel 2-3 for the medium C to exchange heat, which is characterized in that: the circulation channel 2-1 for the medium A to exchange heat, and the circulation channel for the medium B to exchange heat 2-2. The circulation channels 2-3 used for medium C to exchange heat all adopt thin channels with a diameter of 3 mm, and the rest are the same as in embodiment 1.

Embodiment 3

[0026] refer to Figure 7 , the two sides of the present embodiment adopt the heat exchanger 3 of microchannel, and the difference with embodiment 1 is: described microchannel inlet and outlet that is used for medium A to exchange heat does not have corresponding lateral distribution channel and confluence channel, and directly One end of the microchannel is connected with a channel cover I3-1, and the other end is connected with a fluid channel cover II3-2, which become the inlet and outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com